What Is Pressure Pipe?

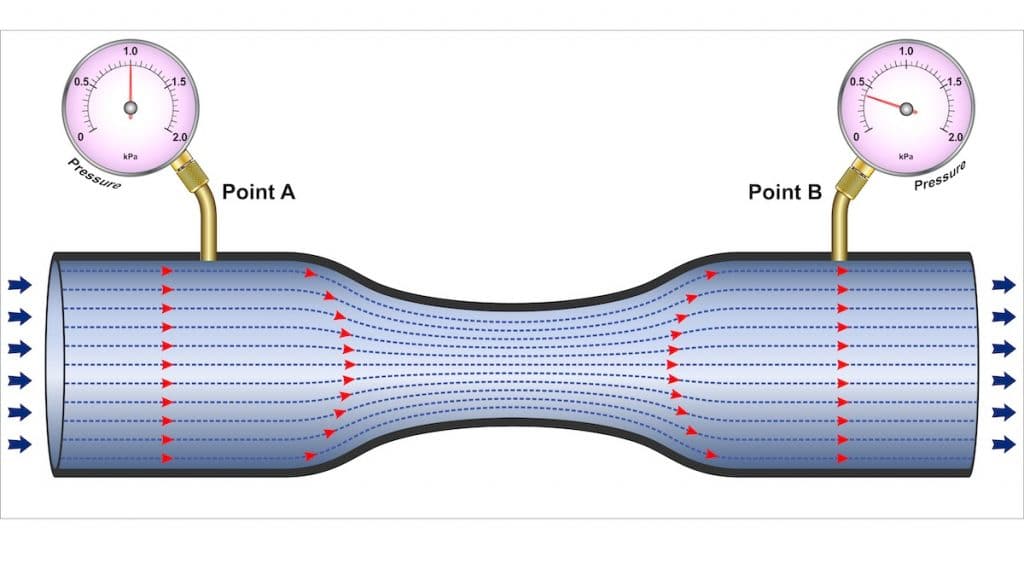

Pressure pipes are pipes used in the transportation of liquids or gases, such as water, oil, and natural gas. They are used in both residential and commercial applications and are designed to withstand the pressure from these substances. Pressure pipes come in a variety of materials including plastic, steel, and concrete and are available in a range of sizes and weights. Pressure pipes are designed to maintain a constant pressure and flow of fluids or gases and are used in applications such as water supply, sewage, and industrial processes.

Definition of Pressure Pipe

Pressure pipe is a type of piping system used to transport fluids at high pressures. It is designed to withstand the internal pressure generated by the fluid being transported, as well as the external pressure exerted on the pipe from the environment. Pressure pipes can be made of a variety of materials, including metal, plastic, and concrete. Each type of pressure pipe has its own advantages and disadvantages. Metal pipes are the most durable and are often used in commercial and industrial applications, while plastic pipes are more economical and lightweight. Concrete pressure pipes are used in high-pressure applications such as water mains and wastewater systems. Pressure pipes must be designed to meet specific safety and performance requirements, as well as local and national codes. Pressure pipe installations require careful design and installation to ensure that they are safe and reliable.

Types of Pressure Pipe

Pressure pipe is a type of piping system that is used to maintain a steady pressure within a system. While different types of pressure pipe exist, the most common types are PVC, CPVC, PEX, Polyethylene, and Copper.

PVC or Polyvinyl Chloride pipe is one of the most commonly used types of pressure pipe. It is highly durable and resistant to corrosion, making it an ideal choice for plumbing, irrigation, and drainage applications. This type of pipe is also relatively inexpensive and easy to install.

CPVC or Chlorinated Polyvinyl Chloride pipe is an improved version of PVC pipe. It has a higher temperature and pressure tolerance than PVC, making it a great choice for applications that require higher temperatures and pressures. It is also more expensive than PVC pipe.

PEX or Cross-linked Polyethylene pipe is a type of plastic pipe that is made of polyethylene. It is highly flexible and can be used for hot or cold water systems, radiant heating systems, and some industrial applications. PEX has excellent resistance to corrosion and is easy to install.

