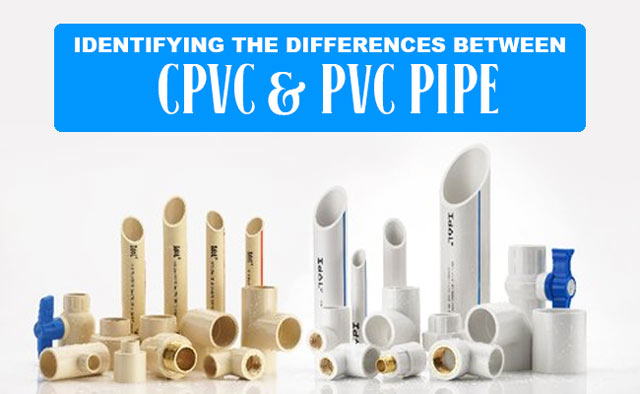

What Is CPVC Vs PVC?

CPVC (Chlorinated Polyvinyl Chloride) and PVC (Polyvinyl Chloride) are two of the most commonly used plastics in piping and plumbing applications. They are both thermoplastic materials that are easy to install and have a long lifespan. Both types of piping are resistant to corrosion and are used in a variety of applications. The primary difference between the two is that CPVC is more ductile and flexible than PVC and can withstand higher temperatures and pressures. CPVC is also more resistant to chemical attack than PVC and can be used in a wider range of applications.

Definition of CPVC and PVC

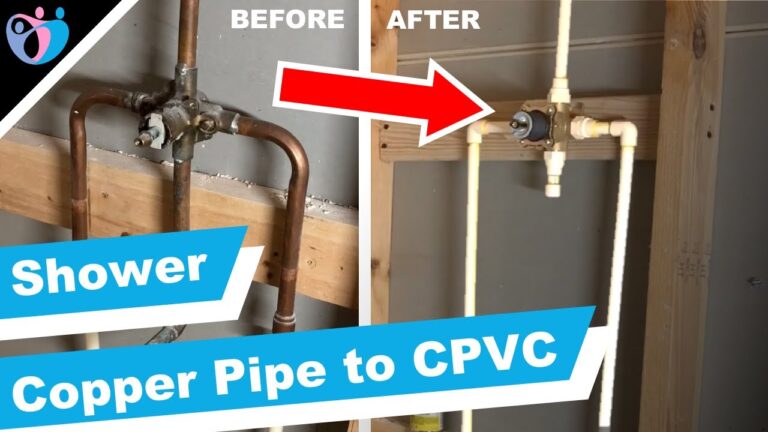

CPVC (chlorinated polyvinyl chloride) and PVC (polyvinyl chloride) are two different types of plastic piping often used for home plumbing systems. CPVC is a variation of PVC that has been chemically treated to increase its chlorine content. This makes CPVC more heat and chemical resistant than PVC, allowing it to be used in higher temperature applications, such as carrying hot and cold water. Both CPVC and PVC are available in a range of sizes and lengths, and both can be used in a variety of plumbing projects. CPVC is often used for hot water applications, while PVC is typically used for cold water applications.

Applications of CPVC and PVC

CPVC (Chlorinated Polyvinyl Chloride) and PVC (Polyvinyl Chloride) are both plastic materials used in a wide variety of applications. Both materials are tough, flexible, and resistant to corrosion and impact. CPVC is more heat-resistant than PVC, making it the preferred material for hot water pipes, and other applications that require higher temperature stability. PVC is widely used for cold water pipes, gutters, and other applications that require a more durable material. CPVC and PVC are also used in construction, manufacturing, and other industries. From roofing, siding, and windows to plumbing, electrical wiring, and window frames, CPVC and PVC can be used in a variety of applications.

Differences in Durability

Durability is a measure of how well a material or product can withstand wear and tear over time. While many materials and products may have similar features or functions, their durability can differ greatly. For example, a metal toolbox may be more durable than a plastic one, as it is more resistant to impacts and scratches. Similarly, a leather sofa may last longer than a fabric one as it is more resistant to stains and fading. Understanding the differences in durability can help you make the right decision when purchasing a product, making sure it will last.

