What Is The Formula For PVC?

PVC (Polyvinyl Chloride) is an important thermoplastic material used in a wide range of applications. It is a durable and versatile material that can be used in the production of pipes, furniture, windows and doors, flooring, and many other items. The formula for PVC is (C2H3Cl)n, where n is the number of monomers in the polymer chain. The PVC molecules are formed by the combination of chlorine atoms with two carbon atoms and three hydrogen atoms, which are then linked together to form a chain.

What is PVC?

PVC (polyvinyl chloride) is a thermoplastic polymer that is widely used in the construction industry due to its excellent durability and superior resistance to water, chemicals, and heat. It is also commonly used to make pipes, window frames, flooring, and insulation. PVC is created from a combination of several chemicals, including chlorine, ethylene, and vinyl chloride. The formula for PVC varies depending on the desired properties and applications.

In general, the PVC formula is composed of a base polymer, a plasticizer, and a stabilizer. The base polymer is a combination of polyvinyl chloride resins and fillers, while the plasticizer is used to make the material soft and flexible. The stabilizer is then added to provide temperature and UV resistance, as well as flame retardancy. Depending on the application, additional chemicals may be added to enhance the properties of the PVC.

PVC is an incredibly versatile material that can be used for a wide range of applications. Its superior durability and resistance to water and heat make it an excellent choice for a variety of products, from pipes and window frames to flooring and insulation. Understanding the formula for PVC is essential to selecting the right material for a particular application.

What Materials are Used to Create PVC?

Polyvinyl Chloride (PVC) is a sturdy, durable plastic material that is commonly used in many different industries. The formula for PVC is a combination of three components: polyvinyl chloride, plasticizers, and stabilizers. These components work together to give PVC its unique properties. Polyvinyl chloride is the main component, and is made up of chlorine and ethylene. Plasticizers are added to improve the flexibility and durability of the material and are typically made up of phthalates, adipates, and trimellitates. Stabilizers are added to improve the stability of the material and typically include metal soaps and organic tin compounds. All of these components combined create a strong and versatile plastic material that is used for a variety of applications.

What is the Chemical Composition of PVC?

PVC, polyvinyl chloride, is an incredibly versatile and common thermoplastic used for a vast array of applications. PVC is a chemically resistant, hard material that is strong and durable. But, what exactly is the formula for PVC?

The chemical composition of PVC is composed of a vinyl chloride monomer, or VCM. The VCM is then combined with a catalyst and other agents. The catalyst helps to form the rigid, strong material that we know as PVC. The other compounds that are added to the mixture can include stabilizers, lubricants, plasticizers, and pigments. These additional ingredients can be used to create a wide range of products with different properties, such as increased flexibility, weather-resistance, and flame-retardant properties.

PVC is an incredibly popular material due to its strength and versatility. It is used to make pipes, tubes, and fittings for plumbing, as well as flooring, insulation, window frames, and roofing membranes. PVC is also widely used in the automotive and aerospace industries for its light weight and resistance to chemicals and heat.

Understanding the formula for PVC is important for manufacturers and other professionals so that they can select the right materials for the job. The combination of VCM, catalyst, and other additives gives PVC the unique characteristics that make it an ideal choice for many applications.

How is PVC Formed?

Polyvinyl Chloride, more commonly known as PVC, is a versatile polymer used in a wide array of applications across a variety of industries. It is formed when a combination of vinyl chloride monomer (VCM) and other additives are heated and mixed together. The most common additives used in the formation of PVC are stabilizers, lubricants, and plasticizers. When heated and mixed, these ingredients form a molten plastic that is then cooled and formed into the desired shape. The resulting material is a strong and durable material with excellent corrosion and water resistance. It is also lightweight and cost-effective, making it a popular choice for a variety of projects. PVC is used to create everything from pipes and fittings to window frames and decking material. Its unique properties make it a great choice for a multitude of applications.

What are the Benefits of Using PVC?

Polyvinyl Chloride (PVC) is one of the most widely used plastics in the world. It is versatile, durable, and cost-effective. PVC is commonly used in construction, automotive, and medical applications, and has a variety of benefits.