Polyethylene pipe is a type of plastic pipe that is made of polyethylene. It is a highly flexible and corrosion-resistant material that is used in a variety of applications, such as water and wastewater systems, gas distribution systems, and industrial piping systems.

Finally, copper pipe is one of the oldest and most commonly used types of pressure pipe. It is highly corrosion-resistant and has a long service life. Copper pipe is often used in water systems, gas systems, and industrial applications. It is also one of the most expensive types of pressure pipe.

Therefore, when it comes to choosing the right pressure pipe for your system, there are several different types to consider. It is important to choose the right type of pipe for your application to ensure it is durable and reliable.

Advantages of Pressure Pipe

Pressure pipes are a type of piping system that is typically used in industrial applications. They are designed to withstand extreme pressures, making them ideal for transporting a variety of liquids and gases. Pressure pipes are incredibly versatile and offer many benefits for a wide range of applications.

One of the main advantages of pressure pipes is their durability. Pressure pipes are constructed from robust materials like stainless steel or carbon steel, making them highly resistant to corrosion and wear. Additionally, they are available in different sizes and wall thickness, allowing them to be tailored to specific pressure ratings.

Another benefit of pressure pipes is their ease of installation. Pressure pipes are ideally suited for welding and can be easily assembled with minimal effort and cost. This makes them ideal for construction projects that require quick completion.

Pressure pipes are also highly efficient and cost-effective. With a high-pressure rating and low friction, pressure pipes can reduce the energy costs associated with transporting liquids or gases. Additionally, pressure pipes are lightweight and flexible, reducing the demands on the overall installation.

Finally, pressure pipes are incredibly safe. They have been designed to operate in extreme conditions and they are tested rigorously to ensure their safety. This makes them an ideal choice for applications that require a reliable and safe piping system.

In summary, pressure pipes offer a wide range of benefits for a variety of applications. They are incredibly durable, easy to install, efficient, cost-effective, and safe. Pressure pipes are a great choice for any project that requires a reliable and efficient piping system.

Installation Methods for Pressure Pipe

Pressure pipe is a type of piping used to transport liquids, gases, and slurries under high pressure. Different installation methods are used depending on the type and application of the pipe. Understanding the various installation methods for pressure pipe is key to ensure the pipe is installed correctly and safely.

One of the most common installation methods for pressure pipe is trenching. This method involves digging a trench deep enough for the pipe and then laying it in the trench. The trench is then filled in and the pipe is connected to the necessary fittings. This method is used when the pipe needs to be installed close to the ground and away from any structures.

Another installation method for pressure pipe is directional drilling. This method is used when the pipe needs to be placed in an area with limited access. A drilling machine is used to bore holes in the ground and the pipe is then pulled through the holes. This method is less disruptive to the surrounding environment and can be used for longer distances than trenching.

Pressure pipe can also be installed using jacking and boring. This method is used when the pipe needs to be installed through a wall or other hard surface. The pipe is attached to a jacking machine which makes a hole in the wall and then pulls the pipe through. This method is often used for pipe installation in urban areas where trenching is not possible.

Knowing the various installation methods for pressure pipe is key to ensure the pipe is installed correctly and safely. It is important to select the right method for the specific application to ensure the pipe is installed correctly and meets the necessary safety standards.

Maintenance of Pressure Pipe

Pressure pipes are an integral part of many industrial and commercial operations. Pressure pipes are used for various applications, such as water supply, sewage, and waste disposal. Therefore, it is important to ensure that they are properly maintained. This article will provide an in-depth analysis of the maintenance of pressure pipes and their importance.

Regular inspections and maintenance of pressure pipes are essential for ensuring that they remain safe and functional. Regular inspections can identify any potential problems such as blocked pipes, corrosion, and leakages. The maintenance process also includes cleaning, flushing, and examining the pipes for any signs of wear and tear. Additionally, pressure pipes need to be regularly tested for their pressure rating to make sure that they are suitable for the application.

