What Is A Manifold In Plumbing?

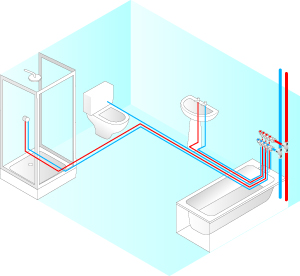

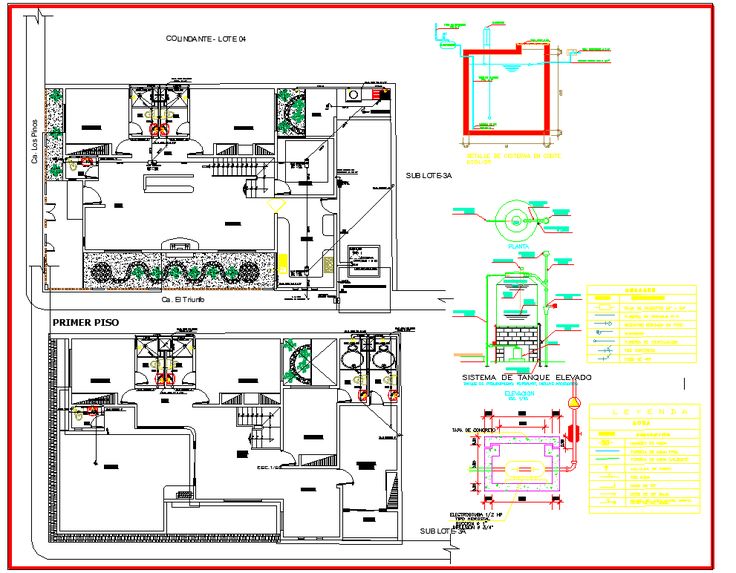

The plumbing manifold is a centralised distribution system for hot and cold water used to supply all the plumbing fixtures in a home. It is usually located near the water heater and is made up of a series of valves, shut-off valves, and ports that control the flow of water to each individual plumbing fixture. A manifold makes it easy to shut off the water to individual fixtures or an entire section of the house, while still allowing water to flow to other fixtures. It also helps to conserve water by ensuring that all fixtures are supplied with the same pressure and temperature of water.

Definition of a Manifold

A manifold is a mathematical object that encapsulates a large number of points into a single, unified structure. It is a topological space that is made up of a set of points, each of which is connected to the others in some way. Manifolds are used in a variety of ways, including in mapping, physics, and computer science. They are versatile and powerful tools that allow for the complex analysis of multiple variables in a single system. Manifolds can be thought of as a “multi-dimensional space”, allowing for the exploration of intricate relationships between different points within the space. They are an invaluable asset to scientists and mathematicians everywhere.

Types of Manifolds

Manifolds are a type of mathematical structure that can be used to describe the shape and structure of space. There are several different types of manifolds, each with its own unique properties and applications. The most commonly encountered type of manifold is the Euclidean manifold, which is used to describe flat, or two-dimensional spaces. This type of manifold is used in many areas of mathematics, including calculus, linear algebra, and topology. Other types of manifolds are the Riemannian manifold, which is used to describe curved, or three-dimensional spaces, and the projective manifold, which is used to describe higher-dimensional spaces. Each of these types of manifolds has unique properties and applications in mathematics, making them essential tools for understanding the structure of space.

Benefits of Manifolds

Manifolds are high-precision components designed to connect multiple pipes and tubes in a single unit. They offer a number of advantages, including increased space efficiency, improved safety, and enhanced system performance. By using a manifold, you can minimize the number of connections required and reduce the number of components in the system, making it easier to install and maintain. Manifolds also reduce the risk of leaks, as there are fewer points of potential failure, and they can also reduce the amount of time and energy required to heat or cool a pipe or tube. Additionally, using a manifold in your system can improve system performance, as it can help to reduce vibration and turbulence, allowing for smoother, more efficient flow.

