What Is Piping Types?

Piping types refer to the different types of pipes used for various applications in construction, plumbing, and other industries. The most common types of pipes are galvanized steel, copper, and PVC, but there are other materials available as well. Each type of pipe has its own distinct characteristics and advantages, so it is important to understand the different options and select the best option for a specific application.

Overview of Piping Types

Piping is a structural system that allows fluids or gases to be transferred from one point to another. This system is composed of pipes, valves, and other components that work together to direct the flow of fluids. There are a variety of piping types available, each designed for specific applications. In this article, we will provide an overview of the different types of piping and their uses.

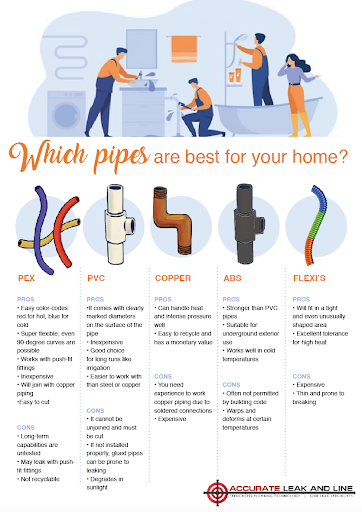

The most common types of piping include copper, PVC, CPVC, and PEX. Copper is the oldest type of piping, and is often used in residential and commercial applications. PVC, or polyvinyl chloride, is a popular choice for water and sewer applications due to its low cost and durability. CPVC, or chlorinated polyvinyl chloride, is a type of PVC that is resistant to corrosion and temperature changes. PEX, or cross-linked polyethylene, is a flexible plastic piping typically used for water supply lines.

