What Does PVC Stand For?

PVC stands for Polyvinyl Chloride, a type of plastic polymer commonly used in piping, insulation, and other construction materials. PVC is popular for its affordability, durability, and resistance to corrosion and weathering. It is also easy to work with and can be cut, formed, and joined with other materials such as metal or wood. PVC is often used in sewer and water lines, roofing membranes, and even toys.

Overview of PVC

PVC is one of the most widely used materials in the world. It stands for Polyvinyl Chloride, a type of plastic which is incredibly versatile and can be used in a variety of applications. PVC is a strong, durable, and lightweight material which is resistant to corrosion, moisture, and weathering, making it suitable for both indoor and outdoor use. It is also easy to cut, shape, and join, making it ideal for a range of construction projects. PVC is also recyclable and can be used to fabricate a variety of products, including pipes, windows, siding, fencing, and more. It is an economical and environmentally friendly option for a range of applications.

History of PVC

PVC, or polyvinyl chloride, is an incredibly versatile and widely used material in the modern world. It has been used in a variety of ways since the early 20th century, and has become a standard material for many applications. The history of PVC is fascinating, beginning with its discovery as a synthetic material in the late 19th century. In the 1930s, the first PVC resins were created, and in the 1950s, PVC was used as a plasticizer for rubber products. In the decades that followed, PVC was widely used in construction, furniture, and even clothing. Today, PVC is one of the most commonly used plastics in the world, and its applications continue to expand. From plumbing pipes to medical supplies, the history of PVC is a testament to its incredible versatility and usefulness.

Manufacturing Process of PVC

PVC (Polyvinyl Chloride) is a versatile plastic material that is used in many everyday items. From water pipes to window frames, it is a widely used material due to its durability, low cost, and ease of production. The manufacturing process of PVC involves several stages, beginning with the production of the raw material, which is then compounded and extruded into the desired shape. The material is then cooled, cut, and packaged for delivery. During the process, additional materials such as stabilizers, lubricants, and colorants can be added to enhance the PVC and make it suitable for specific applications. With its broad range of properties, PVC is a popular choice for many industrial and consumer products.

Benefits of Using PVC

PVC (polyvinyl chloride) is a popular material used to make a variety of products, from pipes to furniture, due to its versatility and durability. It has many advantages that make it an ideal choice for a wide range of applications.

PVC is lightweight, making it easy to transport and handle. It is also cost-effective compared to other materials, making it a great option for large-scale projects. Additionally, it is waterproof and resistant to most chemicals, making it a good choice for areas with frequent exposure to water or harsh chemicals.

Moreover, PVC is very easy to maintain and clean, making it ideal for use in areas that require frequent cleaning or sanitization. It is also flame retardant and provides good insulation against sound and heat, making it suitable for use in many different environments.

In short, PVC is a great choice for many applications due to its lightweight, durability, and cost-effectiveness. It is also easy to maintain and provides good insulation against sound and heat, making it an ideal option for many different purposes.

Disadvantages of Using PVC

PVC, or polyvinyl chloride, is a popular material used in many construction and manufacturing applications. However, despite its popularity, there are several disadvantages to using PVC. One disadvantage is that PVC contains numerous toxic chemicals, including lead and phthalates, which can have a negative impact on the environment if not disposed of properly. Additionally, PVC is not biodegradable, and it can take hundreds of years to decompose, leading to a buildup of plastic waste in landfills. PVC is also a relatively expensive material, and its production can release large amounts of carbon dioxide emissions. Finally, PVC is not as durable as some other materials, and can be prone to cracking and warping over time.

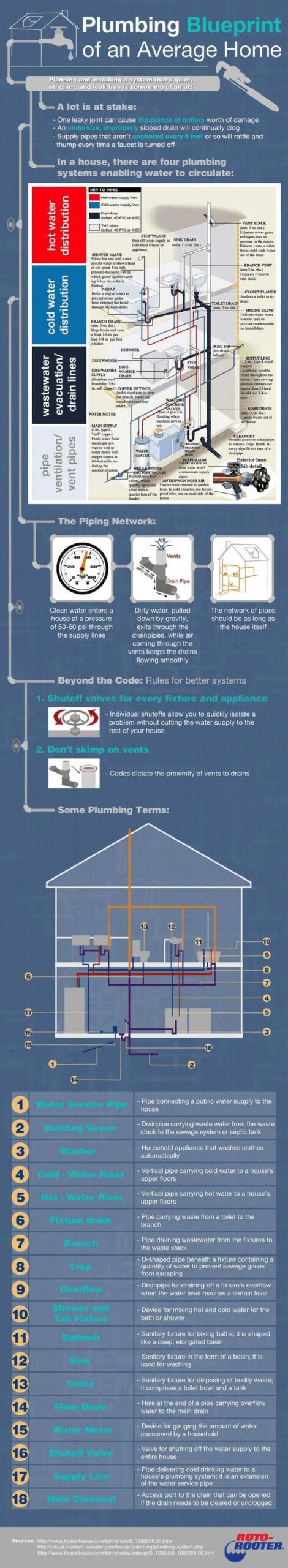

Applications of PVC

PVC (polyvinyl chloride) is a popular building material due to its strength, durability, and affordability. It is most often used in construction, but there are many other uses for this versatile material. PVC can be used in a variety of applications, from medical equipment to home decor. For instance, PVC can be used to make pipes, tubing, window frames, and even flooring. In the medical field, PVC is commonly used for x-ray equipment, IV bags, and oxygen masks. It is also used to construct tanks, storage containers, and even furniture. PVC is lightweight, flexible, and resistant to corrosion and chemicals, making it an ideal choice for many applications. For those looking to add a unique touch to a living space, PVC can be used to create unique wall coverings, furniture, and accessories. With its versatility and affordability, PVC is a great choice for both professional and home projects.

FAQs About the What Does PVC Stand For?

Q1: What does PVC stand for?

A1: PVC stands for Polyvinyl Chloride.

Q2: What is PVC used for?

A2: PVC is widely used in construction and manufacturing due to its low cost, durability, and versatility. It is commonly used for pipes, siding, window frames, flooring, and other applications.

Q3: Is PVC environmentally friendly?

A3: PVC is not considered to be an environmentally friendly material because it contains toxic additives and can release harmful chemicals when burned. It is also not biodegradable.

Conclusion

In conclusion, PVC stands for Polyvinyl Chloride, a type of thermoplastic polymer commonly used in construction materials and other products. PVC is very durable, lightweight, and inexpensive, making it an ideal material for many applications. It is also resistant to many types of chemicals and is a popular choice for plumbing and electrical installations.