Installing a Manifold

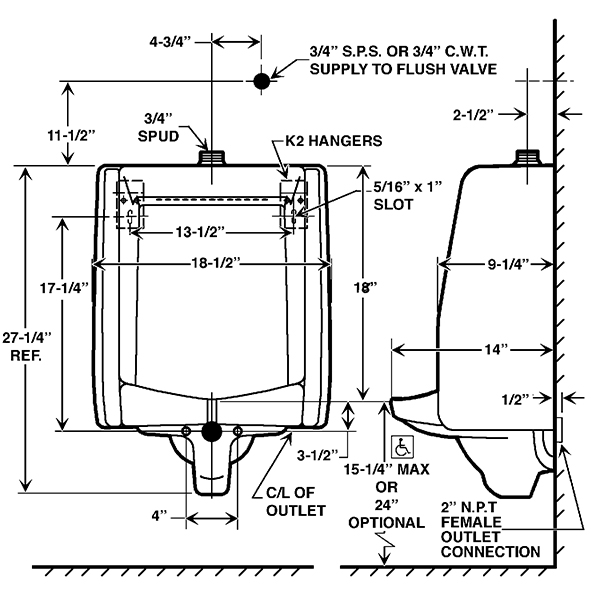

Installing a Manifold is an important step in the plumbing process for any home or business. It is typically used to unify a number of water lines, so that multiple fixtures can be connected to the same supply. It is important to make sure that the manifold is installed correctly to ensure a safe and secure plumbing system. It is also important to choose the right size manifold for the job, as too large a manifold can cause loss of pressure, while too small will reduce water flow. The process of installing a manifold typically requires measuring, cutting, soldering, and connecting the pipes but can be completed in a few hours with the right tools and know-how. With the right preparation, installing a manifold can be a straightforward and efficient process.

Maintenance of a Manifold

Maintenance of a Manifold is essential to keep any system running smoothly. It involves the inspection of the manifold, the cleaning of any debris, the removal of any corrosion, and the replacement of any parts that have worn out or been damaged. The manifold is an important component of any system, as it helps regulate the flow of liquid and gas throughout the system. Without proper maintenance, the manifold may gradually become blocked or corroded, leading to decreased efficiency and potential damage to the system. Regular maintenance of the manifold is essential for any system to run at optimal levels.

Common Problems with Manifolds

Manifolds are an integral part of any plumbing system, but they can also present a number of potential problems. Common issues include leaky joints and fittings, corroded valves, clogged pipes, and inadequate pressure. Leaky joints and fittings can occur when the materials used are not compatible with the pipe or the connection is not properly sealed. Corroded valves can cause water pressure to drop, resulting in a lack of water flow. Clogged pipes can reduce water flow and cause blockages. Lastly, inadequate pressure can limit the amount of water that comes out of the taps. Proper maintenance and regular checks can help avoid or mitigate these common problems with manifolds.

FAQs About the What Is A Manifold In Plumbing?

1. What is a manifold in plumbing and why is it used?

A manifold is a plumbing fitting that is used to distribute water from one source to multiple locations. It is made up of many individual valves and pipes that can be opened and closed to regulate the flow of water.

2. How is a manifold installed?

A manifold is typically mounted on the wall and connected to your existing plumbing system. It is important to ensure that the manifold is connected correctly to ensure that water flows freely.

3. How often should a manifold be inspected?

It is recommended that a manifold be inspected at least once a year to ensure that there are no blockages or leaks. If any issues are found, it is recommended that a qualified plumber be consulted to carry out any necessary repairs.

Conclusion

A manifold is an essential component of a plumbing system, allowing for multiple water lines to be connected in a single location. By allowing multiple water lines to be connected, it simplifies installation, and makes it easier to access individual lines for maintenance or repairs. It is important to ensure that the manifold is installed correctly to ensure proper water flow and pressure throughout the system.