What Is A System Piping?

System piping is a type of mechanical engineering that involves the installation, maintenance, and repair of a variety of pipelines and related equipment. It’s used to transport various fluids or gases, such as water, steam, oil, and natural gas. System piping is a key component of many industrial and commercial operations, as it helps ensure that these processes run smoothly and safely. System pipers must be knowledgeable in a variety of principles and technologies, such as welding, hydraulics, and thermodynamics.

Definition of System Piping

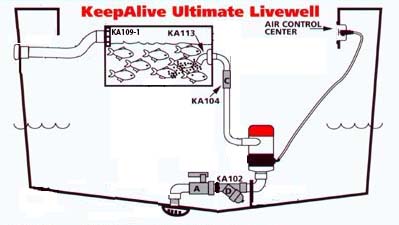

System piping is a type of piping system used to move fluids or gases from one location to another. It is composed of pipes, valves, pumps, and other components. System piping is designed to transport liquids and gases in a safe and efficient manner, while also meeting specific requirements for pressure, temperature, and flow. This type of piping is commonly used in industrial applications and for fuel, air, and cooling systems in automobiles. System piping is also used for water supply and wastewater systems in residential and commercial buildings. It is essential for proper functioning of heating and cooling systems, as well as for fire suppression systems and other safety measures. System piping is essential to the safe, efficient operation of many different types of systems and is designed to last for many years.

