How Is PVC Size?

PVC size is the measure of the outside diameter of PVC pipe and fittings. It is important to know PVC size when determining what type of pipe and fittings to use for a particular project. PVC size is usually measured in inches and is most commonly available in 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, and 2″ diameters. The most commonly used sizes are 1/2″, 3/4″, and 1″. PVC size can also be determined by the pressure rating of the pipe, with higher pressure ratings indicating larger pipe diameters. Knowing the PVC size is essential when selecting the correct fittings and pipe for a project.

What is PVC Size?

PVC size is a measure of the size of a plastic pipe. It’s most commonly found in applications such as plumbing, irrigation, and drainage systems. PVC size is measured by the outside diameter of the pipe and is usually expressed in millimeters or inches. It’s important to understand what PVC size means, so you can make sure you get the right parts for your project.

PVC size is determined by the outside diameter of the pipe, and not by the inner diameter. This means that when you measure the PVC size, you must measure from the outside of the pipe. This is important to keep in mind when ordering parts, as the size of the pipe must match the size of the fittings. It’s also important to note that PVC size is not the same as the nominal size. Nominal size is the measurement of the pipe’s inside diameter, and is often used in reference to metal pipes.

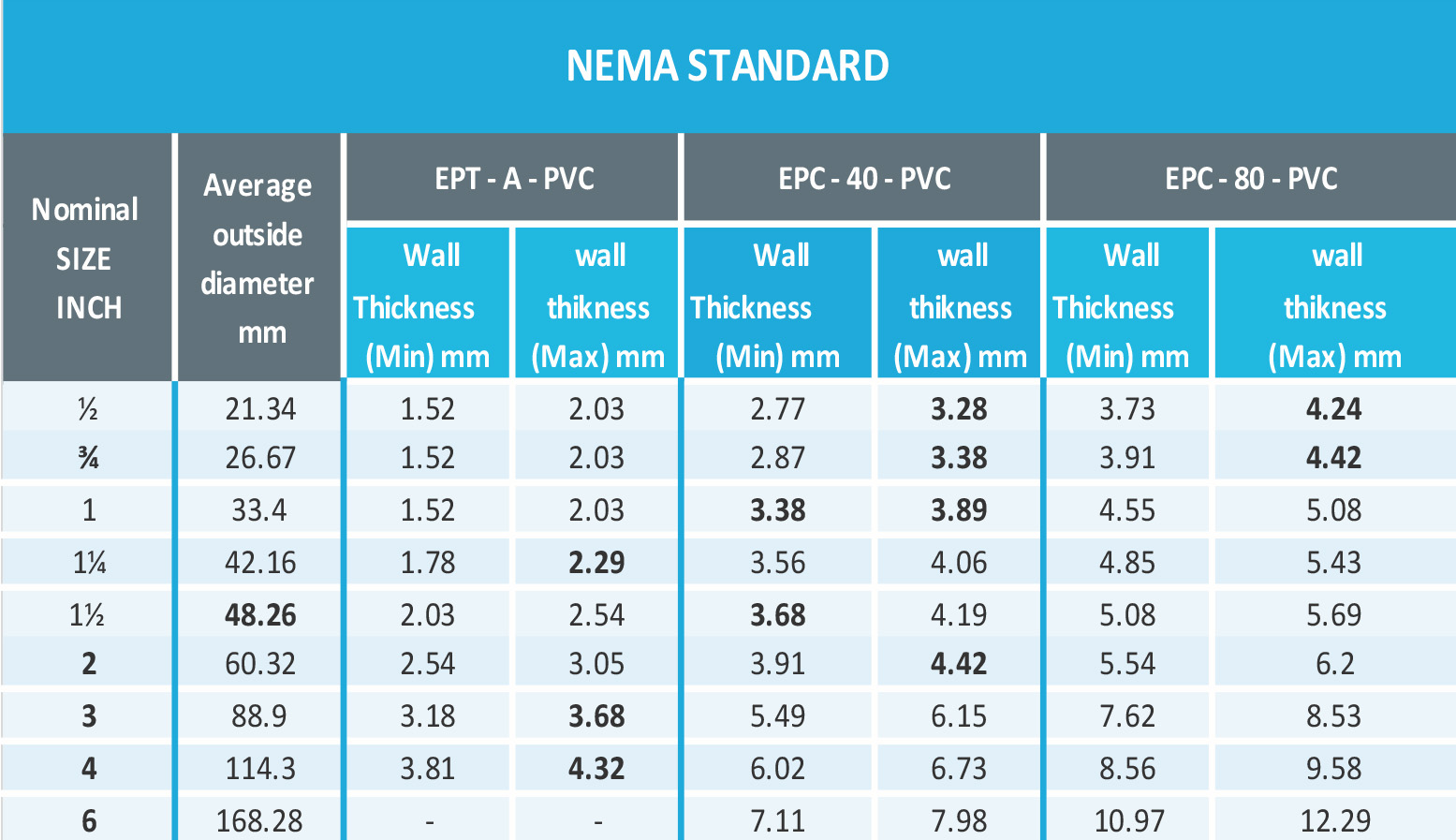

When it comes to PVC size, there are two commonly used sizing systems: Schedule 40 and Schedule 80. Schedule 40 PVC is the most commonly used in domestic and light commercial applications, and is generally the most cost-effective option. Schedule 80 PVC, on the other hand, is more durable and can withstand higher temperatures and pressures. It’s typically used in industrial applications.

