How To Plumb Air Compressor Lines?

When plumbing air compressors, it is important to understand the components that are required in order to get the job done correctly and safely. The two most common components used in air compressor lines are copper pipes and air compressor fittings. Understanding the correct techniques for installing both of these components will ensure that your air compressor lines are properly plumbed and functional. This guide will provide a step-by-step process for plumbing air compressor lines, including the tools needed and the techniques used to ensure a successful installation.

What Equipment is Needed to Plumb Air Compressor Lines?

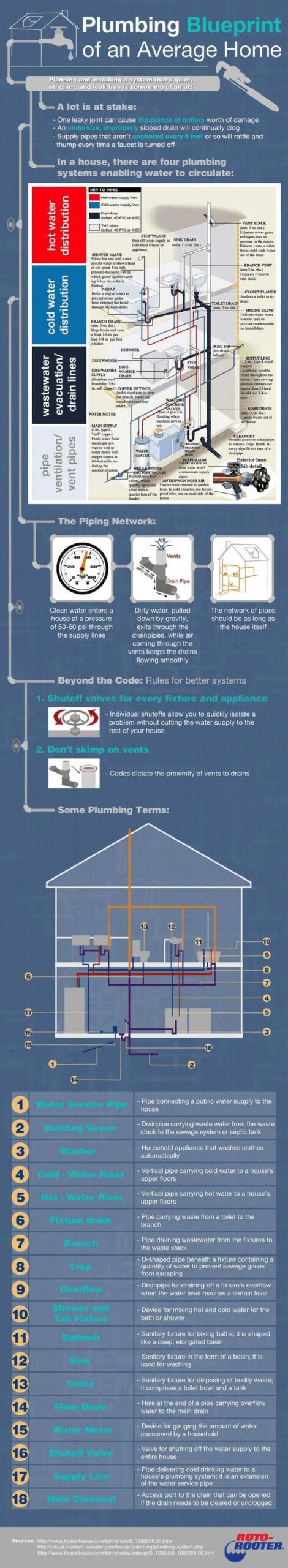

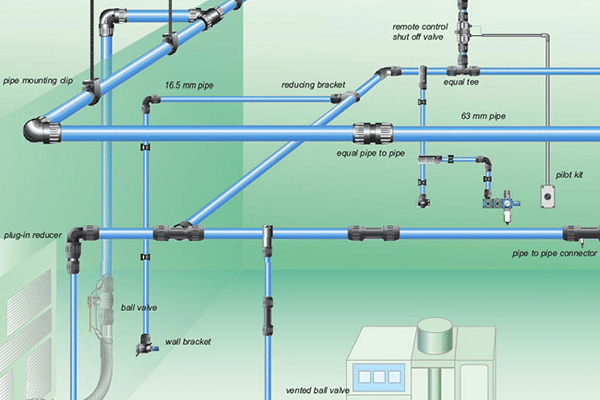

When it comes to plumb air compressor lines, the right equipment is crucial for a successful installation. To ensure that the project is a success, there are several tools and materials needed for the job. These include an air compressor, a pressure gauge, air line pipe, fittings, and valves.

An air compressor is the power source to drive air through the lines. Pressure gauges are used to monitor the air pressure and regulate flow. Air line pipe is used to connect the air compressor to the other components, while fittings and valves are used to control the flow of air. When connecting the components, it is important to use the correct size and type of pipe and fittings to ensure a secure and reliable connection.

It is also important to use the appropriate lubricants and sealants when plumb air compressor lines. Lubricants help to reduce friction between moving parts, while sealants prevent air from leaking from the connections. Having the correct sealants and lubricants can help to extend the life of the air compressor lines and prevent potential problems.

Finally, it is important to follow all safety precautions when plumb air compressor lines. This includes wearing the proper protective gear, such as goggles, gloves, and a face shield. It is also important to read and understand the instructions that come with the air compressor before attempting to install the lines. With the right equipment and safety precautions in place, plumb air compressor lines can be a successful and rewarding experience.

