What Is A Leak Valve?

A leak valve is a device that is designed to detect and control the flow of liquids or gases. It is typically used in industrial applications to control the rate of flow of a medium, such as oil or gas, through a system. The leak valve is designed to open and close in response to changes in the pressure or flow rate of the medium. It is also used to prevent leaks and to maintain a safe operating pressure within a system. Leak valves are available in a variety of designs, including check valves, needle valves, and butterfly valves, and can be made from a range of materials, such as brass, stainless steel, and thermoplastics.

Definition of a Leak Valve

A leak valve is a device used to control the flow of a fluid. It is designed to open and close in response to changes in pressure, temperature, or other factors. The valve is typically used in pipelines, tanks, and other vessels to regulate and manage the flow of liquids or gases. Leak valves are primarily used to prevent and reduce the risk of leaks or spills in industrial and commercial settings.

Leak valves are typically designed to operate automatically, meaning they open and close in response to pressure changes within the system. This is achieved by using a variety of sensors, such as pressure, temperature, and flow rate. The valve can also be manually controlled, allowing for manual adjustment of the flow rate. The materials used to construct the valve are also important, as they must be able to withstand the pressure and temperature of the fluid.

Leak valves are an important safety feature in many industries, as they help to prevent spills and other hazardous conditions. They are also used to ensure that process systems, such as pipelines and tanks, remain at optimal operating conditions. Leak valves are designed and manufactured to meet the specific needs of each application, and their operation should be regularly monitored to ensure they are functioning properly.

Types of Leak Valves

Leak valves are an essential component of many industrial systems. They are designed to protect pipelines, tanks, and other equipment from pressure spikes and leaks. A leak valve can be a simple check valve, a pressure relief valve, a rupture disk, or a combination of these. All of these types of valves are used to prevent loss of pressure or to protect against an overpressure condition.

Check valves are used to allow liquid or gas to flow in one direction only, to prevent backflow. Meanwhile, pressure relief valves are designed to open when pressure reaches a certain level, releasing the excess pressure and preventing equipment from being damaged. Rupture disks are designed to be used in high pressure systems. They are made of a thin metal disk that will burst when the pressure inside reaches a certain level, allowing the excess pressure to be released.

These types of valves are used in a variety of industrial applications. They can be used to protect pipelines, tanks, boilers, and other equipment from pressure spikes and leaks. They are also used to regulate the pressure and flow of fluids in a system. Leak valves can be used in many different industries, including oil & gas, chemicals, and water treatment. They are designed to be strong and durable, so they can withstand the harsh conditions of these industries.

Leak valves are an essential component of many industrial systems, and they can help to keep equipment and pipelines safe. They are designed to prevent pressure spikes and leaks, and they come in many different types. Choose the right type of valve for the job, and you can ensure that your system is running safely and efficiently.

Benefits of Using a Leak Valve

Leak valves are an important component of any plumbing system, and they have many benefits. A leak valve is a device used to control the flow of water in a plumbing system, preventing any leaks from occurring. This can be a valuable tool when it comes to preventing water damage, saving money on water bills, and protecting the environment. Leak valves are also designed to be easy to install and maintain, and many are designed to be adjustable or replaceable.

Leak valves can also be used to help regulate the temperature of water in a plumbing system, as they can be used to reduce or increase the flow of water. This can be beneficial in ensuring that the water temperature remains consistent throughout the system, ensuring that the water is always at a comfortable temperature for the user.

When it comes to safety, a leak valve is a great tool for preventing leaks and potential water damage. By controlling the flow of water, a leak valve can help prevent flooding or water overflow. This can be especially beneficial in areas prone to flooding or areas where water pressure is high.

Leak valves can also be used to help reduce water bills. By controlling the flow of water, a leak valve can help reduce the amount of water used in a plumbing system, resulting in lower water bills. This can be especially beneficial for households or businesses that use a lot of water on a daily basis.

Overall, leak valves are a great tool for any plumbing system, offering a wide range of benefits. They are easy to install and maintain, and they can help prevent water damage, save money on water bills, and help regulate the temperature of the water.

How to Install a Leak Valve

A leak valve is an important component of any plumbing system, as it helps to prevent water damage caused by a faulty pipe or fixture. Installing a leak valve can be a straightforward process, but it is important to be aware of any potential complications that could arise during installation.