Understanding PVC size is essential for any project involving plastic pipes. By understanding the difference between the two sizing systems, you’ll be able to choose the right parts for the job. Knowing PVC size also helps to ensure that the parts fit together correctly, and that the project will be safe and successful.

Types of PVC Sizes

PVC, or polyvinyl chloride, is a type of plastic used for a wide range of applications, including pipes, fencing, and even medical and industrial equipment. It is extremely versatile and can be made in a variety of sizes and shapes. Understanding which PVC size is best for your project is the key to successful results.

PVC is available in several different sizes, all of which are determined by the diameter of the pipe. The most common sizes include Schedule 40, 80, and 120, with each size having its own unique properties. Schedule 40 is the most common PVC size, and is used for most residential and commercial applications. It is strong and durable, and is best used for plumbing and drainage systems. Schedule 80 is a thicker pipe with a higher pressure rating, and is best used for certain industrial applications. Schedule 120 is the thickest pipe available, and is best used in specialty applications.

When selecting PVC, it is important to consider the size and type that best meet the needs of your project. The size of the pipe will determine the pressure rating, flow rate, and cost. Selecting the right PVC size will ensure that your project is completed with the best possible results.

How PVC Size is Measured

PVC size is a measure of the diameter of the pipe, which is used to determine the flow rate for liquids and gases. It is measured in inches and can range from 1/8 inch to up to 8 inches. The most commonly used PVC sizes are 1/2, 3/4 and 1 inch. These sizes are used for plumbing, irrigation, and water-flow applications.

When measuring PVC size, it is important to consider the inner diameter (ID) and outer diameter (OD). The ID is the actual size of the pipe, while the OD is the total circumference of the pipe. The OD will always be slightly larger than the ID, as the pipe walls have to be taken into account.

The most common method for measuring PVC size is to use a measuring tape or ruler. This will give you the exact size of the pipe and help you determine the best fit for your application. It is also possible to measure the pipe using a caliper, which is used to measure the precise diameter of a pipe. This is especially helpful when dealing with large-diameter pipes.

Knowing the exact PVC size is essential for ensuring proper flow and pressure in your system. By measuring the PVC size correctly, you can ensure that your system is functioning optimally and safely.

-min-1.jpeg?width=347&height=318&name=PVC-SIZE-DIMENSION%20(2)-min-1.jpeg)

Advantages of PVC Size

PVC size has become an increasingly popular choice for many applications due to its advantages. PVC size is strong, durable, and lightweight, making it ideal for use in a variety of projects. It is also resistant to corrosion and UV rays, making it an excellent choice for outdoor use. It is also easy to install and maintain, which makes it a cost-effective choice. Additionally, PVC size is available in a variety of sizes and shapes, making it a versatile material that can be adapted to fit any project. PVC size is also fire-retardant, meaning it can provide additional safety in areas where fire is a risk. Finally, PVC size is environmentally friendly and does not contain any hazardous chemicals. All of these advantages make PVC size a great choice for a variety of projects.

Disadvantages of PVC Size

PVC size, or polyvinyl chloride, is a popular material for many different uses due to its durability and flexibility. It is used in construction, plumbing, and other applications, but it also has many drawbacks. The material is not as strong as other materials, such as steel and wood, and it is not as resistant to water or other environmental factors. Additionally, PVC size is not a good insulator, meaning it does not keep heat or sound in or out. It can also be difficult to work with, as it requires specialized tools and techniques. In addition, PVC size can be more expensive than other materials. Therefore, it is important to consider all of the pros and cons before deciding whether or not to use PVC size for a particular application.

Common Uses for PVC Size

PVC size is a versatile material, with a variety of uses in both residential and commercial settings. PVC size is a durable material, that is highly resistant to corrosion and chemical damage. Due to its strength and flexibility, designers and builders rely on PVC size for a range of applications. In residential settings, PVC size is used for plumbing and sewer systems, decking, siding, and fencing. In commercial settings, PVC size is commonly used to create pipes, ducts, and electrical conduits. PVC size is also increasingly used in medical and laboratory settings, due to its ability to be sterilized and non-toxic properties. By utilizing PVC size for these applications, builders and designers can create high-quality, durable, and cost-effective structures. PVC size is an invaluable material, and its uses are sure to continue to expand as technology advances.

FAQs About the How Is PVC Size?

1. What is the standard PVC size?

Answer: The standard PVC size is 1/2 inch.

2. Is there any other size options available for PVC?

Answer: Yes, there are a variety of sizes available for PVC, ranging from 1/4 inch to 4 inches.

3. Does the size of PVC affect its durability?

Answer: Yes, the larger the size of the PVC, the stronger and more durable it is.

Conclusion

PVC size is an important factor to consider when selecting pipes for plumbing or other projects. It is important to know the right size of PVC pipe to ensure that it will fit the application correctly and safely. The size of PVC pipe can be determined by measuring the outside diameter of the pipe or by consulting manufacturer’s charts. Understanding the different sizes of PVC pipe and how to measure them can help ensure that the right size pipe is selected for the job.