In order to ensure that pressure pipes remain in good condition, it is important to use the right materials and adhere to the manufacturer’s specifications. Furthermore, it is important to regularly check the pipes for any signs of damage or leaks. It is also important to perform regular maintenance to prevent the buildup of debris, which can lead to blockages. Finally, it is essential to ensure that the pressure pipes are adequately supported and secured in order to prevent them from becoming damaged or dislodged.

By following the above-mentioned maintenance protocols, pressure pipes can be kept in good condition, ensuring that they remain safe and functional. Pressure pipes are an important component of many industrial and commercial operations, and proper maintenance is essential for their long-term operation.

Troubleshooting Common Issues with Pressure Pipe

Pressure pipes are a common type of plumbing pipe used in homes and buildings to transport water and other liquids. They are designed to withstand pressure from the water inside, and are made of various materials such as PVC, copper, or steel. While pressure pipes are generally reliable and durable, they can experience problems over time due to corrosion, leaks, or blockages. It’s important to be aware of the potential issues that can arise with pressure pipes so you can take the necessary steps to fix them.

Common problems with pressure pipes include corrosion, leaks, and blockages. Corrosion can occur when the pipes are exposed to certain chemicals or elements, such as chlorine or salt. If left untreated, this can lead to leaks and other damage. Leaks can happen due to a variety of reasons, including loose fittings, old pipes, or cracks in the pipes. Blockages can occur when foreign objects get stuck in the pipes, causing a buildup of water that can lead to a burst pipe.

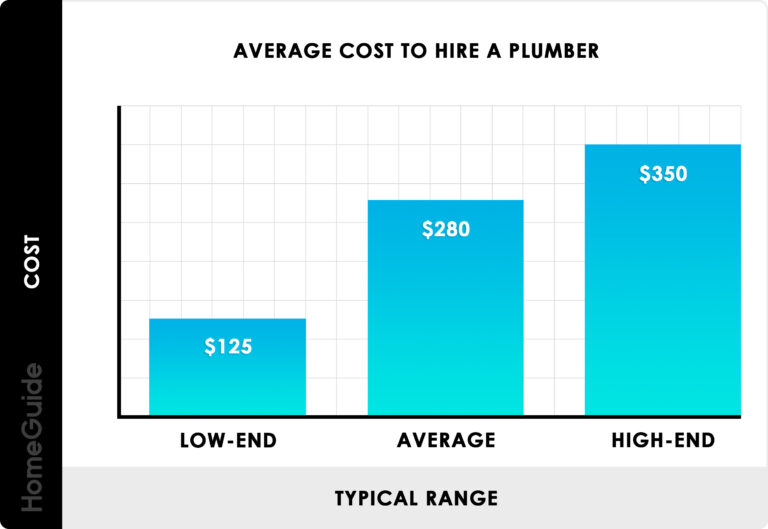

To troubleshoot these types of issues, it’s important to inspect the pipes for any signs of corrosion, leaks, or blockages. If you spot any of these problems, you should contact a professional plumber to assess the issue and determine the best course of action. It’s also important to regularly maintain your pressure pipes by checking for any signs of damage or wear and tear, and replacing any worn parts. Doing so can help you avoid costly repairs in the future.

FAQs About the What Is Pressure Pipe?

1.Q: What materials are used to make pressure pipe?

A: Pressure pipe is typically made from a variety of materials, including steel, copper, plastic, and brass.

2.Q: What are the different types of pressure pipe?

A: The different types of pressure pipe include black steel, galvanized steel, PVC, and copper.

3.Q: What is the difference between a pressure pipe and a regular pipe?

A: Pressure pipe is designed to withstand higher pressure than a regular pipe and is typically thicker and stronger.

Conclusion

Overall, pressure pipes are an important and essential part of many plumbing systems. They are made of a variety of materials, including plastics, metals, and concrete, and come in different sizes, shapes, and lengths. Pressure pipes are used in a variety of applications, including water supply, irrigation, drainage, and sewage. They are durable, reliable, and provide a safe, efficient way to move liquids from one place to another.