What Is PVC Polymer?

PVC (polyvinyl chloride) polymer is a type of plastic that is made up of repeating units of vinyl chloride. It is one of the most commonly used plastics in the world, and is used for a wide variety of applications due to its low cost, durability, and chemical resistance. PVC is commonly used in the construction industry for pipes, flooring, window frames, and more. It is also used in the medical industry for blood bags, IV bags, and other medical products. In addition, it is used in the automotive and textile industries for various products. PVC is a versatile material that is used in a variety of industries and applications.

Overview of PVC Polymer

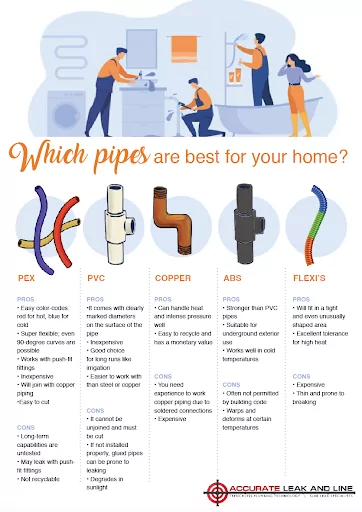

PVC (polyvinyl chloride) is a versatile, thermoplastic polymer with a wide range of uses. It is one of the most commonly used plastics in the world, with over 50,000 industrial and consumer products made from it. PVC has been around for more than a century, but it wasn’t until the early 1950s that it began to be widely used as a building material. PVC is a strong, rigid material that is resistant to corrosion, weathering, and abrasion, making it an ideal choice for a variety of applications, from plumbing to electrical wiring. PVC is also relatively low-cost and easy to work with, making it an attractive choice for DIY projects. PVC is recyclable and can be used in a variety of ways, from piping to furniture. PVC is often used for window frames, siding, and insulation. PVC is also used in a wide range of industrial applications, such as medical devices, automotive parts, and packaging. PVC is a safe, durable, and versatile material that has revolutionized the way we build and use products.

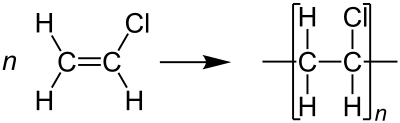

Chemical Structure of PVC Polymer

PVC, or polyvinyl chloride, is an incredibly useful synthetic polymer that can be found in a wide variety of consumer products. It is a thermoplastic material that is strong, durable, and highly resistant to corrosion, making it a great material for a variety of applications. But what exactly is PVC and how is it made?

PVC is a polymer made up of repeating units of vinyl chloride monomers. These monomers are linked together through a process known as polymerization, where the vinyl chloride molecules are broken down and then reassembled. This process is also used to create other polymers such as polystyrene and polyethylene. PVC is a thermoplastic material, meaning it can be melted and reshaped many times before it loses its structural integrity. This makes it a great material for creating objects with intricate shapes and designs.

The chemical structure of PVC is very complex, and it is composed of several different elements. It has a unique molecular structure that allows it to be stable, durable, and resistant to wear and tear. The physical properties of PVC are determined by the amount of chlorine present in the polymer. The higher the chlorine content, the more rigid and strong the polymer will be.

PVC has become an increasingly popular material for a variety of applications due to its strength, durability, and corrosion resistance. From plumbing systems to medical equipment, PVC is a versatile and reliable material that is sure to continue to be a staple in the construction and manufacturing industries.

Advantages of PVC Polymer

PVC Polymer, or Polyvinyl Chloride, is a versatile and cost-effective type of plastic used for a variety of applications. It’s a durable and lightweight material that has a number of advantages over traditional materials. It’s strong, fire-resistant, and resistant to corrosion and rust. PVC is also much more affordable than other plastics, making it a great choice for a range of projects.

One of the major advantages of PVC Polymer is its flexibility. It can be molded into a variety of shapes and sizes, making it an ideal material for a wide range of applications. It’s also resistant to weathering and can withstand high temperatures, making it a great choice for outdoor projects. PVC is also easy to clean and maintain, making it a great choice for a variety of indoor and outdoor projects.

PVC Polymer is also non-toxic and safe to use in a variety of projects. It’s also recyclable, making it an environmentally friendly material. Additionally, PVC Polymer is much more affordable than other types of plastic, making it a great choice for projects on a budget.

Overall, PVC Polymer is a great choice for a variety of projects due to its affordability, flexibility, and durability. It’s a great choice for projects that require strong and fire-resistant materials, and its recyclability makes it an eco-friendly choice. With its versatility and affordability, PVC Polymer is an ideal choice for a variety of projects.