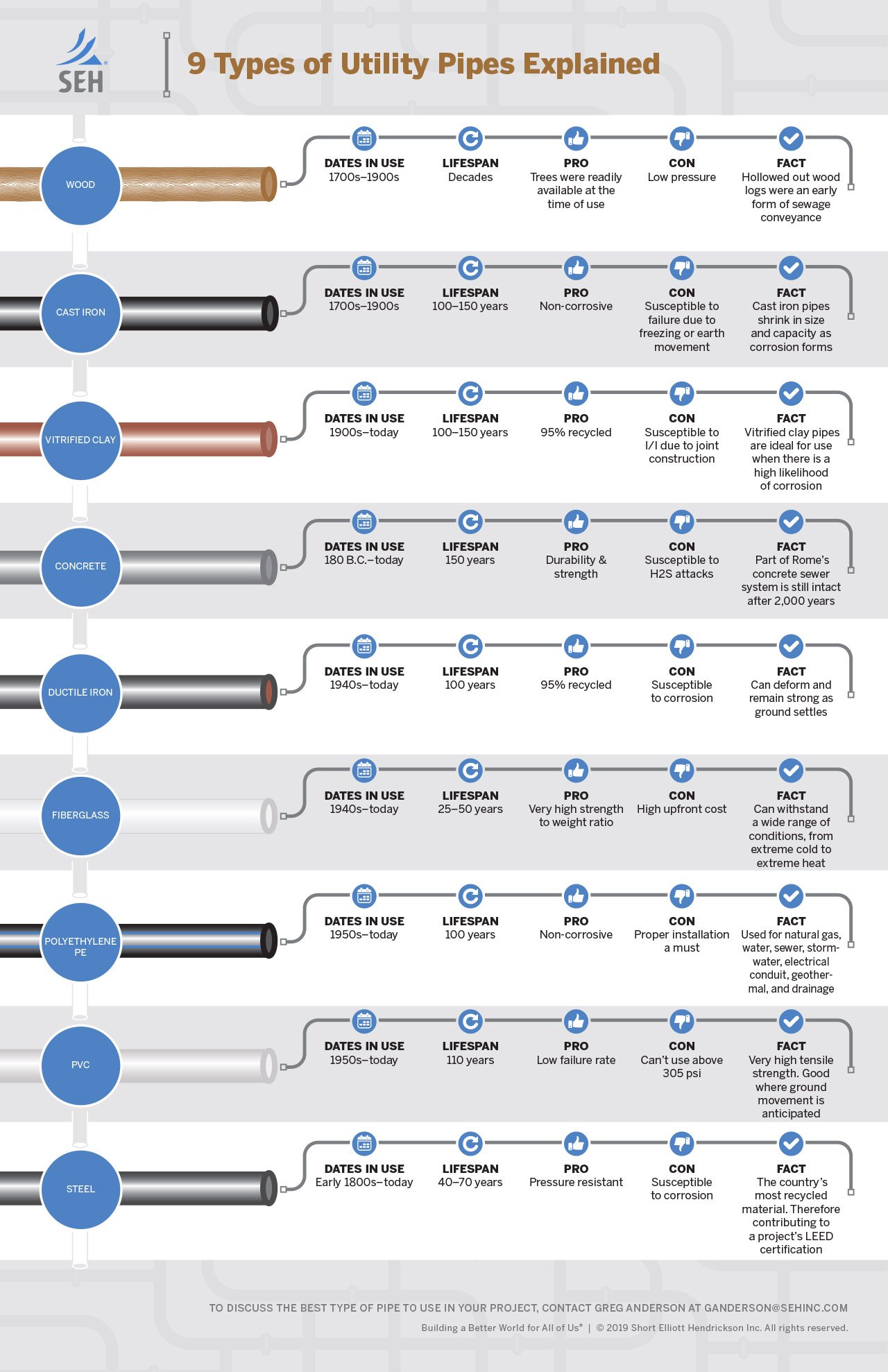

In addition to these common types of piping, there are also specialized piping systems designed for specific applications. For example, stainless steel piping is often used in food processing and chemical plants, while cast iron is often used for wastewater and drainage systems. High-density polyethylene (HDPE) is often used for fuel and oil lines, while polypropylene (PP) is used for medical applications.

No matter what type of piping is used, it is important to ensure that the system is properly installed and maintained to ensure safe and reliable operation. By understanding the different types of piping and their uses, you can make an informed decision when selecting the right piping system for your needs.

Types of Piping

Piping is an essential component of many industries, from water and gas distribution to plumbing and process engineering. It is important to understand the different types of piping available to ensure the best option is chosen for any given application. There are three main categories of piping: metal, plastic, and fiber. Each of these materials has its own unique advantages and disadvantages.

Metal piping is the most commonly used type due to its durability, strength, and cost-effectiveness. It can be used in a variety of applications, including water, gas, and steam. However, metal piping is prone to corrosion and can require regular maintenance.

Plastic piping is a popular alternative to metal piping due to its low cost and easy installation. It is often used in residential and commercial applications due to its flexibility and resistance to corrosion. However, plastic piping can be prone to cracking and leaking over time, and is not suitable for applications involving high temperatures.

Fiber piping is becoming increasingly popular due to its resistance to corrosion and ease of installation. It is often used in water and gas distribution systems due to its flexibility, durability, and lightweight. However, fiber piping is more expensive than metal or plastic and is not suitable for applications involving high temperatures.

No matter what type of piping is being used, it is important to choose the right material for the job. The right type of pipe can save time and money down the line, making it an essential part of any piping system.

Advantages of Piping

Piping is an essential component of any mechanical system. It is used to transport liquids, gases, and solid materials from one place to another. There are two main types of piping systems: threaded and unthreaded. Each type has its own advantages and disadvantages. Threaded piping is more commonly used than unthreaded piping because it is easier to connect and disconnect. Threaded piping also offers a better seal, which reduces the chance of leaks. Unthreaded piping, on the other hand, is more cost-effective and easier to repair. It is also less likely to corrode and is more resistant to vibration.

