What is PVC pipe grade?

Understanding PVC Pipe Grades

PVC pipe grade – a term widely used in the world of construction and plumbing. But what exactly does it mean? PVC, short for polyvinyl chloride, is a versatile and economical material used in various applications. In the context of pipes, PVC pipe grade refers to the quality and specifications of the PVC used in manufacturing pipes.

PVC pipe grade plays a crucial role in determining the performance and durability of pipes. Different grades of PVC vary in terms of their strength, durability, chemical resistance, and temperature tolerance. Higher-grade PVC pipes typically offer superior performance and longevity, making them suitable for demanding applications.

Importance of PVC Pipe Grade in Various Applications

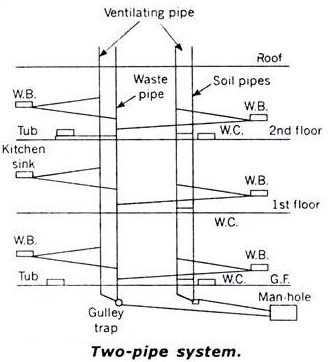

PVC pipes are used in a wide range of applications, from residential plumbing systems to large-scale industrial projects. Understanding PVC pipe grade is essential for ensuring that the pipes you choose will meet the specific requirements of your project.

For residential plumbing systems, PVC pipes of lower grades may be sufficient, as they are typically subjected to lower pressure and temperature. However, for commercial buildings or industrial applications where the pipes may be exposed to higher pressures, extreme temperatures, or corrosive chemicals, it is important to select PVC pipes of a higher grade to ensure their reliability and longevity.

Additionally, the use of the correct PVC pipe grade can help prevent leaks, burst pipes, and other plumbing issues that can result in costly repairs and disruptions. By choosing the right PVC pipe grade for your specific needs, you can save time, money, and headaches down the line.

Different Types of PVC Pipe Grades

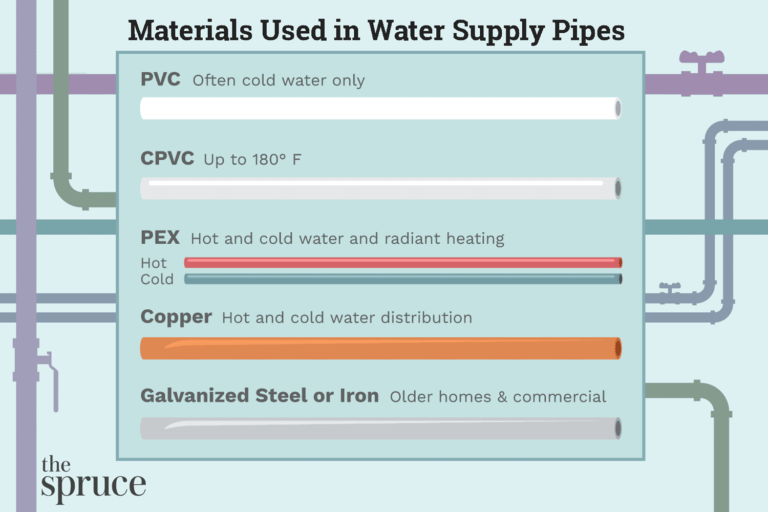

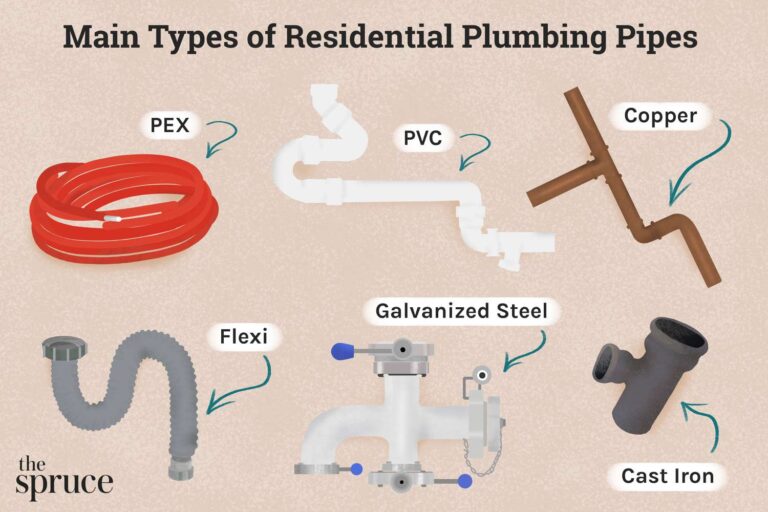

There are several different types of PVC pipe grades available in the market. These grades are categorized based on their specific properties and intended applications. Some of the most common PVC pipe grades include:

- Schedule 40: This is the most common PVC pipe grade used in residential plumbing systems. It is known for its excellent strength, durability, and affordability. Schedule 40 PVC pipes are suitable for a wide range of applications, including water supply, drainage, and irrigation.

- Schedule 80: Schedule 80 PVC pipes are designed to withstand higher pressure and temperature compared to Schedule 40 pipes. They are commonly used in industrial applications, such as chemical processing plants and refineries, where pipes are exposed to harsh environments and demanding conditions.

- DWV: DWV stands for Drain Waste Vent, and it is a specific PVC pipe grade designed for non-pressure applications. DWV pipes are commonly used in plumbing systems to carry wastewater and vent gases out of buildings. They are not suitable for carrying potable water or other pressurized fluids.