Disadvantages of PVC Polymer

PVC polymer, or polyvinyl chloride, is a durable plastic that has a wide range of applications, from medical products to construction materials. However, this plastic has some drawbacks that can’t be overlooked. To make an informed decision about its use, it’s important to understand the potential risks of PVC polymer.

One of the main disadvantages of PVC polymer is its potential for environmental damage. PVC is made of chlorine, which is a hazardous substance. When PVC is burned, it releases toxic chemicals into the air, which can cause respiratory issues and other health problems. Additionally, it can leach out toxic chemicals into the ground when disposed of improperly.

Another disadvantage of PVC is its cost. PVC is more expensive than other plastics, making it cost-prohibitive for some applications. It also requires special tools and skills to work with, so labor costs are higher.

Finally, PVC is not as durable as other plastics, so it may not stand up to wear and tear over time. It’s also hard to recycle, leading to more waste.

When considering the use of PVC polymer, it’s important to weigh these potential drawbacks against the benefits. Be sure to assess the potential environmental and health risks, as well as the cost and durability of the product. With careful consideration, you can make an informed decision about the use of PVC polymer.

Applications of PVC Polymer

Polyvinyl Chloride (PVC) Polymer is a versatile and widely used polymer, found in a variety of applications due to its strong chemical and mechanical properties. It is primarily used in construction, electrical/electronic industries, and automotive applications. PVC Polymer is also found in medical devices, packaging materials, and consumer products like toys and furniture.

PVC Polymer is highly durable and can withstand most environments, making it a great choice for outdoor applications. It is also resistant to UV radiation, making it an ideal choice for window and door frames, as well as other exterior components. PVC Polymer is also highly resistant to corrosion, making it suitable for use in piping systems and plumbing fixtures.

Additionally, PVC Polymer is also flame retardant, making it an ideal choice for fire doors and other fire-resistant applications. It also has excellent electrical insulation properties, making it a great choice for electrical wiring and other electrical components. Finally, PVC Polymer is also non-toxic, making it an ideal choice for food packaging and medical products.

In conclusion, PVC Polymer is a popular and versatile polymer with a variety of applications due to its strong chemical and mechanical properties. It is highly durable, resistant to UV radiation, corrosion, and flame, and is also non-toxic, making it a great choice for a variety of applications.

Environmental Impact of PVC Polymer

PVC (Polyvinyl Chloride) is a type of plastic polymer used in construction, automotive, and other industries. It is a versatile material that is inexpensive, lightweight, and durable. But is it environmentally friendly? The answer to this question depends on how it is manufactured and used.

When it comes to production, PVC requires energy-intensive manufacturing processes that release hazardous substances, including chlorine, into the environment. The production of PVC also produces VOCs (Volatile Organic Compounds), which can contribute to the formation of smog and ground-level ozone.

When PVC products are incinerated, they release hazardous chemicals, including dioxins, furans, and heavy metals, into the atmosphere, making them potentially dangerous to human health and the environment.

On the other hand, PVC products are recyclable and can be recycled into new PVC products. However, the recycling process is costly and requires specialized equipment, meaning that most recycled PVC is used in the production of products such as flooring and roofing materials.

Overall, the environmental impact of PVC polymer depends on how it is manufactured, used, and disposed of. It is important to consider the environmental consequences of PVC production and use before making any decisions.

FAQs About the What Is PVC Polymer?

Q1. What is the difference between PVC and other plastics?

A1. PVC, or polyvinyl chloride, is a type of plastic that is unique in its composition and properties. PVC is a thermoplastic and, unlike other plastics, it remains solid when heated. It is also highly resistant to weather and chemicals, making it a popular choice for construction materials.

Q2. What are the common uses of PVC?

A2. PVC is often used for window frames, pipes, and vinyl siding. It is also used to make furniture, flooring, and electrical insulation. PVC is also used in medical equipment and for packaging.

Q3. Is PVC recyclable?

A3. Yes, PVC is recyclable, although it is not as widely recycled as other plastics due to its unique composition. Some PVC products, such as pipes, can be recycled into new products.

Conclusion

PVC polymer is a versatile thermoplastic material with a wide range of applications. It is a strong, resilient material that is resistant to corrosion and fire, and is also very easy to fabricate. PVC polymer is an economical and sustainable choice for a variety of applications, from plumbing to flooring to furniture, and more. With its unique properties and versatility, PVC polymer is an ideal material for a variety of products and projects.