No matter what type of piping you choose, it is important to understand the advantages and disadvantages of each so you can make the best decision for your particular application. Threaded piping offers increased durability and a more secure connection, while unthreaded piping offers a lower cost and easier installation. It is important to consider the different types of piping and their advantages and disadvantages to make sure you select the right type for your application.

Design Considerations for Piping

Piping is an integral part of any industrial or commercial building, and the type of piping chosen will determine the efficiency and longevity of the piping system. Knowing the different types of piping available is essential to making the right choice for your project. In this blog, we discuss the different types of piping and the design considerations for each type.

Copper piping is one of the most popular and commonly used types of piping. It is a durable material that is resistant to corrosion and is relatively easy to install. Steel piping is also commonly used in industrial applications due to its durability and ability to withstand high temperatures. However, it is more expensive than copper and requires more specialized installation. PVC piping is the most affordable option, but it is not as durable as copper or steel and can easily be damaged by heat or chemicals.

Another type of piping is galvanized steel piping, which is coated with a layer of zinc to protect it from corrosion. It is more expensive than copper and steel, but it is also highly durable and resistant to corrosion. Polyethylene piping is also used in industrial applications and is highly resistant to chemicals and temperature changes.

It is important to consider the environment when choosing the right type of piping. Copper and steel are not suitable for areas with high humidity, while PVC piping is not suitable for areas with extreme temperatures. Additionally, some materials are not suitable for certain applications, such as food processing or medical applications.

When designing the piping system, it is important to consider the type of material, the type of connection, the size of the pipes, the pressure requirements, and the installation requirements. It is also important to consider the expected life span of the pipe and the cost of maintenance and repair. Taking all of these factors into consideration can help you choose the right type of piping for your project.

Installation and Maintenance of Piping

Piping systems are an integral part of many industrial, residential, and commercial applications. They are used for a variety of reasons, including transporting liquids, gases, and chemicals. However, their installation and maintenance require specialized knowledge and expertise. As such, understanding what piping types are available and how they differ is essential for any project.

The most common piping type is copper. Copper piping is widely used for both hot and cold water systems, and is considered to be one of the most reliable materials due to its durability and resistance to corrosion. Other types of piping include PVC, stainless steel, and PEX. Each has its own unique benefits and drawbacks, so it is important to research each type before making a decision.

In addition to the materials used, the type of piping system will also vary depending on the application. For example, a residential plumbing system may require a different type of piping than a commercial system. To ensure proper installation and maintenance of piping systems, it is important to hire a qualified technician. This will ensure that the system is installed correctly and is able to withstand the pressures and temperatures of the environment.

Understanding piping types and how they differ can help ensure that any project is properly installed and maintained. While the materials used are important, the type of piping system and the expertise of the technician are also important for the success of any project. With the right knowledge and expertise, piping systems can be installed and maintained safely and effectively.

FAQs About the What Is Piping Types?

Q1: What are the different types of piping?

A1: The most common types of piping are metal, plastic, and fiberglass. Metal piping is typically used in industrial settings for larger pipes, while plastic is used for smaller pipes in residential settings. Fiberglass is also used for large pipes in certain industrial settings.

Q2: What are the advantages and disadvantages of each type of piping?

A2: Metal piping is strong and durable, but it can corrode over time. Plastic piping is lightweight and easy to install, but it can be prone to cracking and leaking. Fiberglass is resistant to corrosion, but it can be brittle and difficult to work with.

Q3: What factors should be considered when selecting a piping type?

A3: Factors such as cost, durability, ease of installation, and the environment in which the piping will be used should be considered when selecting a piping type. Additionally, the type of fluid that will be running through the piping and the size of pipe needed should also be taken into account.

Conclusion

Piping types is a broad term used to describe the different types of pipes used in a variety of applications. Different types of pipes are used depending on the application, including materials, diameter, and pressure requirements. Knowing what type of pipe is appropriate for a specific application is important for a successful installation. This will ensure that the pipe can withstand the conditions and pressures required for the specific application.