Safety Considerations for Plumbing Air Compressor Lines

Plumbing air compressor lines is a job that requires a careful and meticulous approach. While it may seem like a straightforward task, there are a few safety considerations that should be taken into account before beginning the project. First, it’s important to make sure that the air compressor lines are properly secured and that all connections are tight. Additionally, ensure that all air fittings are the correct size and that the correct materials, such as copper, are used for the installation. It is also important that you are aware of the maximum pressure of the system before beginning the project.

It is also essential that all safety equipment is used while plumbing air compressor lines. This may include gloves, safety glasses, and a respirator. Additionally, ensure that the work area is well ventilated and that all tools are in good working condition. Finally, never work alone when plumbing air compressor lines, even if you are experienced in the task. It is always best to have a second person on hand to help.

By following these safety considerations, you can ensure that your air compressor lines are properly plumbed and that the job is done safely. Taking the time to consider your safety is essential when plumbing air compressor lines.

Installing and Connecting the Air Compressor Lines

Installing and connecting the air compressor lines is a crucial step in ensuring a reliable, efficient, and safe operating environment. With the right tools and knowledge, it’s not difficult to install and connect air compressor lines. Before beginning the process, however, it’s important to understand the types of materials used, the installation process, and the maintenance requirements.

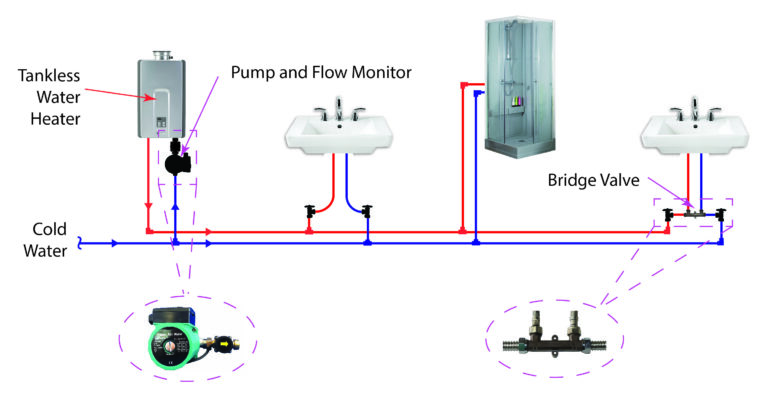

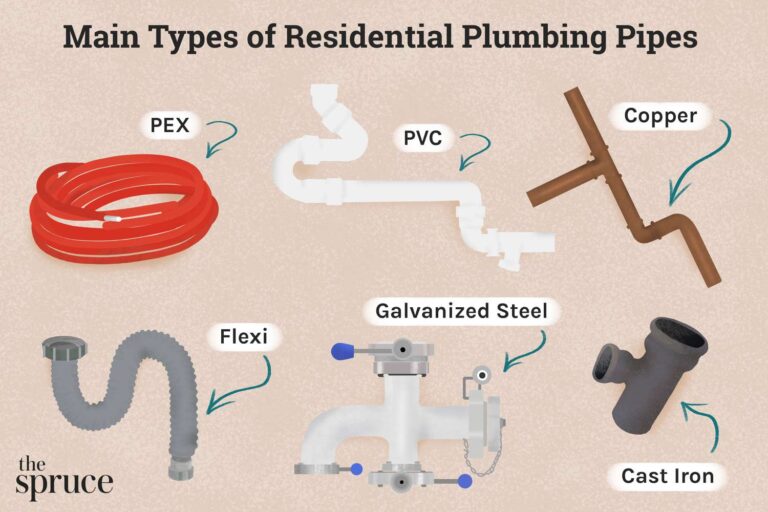

Materials used for air compressor lines include metal, such as steel or copper, or plastic, such as PVC or polyethylene. Each material has its own advantages and disadvantages, and it’s important to research the type of material best suited to your needs before beginning the installation process.