The most obvious benefit of using PVC is its cost-effectiveness. It is less expensive than some other plastics, making it an economical choice for projects. Additionally, PVC is easy to shape and mold, making it a great material for custom projects. It is also lightweight, making it easy to transport and install.

PVC is also durable and long-lasting, making it an ideal choice for projects that need to withstand harsh conditions or heavy use. It is resistant to corrosion, extreme temperatures, and chemicals, and it is fire-resistant as well. PVC is also waterproof, which makes it a great choice for outdoor projects.

PVC is also environmentally friendly. It is non-toxic and can be recycled, making it a great choice for sustainable projects. Moreover, it is easy to clean and maintain, which minimizes waste and increases its longevity.

Overall, PVC is a safe, cost-effective, and environmentally friendly material, making it a great choice for a variety of projects. Its versatility and durability make it an ideal material for custom projects, and its cost-effectiveness makes it an economical choice for a variety of uses.

What are the Drawbacks of Using PVC?

PVC (Polyvinyl Chloride) is an increasingly popular plastic material used in a wide array of products and applications due to its strength, durability, and low-cost production. While PVC is a popular choice in many applications, it is not without its drawbacks. PVC is known to be brittle and can crack or shatter under certain conditions. It is also highly flammable and may release toxic chemicals when burned. Additionally, PVC can be difficult to recycle and often ends up in landfills. PVC is also not biodegradable, so it will remain in the environment for many years. Despite these drawbacks, PVC is an excellent choice for many applications due to its affordability and durability. It is important to weigh the pros and cons of using PVC before making a decision about the material.

FAQs About the What Is The Formula For PVC?

1. What is the difference between PVC and CPVC?

Answer: PVC (Polyvinyl Chloride) is a thermoplastic, which means it can be softened and melted by heat and pressure, while CPVC (Chlorinated Polyvinyl Chloride) is a type of PVC that has been treated with chlorine to make it more resistant to heat and pressure.

2. How do I calculate the amount of PVC needed for a project?

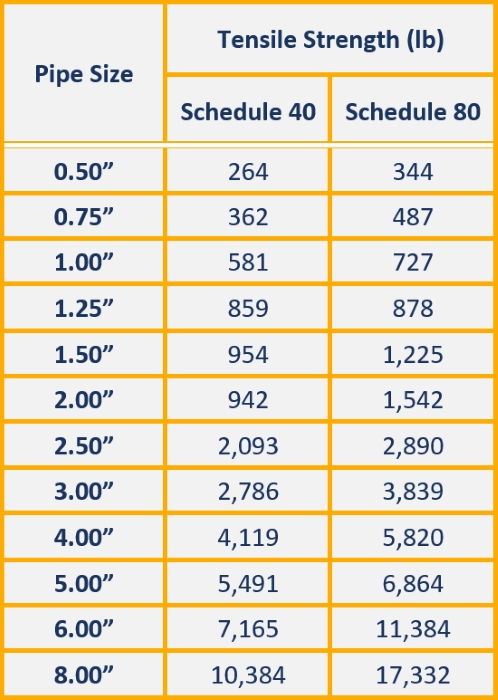

Answer: The amount of PVC needed for a project depends on the size, shape, and complexity of the project. To calculate the amount of PVC needed, measure the length and width of the project, then multiply those measurements together to determine the total square footage. Divide the total square footage by the area covered by one piece of PVC, which is usually 2 square feet, to determine the number of pieces of PVC needed.

3. What type of adhesive should I use for a PVC project?

Answer: PVC projects require a special adhesive designed specifically for PVC. There are a variety of types of PVC adhesives available, depending on the type of PVC you are using and the type of project you are working on. It is important to read the label and instructions carefully before applying the adhesive so you can ensure the best possible results.

Conclusion

The formula for polyvinyl chloride (PVC) is (C2H3Cl)n. PVC is a versatile and economical thermoplastic polymer widely used for a variety of applications, including piping, insulation, and packaging. It is extremely durable and resistant to both chemicals and temperature extremes, making it a popular choice for many industrial and consumer products. It is also easy to manufacture, making it economical and widely available.