- CPVC: CPVC, or Chlorinated Polyvinyl Chloride, is a specialized PVC pipe grade that is resistant to higher temperatures and more chemically resistant than regular PVC. CPVC pipes are often used in hot water supply systems, as well as industrial applications where the pipes are exposed to corrosive chemicals.

Differences Between PVC Pipe Grades and Their Uses

The different PVC pipe grades vary in terms of their pressure ratings, temperature tolerances, chemical resistance, and other properties. Understanding these differences is crucial for selecting the right grade for your specific application.

For example, Schedule 40 PVC pipes have a pressure rating of 120 psi, while Schedule 80 pipes have a higher pressure rating of 200 psi. This makes Schedule 80 pipes more suitable for applications that require higher pressure resistance, such as industrial piping systems.

Similarly, CPVC pipes have a higher temperature tolerance compared to regular PVC pipes. While regular PVC pipes can handle temperatures up to 140°F, CPVC pipes can withstand temperatures up to 200°F. This makes CPVC pipes ideal for hot water supply systems.

It’s important to note that using the wrong PVC pipe grade for a specific application can lead to premature failure, leaks, and other issues. Therefore, it’s essential to consult with a knowledgeable professional or refer to the manufacturer’s guidelines to ensure you choose the right PVC pipe grade for your project.

How to Identify PVC Pipe Grade Markings

Identifying the PVC pipe grade markings is crucial for determining the properties and specifications of the pipes. PVC pipes are typically marked with information such as the manufacturer’s name, pipe size, pressure rating, temperature rating, and material type.

The markings can be found on the surface of the pipe and are usually imprinted or embossed. The specific markings may vary depending on the PVC pipe grade and the manufacturer. It’s important to refer to the manufacturer’s guidelines or consult with a professional if you have any doubts about the markings or specifications of the pipes.

Factors to Consider When Choosing PVC Pipe Grade

When selecting the right PVC pipe grade for your project, there are several factors to consider:

- Application: Determine the specific requirements of your application, including the pressure, temperature, and chemical resistance needed. This will help you narrow down the suitable PVC pipe grades for your project.

- Standards and certifications: Look for PVC pipe grades that meet industry standards and have relevant certifications. This ensures that the pipes have been tested and approved for their intended applications.

- Cost: Consider the cost of the PVC pipe grade and balance it with the performance and durability required for your project. While higher-grade PVC pipes may cost more initially, they can offer long-term savings by reducing the risk of failures and repairs.

- Compatibility: Ensure that the selected PVC pipe grade is compatible with other materials or systems that will be connected to the pipes. Compatibility issues can lead to leaks or other problems down the line.

By carefully considering these factors and consulting with experts when needed, you can make an informed decision and choose the right PVC pipe grade for your specific needs.

Common Misconceptions About PVC Pipe Grades

There are several misconceptions surrounding PVC pipe grades that are important to address:

- All PVC pipes are the same: This is not true. PVC pipes come in different grades, each with its own set of properties and specifications. Choosing the right grade is crucial for ensuring optimal performance and longevity.

- Higher-grade PVC pipes are always better: While higher-grade PVC pipes may offer superior performance and durability, they may not always be necessary for every application. It’s important to consider the specific requirements of your project and choose the right grade accordingly.

- PVC pipes are not suitable for all applications: PVC pipes are versatile and can be used in a wide range of applications. However, it’s important to select the appropriate PVC pipe grade that meets the requirements of your specific application.

PVC Pipe Grade Standards and Certifications

To ensure the quality and performance of PVC pipes, various industry standards and certifications have been established. These standards provide guidelines for the manufacturing, testing, and performance of PVC pipes.

Some of the commonly recognized PVC pipe standards include ASTM D1785 for pressure pipes, ASTM D2665 for DWV pipes, and ASTM F441/F442 for CPVC pipes. These standards specify the requirements for PVC pipe dimensions, pressure ratings, temperature tolerances, and other properties.

In addition to industry standards, there are also certifications such as NSF/ANSI 61 for drinking water systems and NSF/ANSI 14 for plastic piping systems. These certifications ensure that the PVC pipes meet specific health and safety requirements.

It is important to look for PVC pipes that comply with the relevant standards and hold the necessary certifications to ensure their quality and suitability for your application.

FAQS for What is PVC pipe grade?

1. What is PVC pipe grade?

PVC pipe grade refers to a specific type of polyvinyl chloride (PVC) material that is designed and manufactured to meet the specific requirements and standards for use in piping systems. This material is formulated to provide the necessary properties for plumbing, irrigation, and various other applications.

2. What are the key properties of PVC pipe grade material?

PVC pipe grade material is known for its excellent chemical resistance, durability, low cost, and ease of installation. It is also non-corrosive, lightweight, and has a smooth interior surface that minimizes friction and scale buildup.

3. How is PVC pipe grade different from other types of PVC?

PVC pipe grade is formulated to meet stringent standards for use in pressurized piping systems, and it has specific additives and properties that distinguish it from other types of PVC, such as those used for vinyl flooring or electrical insulation.

Conclusion

Choosing the Right PVC Pipe Grade for Your Needs Selecting the right PVC pipe grade for your project is essential for ensuring optimal performance, durability, and reliability. PVC pipes come in different grades, each with its own set of properties and specifications.

By understanding the requirements of your application, considering the specific properties of each PVC pipe grade, and consulting with experts when needed, you can make an informed decision and choose the right PVC pipe grade for your specific needs.

Remember to look for PVC pipes that meet industry standards and hold relevant certifications to ensure their quality and suitability. By taking the time to select the right PVC pipe grade, you can avoid costly repairs, prevent leaks, and ensure the long-term success of your project.