The installation process involves connecting the air compressor lines to the main air compressor line, securing them with clamps and fittings, and ensuring that the lines are properly sealed and airtight. It’s also important to use the correct type of fittings and seals to ensure that the air compressor lines are securely connected.

Finally, good maintenance practices are essential to ensure that the air compressor lines remain in good condition. Regularly checking for signs of wear and tear, leaks, and other damage is crucial to maintain the efficiency of the system. Additionally, it’s important to replace components as needed to ensure that the air compressor lines remain fully functional and safe to use.

Testing the Compressor Line System

Testing the air compressor line system is an important step to ensure that it is in proper working condition. To test the system, turn on the compressor and check the pressure gauge. If the pressure is within the specified range, then the system is working correctly. If the pressure is not as expected, then there could be a problem with the system.

Inspect the air compressor lines for any signs of wear and tear. Check for any kinks or bends in the line, as this could lead to a leak. Make sure that all fittings and connections are secure and tight. Also, look for any signs of rust or corrosion, which could also cause a leak.

If the system is still not working, then you may need to replace the air compressor lines. Make sure to buy the correct size and type of pipe or hose for your air compressor. It is generally best to purchase the same type of pipe or hose as the old line. Once the new line is installed, test the system again and make sure that the pressure is within the specified range.

By checking the air compressor lines regularly and replacing them as needed, you can ensure that your air compressor system is working as efficiently and effectively as possible.

Troubleshooting and Maintenance of Air Compressor Lines

Air compressor lines are essential components of any pneumatic system, but they can also be prone to issues. Regular troubleshooting and maintenance of air compressor lines is essential in order to ensure that the system is working optimally and that there are no preventable problems. In this article, we will discuss how to properly plumb air compressor lines, as well as ways to troubleshoot and maintain them.

Properly plumbed air compressor lines are essential for efficient operation and performance. Plumbing involves connecting air compressor lines to other components in the system, such as valves, tanks, and regulators. It is important to ensure that all connections are secure and that the pressure is set to the correct level. To do this, it is important to use the right tools and materials, such as Teflon tape, clamps, and gaskets.

When it comes to troubleshooting and maintaining air compressor lines, it is important to inspect them regularly. Check for signs of wear and tear, such as cracks or corrosion. It is also important to ensure that all connections are secure and that the pressure is at the correct level. If any issues are detected, it is essential to take corrective action as soon as possible to avoid more serious problems down the line.

Overall, proper plumbing and regular maintenance of air compressor lines is essential for the proper functioning of any pneumatic system. By following the steps outlined above, you can ensure that your system is functioning optimally and that there are no preventable issues.

FAQs About the How To Plumb Air Compressor Lines?

1. What type of pipe should I use to plumb air compressor lines?

Answer: For most home and small business applications, galvanized steel pipe is an appropriate choice for air compressor lines. For larger commercial applications, black steel pipe is recommended.

2. How should I secure the pipe joints?

Answer: To ensure a secure connection, pipe joints should be sealed with pipe thread sealant and secured with threaded pipe fittings and/or clamps.

3. What size pipe should I use for my air compressor lines?

Answer: The size of the pipe should be based on the requirements of your compressor. Generally, the pipe should be large enough to handle the volume of air that the compressor is able to produce. You should consult the manufacturer’s specifications for the recommended size of pipe.

Conclusion

In conclusion, plumbing air compressor lines can be a daunting task, but with the right tools and knowledge it can be a relatively simple process. With the proper planning and preparation, it is possible to install the lines correctly and effectively. It is important to research the specifics of your project and make sure that you understand the safety measures and precautions that need to be taken. By following the steps outlined in this article, you will be able to successfully complete the project and enjoy the benefits of having a reliable and efficient air compressor system.