How Are Socket Wrenches Sized?

Socket wrenches are an essential tool that are used to tighten and loosen bolts and nuts. They come in various sizes depending on the size and type of the nut or bolt that needs to be secured or loosened. Socket sizes are typically measured in fractional inches, metric millimeters, or both.When selecting a socket wrench, it is important to choose the correct size to ensure that the job is done properly and safely. This article will explain how socket wrenches are sized and how to select the right size for the job.

Overview of Socket Wrenches

Socket wrenches are a versatile and indispensable tool for any mechanic or DIY enthusiast. They come in a variety of sizes and shapes, making them suitable for a range of applications. How are socket wrenches sized, and what type of socket wrench should be used for specific tasks? This blog post will provide an overview of socket wrenches and the different sizes available, as well as advice on how to select the right socket wrench for the job.

Socket wrenches come in a variety of sizes, from small ¼ inch sockets to large 2 inch sockets. The size of the socket is determined by the diameter of the nut or bolt that needs to be tightened or loosened. When selecting a socket wrench, it’s important to consider the size of the nut or bolt being worked on. A socket wrench that is too small may not be able to provide the necessary torque to loosen or tighten the nut or bolt, while a socket wrench that is too large may cause damage to the nut or bolt.

Socket wrenches are typically made of either metal or plastic. Metal socket wrenches are stronger and more durable, making them ideal for heavy-duty jobs. Plastic socket wrenches are lighter and more affordable, making them better suited for lighter duty tasks. It’s important to choose the right type of socket wrench for the job, as the wrong type of socket wrench could cause damage to the nut or bolt.

In addition to size and material, socket wrenches come in a variety of shapes. The most common are hexagonal, square, and torx. Hexagonal and square socket wrenches are suitable for a wide range of applications, while torx socket wrenches are mostly used for automotive applications.

Socket wrenches are an essential part of any toolkit, and the right socket wrench for the job can make a big difference in the quality and speed of the job. By understanding how socket wrenches are sized and the different types available, you can ensure that you have the right socket wrench for the job.

Types of Socket Wrenches

Socket wrenches come in a variety of sizes and types. These tools are great for loosening and tightening bolts and nuts, and can help make any job easier. But when it comes to choosing the right type of socket wrench for the job, it’s important to understand the different types available and how they are sized.

The most common type of socket wrench is the standard socket wrench. This type of socket wrench has a hexagonal shaped head and is available in a range of sizes, from 1/4” to 1/2”. They are designed to fit most nuts and bolts and are usually sold as a set. The size of the wrench is determined by the diameter of the head, so it’s important to know the diameter of the nut or bolt you’re working with before selecting the correct size.

Another type of socket wrench is the impact socket wrench. These wrenches have a longer handle and are designed to be used with an impact driver. The size of these wrenches is determined by the size of the hexagonal-shaped head. These wrenches are available in a range of sizes, from 3/8” to 1”.

Finally, there are metric socket wrenches. These wrenches have a six-pointed head and are designed for use with metric fasteners. They are available in a range of sizes, from 8mm to 25mm. As with other types of socket wrenches, the size is determined by the diameter of the head.

Understanding the different types of socket wrenches and how they are sized can help make any job easier. Whether you’re working with standard, impact, or metric fasteners, having the right socket wrench for the job is essential.

Factors that Determine Socket Wrench Size

Socket wrenches are essential tools for many different kinds of jobs, from automotive repairs to home improvement projects. But how do you know which size wrench to use? The answer lies in understanding the factors that determine the size of a socket wrench.

Socket wrenches are sized by the diameter of the opening they are designed to fit. The size of the wrench will be determined by the size of the nut, bolt, or fastener that needs to be removed or tightened. The most common sizes of socket wrenches are metric and standard, but there are also specialty tools that come in non-standard sizes.

The size of the socket wrench also depends on the type of use it is intended for. A larger wrench will be required for heavy-duty tasks, such as automotive repairs, while a smaller wrench will be sufficient for lighter tasks, such as furniture assembly.

The material used to make the socket wrench is another factor that affects its size. Wrenches made from more durable materials, such as stainless steel, will usually be larger than those made from softer materials, such as plastic.

Finally, the size of the socket wrench may also be affected by the type of fastener it is designed to fit. For example, a socket wrench made to fit a metric nut or bolt will have a different size than one made to fit a standard nut or bolt.

Knowing the factors that determine the size of a socket wrench can help you choose the right tool for the job. This will ensure that your work is done properly and safely.