Components of System Piping

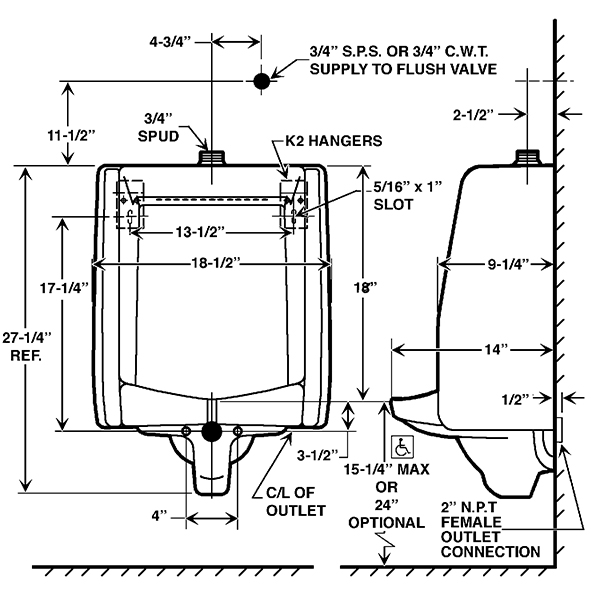

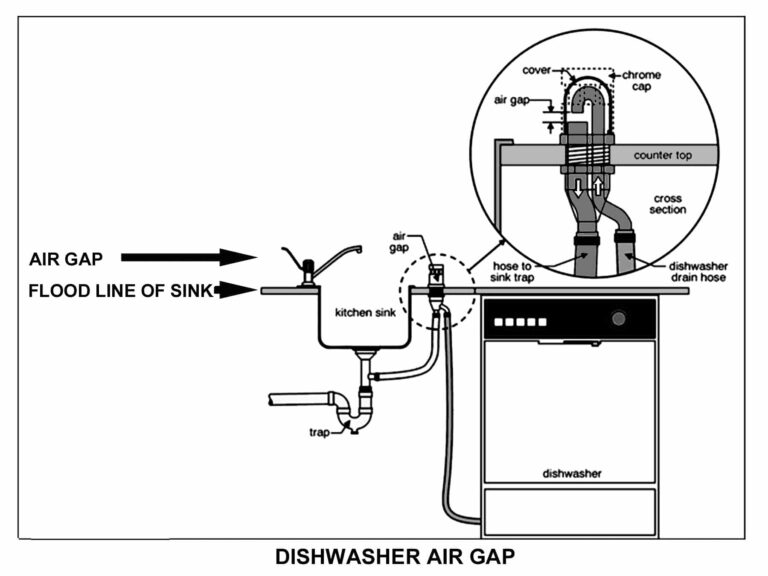

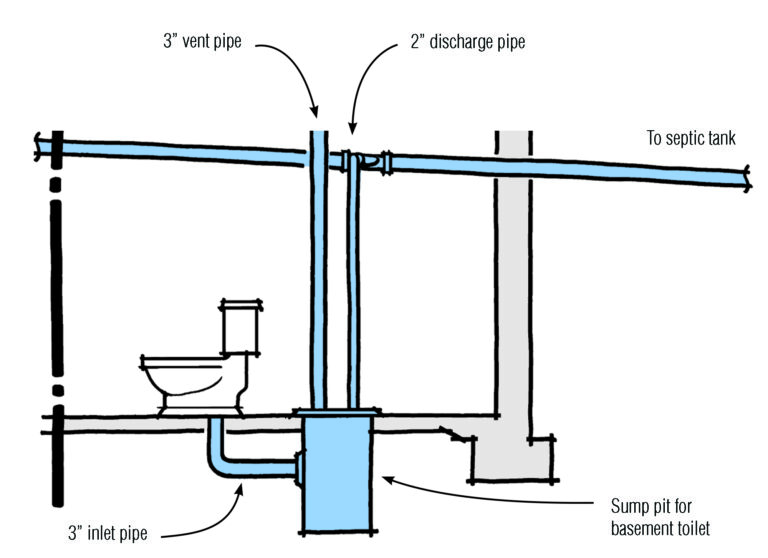

System piping is an essential component of any plumbing system. It involves the selection, installation, and maintenance of the pipes, fittings, valves, and other parts that make up the system. It is important to understand the components of system piping in order to ensure that the system runs efficiently and there are no leaks or other issues. The basic components of system piping include pipes, fittings, valves, traps, and other accessories. Pipe materials can include copper, steel, plastic, and a variety of other materials that are suitable for the application. Fittings are used to connect the pipe sections together and can include unions, couplings, elbows, tees, reducers, and others. Valves are used to control the flow and pressure of the water and can include stop valves, pressure reducing valves, check valves, and many others. Traps are used to prevent sewer gases from entering the system and can include cleanouts, P-traps, and other devices. Finally, other accessories can include expansion tanks, pressure gauges, hangers, and other components. Having a thorough understanding of system piping components is essential for any plumbing system installation.

Benefits of System Piping

System piping is a process of connecting multiple components within a system in order to improve efficiency and reduce costs. It is one of the most important aspects of any system, and its benefits can be tremendous. System piping can help to maximize the flow of liquids and gases, reduce energy consumption, reduce noise levels, and improve the safety and longevity of a system. It can also help to reduce the need for manual labor, which can result in cost savings. Additionally, system piping makes it possible to connect multiple components within a system, allowing for a greater range of options and possibilities. System piping is an important part of any system and can provide numerous benefits.

Installation and Maintenance of System Piping

System piping is an essential component of many industrial and commercial systems. It provides the means of transporting fluids and gases from one location to another, and is an important part of many maintenance and installation processes. Proper installation and maintenance of piping is critical to ensure the safety and reliability of a system. This includes following manufacturer instructions, proper sizing, and properly sealing and insulating all connections. Additionally, regular maintenance should be performed to ensure that the piping remains in good condition and all joints are properly sealed. This may involve cleaning, testing, and replacing components as needed. By following the correct installation and maintenance procedures, system piping can provide years of safe and reliable operation.

Types of System Piping

System piping is a crucial part of any industrial or commercial system, providing a safe and efficient means of transporting vital materials or fluids from one point to another. It consists of a network of pipes, valves, and other components that can be used to control the flow of liquids, gases, and other materials. System piping can come in a variety of materials and sizes, depending on the purpose of the project. Common types of system piping include copper, steel, stainless steel, polyethylene, PVC, and CPVC. Each type of material offers its own advantages and disadvantages, such as corrosion resistance, flexibility, and cost. No matter what type of system piping is used, proper installation and maintenance are essential for long-term performance and safety.

Applications of System Piping

System piping is a powerful tool used to create complex systems that can automate processes and provide efficient solutions. It can be used for a wide variety of applications, such as piping water, gas, oil, and other liquids and materials. It can also be used to create complex systems for industrial applications such as manufacturing, food processing, and construction. System piping can be used to construct pipelines, connecting different parts of the system to each other, and to control the flow of material through the system. It can also be used to control the pressure and temperature of the material, as well as the design of the system. System piping is an important part of modern engineering and construction, and can be used to create efficient, safe, and cost-effective solutions.

FAQs About the What Is A System Piping?

Q: What is a system piping?

A: System piping is a type of piping that is used for the circulation of water, air, or other fluids throughout a system, such as a building’s plumbing or HVAC system.

Q: What types of materials are used for system piping?

A: System piping is typically made of copper, PVC, or CPVC, although other materials such as galvanized steel and stainless steel can also be used.

Q: How is system piping installed?

A: System piping is typically installed by a professional plumber using the right tools and techniques. It is important to make sure that all the connections are secure and that the pipes are properly sealed to prevent leaks.

Conclusion

System piping is a complex yet important part of the industrial process. It involves the selection and installation of various pipes, fittings, and other components to ensure that liquids, gases, and other substances flow correctly throughout the system. System piping also requires proper maintenance to ensure that it is functioning properly. By understanding the various components of system piping, businesses and industrial facilities can ensure the safest and most efficient operations.