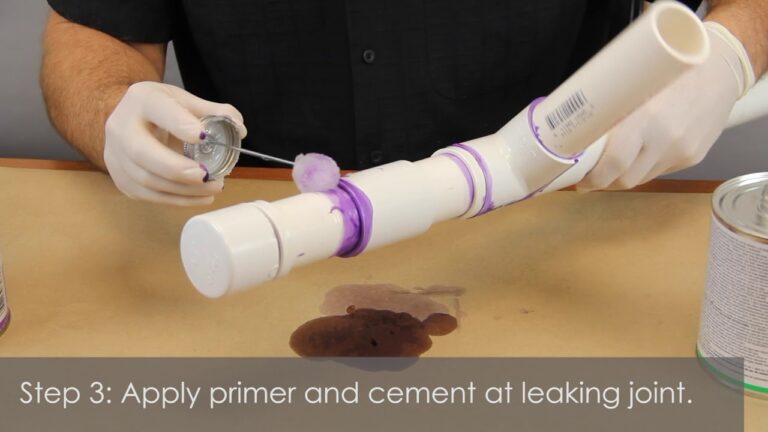

The first step in installing a leak valve is to identify the pipe or fixture that needs to be protected. Once identified, the leak valve should be connected directly to the pipe or fixture using the appropriate fittings and connections. If the installation requires cutting into a pipe or fixture, it is important to make sure that the cut is made cleanly and that any necessary sealing or caulking is done properly.

Once the leak valve is connected, it is important to check for any potential leaks or air bubbles in the system. This can be done by using a pressure gauge or other testing device. If any leaks or air bubbles are detected, they should be addressed immediately.

Finally, the leak valve should be tested to ensure that it is functioning properly. This can be done by opening the valve and allowing water to flow through it. If the water pressure is consistent and the valve is not leaking, then the installation is complete.

Installing a leak valve is an important part of any plumbing system and can help to protect against costly water damage. By following the steps outlined above, homeowners can ensure that their leak valve is installed correctly and is functioning properly.

Troubleshooting Common Leak Valve Issues

Leaks are an all too common occurrence in many homes and businesses, and leak valves can be a great way to help prevent costly and time-consuming repairs. A leak valve is a device that helps to control the flow of liquids, gases, and other materials. It is designed to shut off the flow of fluid or gas when the pressure exceeds a certain level. Leak valves are commonly used in plumbing, gas systems, and other industrial applications.

When it comes to troubleshooting leak valves, it is important to check for common issues such as blocked or blocked valve seats, worn out or corroded parts, and improper installation. Additionally, it is important to inspect for signs of leakage, such as visible water or gas escaping from the valve, and to pay attention to any noises coming from the valve. If the valve is not functioning correctly, it may be necessary to replace it with a new one.

It is also important to be aware of any safety considerations when dealing with leak valves. For example, when dealing with gas systems, it is important to turn off the main gas supply before attempting to repair a leak valve. Additionally, when replacing a leak valve, it is important to follow the manufacturer’s instructions for proper installation.

By understanding the basics of leak valves and being aware of the common issues that may arise, it is possible to diagnose and resolve problems quickly and safely. With the right knowledge and tools, troubleshooting a leak valve can be a relatively straightforward process.

FAQs About the What Is A Leak Valve?

1. What is the purpose of a leak valve?

A leak valve is designed to detect and stop the flow of liquid or gas in a pipe or container, usually as a result of a pressure drop. This helps to prevent damage to the system and any hazardous material from escaping.

2. What types of materials are used to make a leak valve?

Leak valves are usually made of metal, such as stainless steel or aluminum, due to their strength and durability. Other materials such as plastic, rubber, and brass can also be used for certain applications.

3. How does a leak valve work?

A leak valve works by detecting a pressure drop in the pipe or container. When this happens, the valve will close to stop the flow of liquid or gas and prevent any hazardous material from escaping.

Conclusion

A leak valve is a device used to control the flow of liquids and gases. It is designed to allow a certain amount of material to pass through while preventing excessive flow. Leak valves are used in a variety of industries and for a variety of applications, including chemical processing, petrochemical refining, and plumbing. They are essential components in maintaining a safe working environment and ensuring the proper functioning of various systems.