Measuring Socket Wrenches

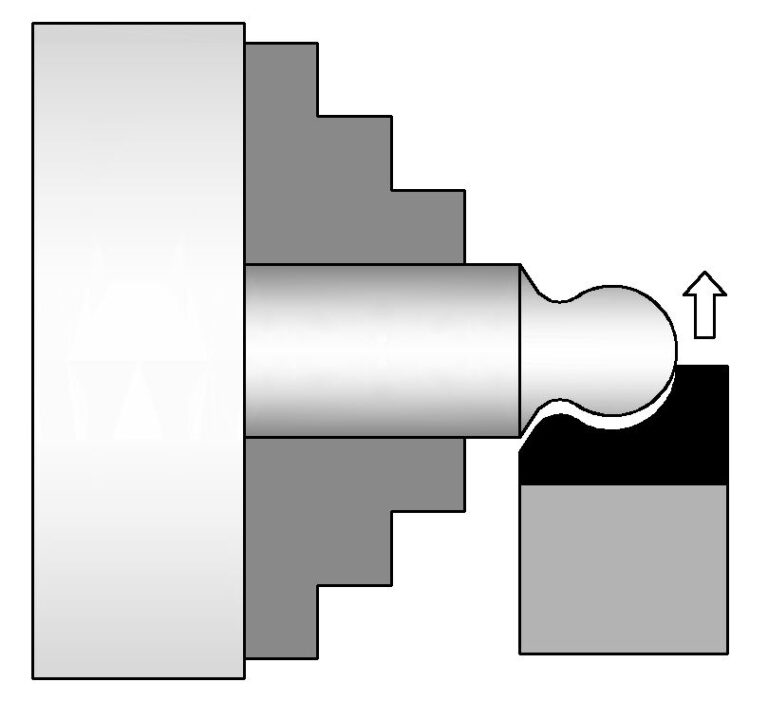

The size of a socket wrench is determined by two distinct measurements: drive size and socket size. Drive size is the width of the square-shaped drive end on the wrench, and socket size is the diameter of the socket that fits over the nut or bolt head.

When it comes to drive size, the standard sizes are 1/4, 3/8, 1/2, 3/4, and 1-inch. Socket sizes, on the other hand, are typically measured in metric and SAE (Society of Automotive Engineers) standards. The most common metric sizes are 4, 5, 6, 7, 8, 10, 12, 13, 14, and 15 millimeters. The most common SAE sizes are 5/32, 3/16, 7/32, 1/4, 5/16, 11/32, 3/8, 7/16, and 1/2 inches.

It’s important to note that socket wrenches are often labeled with both the drive size and socket size. This makes it easy to identify the size of the wrench, as well as to find a replacement or additional sockets.

When selecting a socket wrench, it’s important to make sure that the socket size matches the size of the nut or bolt head. If the socket is too large or too small, it won’t fit correctly and could lead to damage. It’s also important to make sure that the drive size is compatible with the socket wrench you’re using.

By understanding the sizing of socket wrenches, you can ensure that you have the right tools for the job. This will make it easier to complete tasks quickly and safely.

Advantages and Disadvantages of Socket Wrenches

Socket wrenches are incredibly handy tools that can be used to tighten or loosen nuts and bolts of varying sizes. But how are socket wrenches sized? Are there benefits and drawbacks to using them? In this blog, we’ll answer these questions and more as we explore the advantages and disadvantages of socket wrenches.

Socket wrenches are sized according to the size of the nut or bolt they are designed to fit. The size is indicated by the number of points, or “points of contact,” that the socket has. The more points of contact, the larger the nut or bolt that the socket can fit. In addition to size, socket wrenches are also classified by drive size — either a six-point, eight-point, or twelve-point socket.

The main benefit of using a socket wrench is that it can be used to tighten or loosen nuts and bolts of various sizes. It also requires less effort than using a standard wrench, as the socket is designed to fit securely onto the nut or bolt. The design of the socket also increases the torque that can be applied, making it easier to loosen stubborn nuts and bolts.

However, there are some drawbacks to using socket wrenches. For one, they are not as versatile as standard wrenches, as they are limited to a specific size of nut or bolt. Also, socket wrenches are more expensive than standard wrenches, making them a more expensive option. Finally, socket wrenches may be difficult to use in tight spaces, as they require more room to maneuver.

Overall, socket wrenches are a useful tool that can be used to tighten or loosen nuts and bolts of various sizes. They are more expensive than standard wrenches, but they offer the benefit of increased torque and require less effort. However, they are not as versatile as standard wrenches, and they may be difficult to use in tight spaces.

FAQs About the How Are Socket Wrenches Sized?

1. What is the difference between standard and metric socket sizes?

Answer: Standard socket sizes are measured in fractions of an inch, while metric socket sizes are measured in millimeters.

2. How do I know what size socket wrench I need for a particular job?

Answer: The size of the socket wrench you need will depend on the size of the nut or bolt you are trying to loosen or tighten. Make sure to check the size of the nut or bolt before selecting a socket wrench.

3. Are all socket wrenches the same shape and size?

Answer: No, socket wrenches come in different shapes and sizes. The most common types are 6-point and 12-point, which refer to the number of points on the socket.

Conclusion

Socket wrenches come in a wide variety of sizes, which can make it difficult to determine which one is the right size for a particular job. However, understanding the sizing scheme and the different types of sockets available can make the job much easier. For example, shallow sockets are best for fastener heads that are flush with the material, and deep sockets are better for fasteners that are recessed. Socket sizes are typically determined by the drive size and the width of the fastener head. It is important to choose the correct size socket for the job to ensure a secure fit and to avoid damaging the fastener head.