Cost Differences between CPVC and PVC

CPVC (Chlorinated Polyvinyl Chloride) and PVC (Polyvinyl Chloride) are two of the most popular types of piping used for plumbing and other applications. Both types of piping are reliable and durable, but there are significant cost differences between the two materials. CPVC is generally more expensive than PVC, and the difference in cost can be as much as 25% or more. This is due to CPVC having a higher temperature tolerance, making it ideal for hot water applications. Additionally, CPVC requires a different type of cement and primer, which can add to the total cost. Ultimately, the decision of which piping material to use should be based on the application and the associated cost.

Benefits and Drawbacks of CPVC and PVC

CPVC (Chlorinated Polyvinyl Chloride) and PVC (Polyvinyl Chloride) are two types of plastic commonly used in plumbing and electrical conduit systems. Both have benefits and drawbacks that should be considered when deciding which material to use for a project. CPVC has the benefit of being highly durable and resistant to corrosion, and is suitable for hot and cold water applications. It is also more flexible than PVC, making it easier to work with. On the other hand, PVC is less expensive than CPVC, and is often used in home and industrial applications. It also has a higher fire resistance rating than CPVC, making it a better choice for electrical applications. Both materials have a long lifespan and are relatively easy to install, making them great options for many projects. However, CPVC and PVC each have their drawbacks – CPVC is more expensive than PVC, and PVC can be more difficult to work with. Ultimately, the best choice depends on the project, budget, and skill level of the installer.

Choosing the Right Material for Your Project

When it comes to completing a project, choosing the right material is essential for success. The material you select must be able to withstand the elements, be cost effective, and deliver the desired aesthetic. Whether you’re working on a residential or commercial project, careful consideration should be given to the material, as it will determine the overall longevity of the project. A few key factors to consider when selecting materials are: durability, cost, and aesthetic. Durability is essential, as the material will need to withstand wear and tear, as well as environmental conditions. Cost is also a factor, as some materials may be more expensive, but may offer more benefits in the long run. Lastly, the material should be aesthetically pleasing, as it will become a part of the overall look and feel of the project. With the right material, you can ensure that your project is a success.

FAQs About the What Is CPVC Vs PVC?

Q1. What is the difference between CPVC and PVC?

A1. The main difference between CPVC and PVC is that CPVC is more resistant to temperature fluctuations and has a higher maximum operating temperature than PVC. CPVC is also more resistant to chemicals, making it a better choice for applications where it may come into contact with certain chemicals.

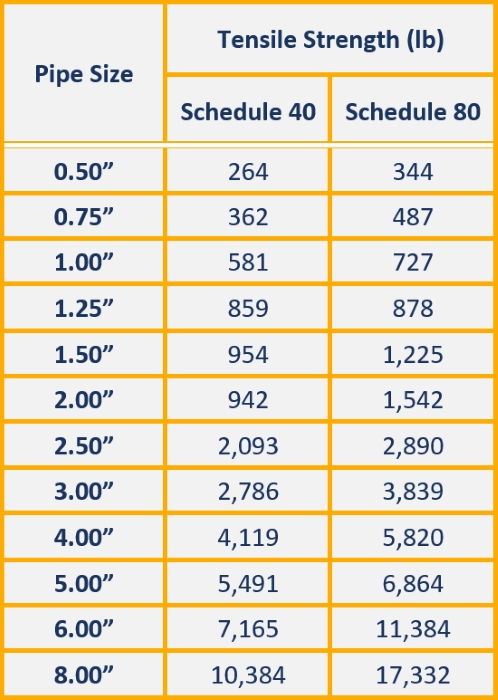

Q2. Is CPVC stronger than PVC?

A2. Yes, CPVC is stronger than PVC due to its enhanced chemical and temperature resistance. This makes it a better choice for applications that require greater strength or chemical resistance.

Q3. Can CPVC and PVC be used interchangeably?

A3. No, CPVC and PVC are not interchangeable and should not be used for the same application. If you’re unsure which material is best for your project, contact a professional for advice.

Conclusion

In conclusion, CPVC and PVC are both types of plastic piping used for plumbing applications. CPVC is generally more expensive than PVC, but it can withstand higher temperatures and pressures, making it the preferred material for hot water applications. PVC is less expensive and better suited for cold water applications, as it is not as strong as CPVC and can’t handle as much pressure. Both materials are long-lasting and durable, and can be used in a variety of plumbing applications.