What Is The Name Of Pipe Fittings?

Pipe fittings are components used for connecting, controlling, and directing the flow of materials through a piping system. They come in a wide variety of materials, shapes, and sizes, and are used in many plumbing, industrial, and HVAC applications. Different types of pipe fittings include elbows, tees, couplings, unions, flanges, reducers, adapters, caps, plugs, and valves. Each type has its own purpose and is designed to meet certain requirements for pressure, temperature, and other performance specifications.

Types of Pipe Fittings

Pipe fittings are essential components of any plumbing system, and the type of fitting you choose can have a significant impact on the overall performance and longevity of your system. Pipe fittings come in a variety of shapes, sizes, and materials, and are used to connect pipes together, redirect the flow of water, and change the pressure, direction, and flow of the water. From tees and elbows to couplings and unions, there are many different types of pipe fittings available, each with its own purpose and unique features.

Tees, for example, are used to connect three pipes running in different directions. Elbows are used to create a 90-degree angle in a pipe run, while couplings are used to join two pipes of the same diameter. Unions are used to create a connection between two separate pipes, allowing for easy disassembly and maintenance. Flanges are used to join two pieces of pipe together and are usually welded or bolted together.

Other types of pipe fittings include valves, which control the flow of water in the pipes, and caps, which are used to close the end of a pipe. Pipe nipples are short lengths of pipe used to connect two pipes of different sizes, while bushings are used to connect two pipes of different diameters. Finally, adapters are used to connect two pipes of different types, such as plastic to metal.

No matter what type of pipe fittings you need for your plumbing system, it’s important to choose the right type for the job. Not only will this ensure the best performance and longevity of your system, but it will also save you time and money in the long run.

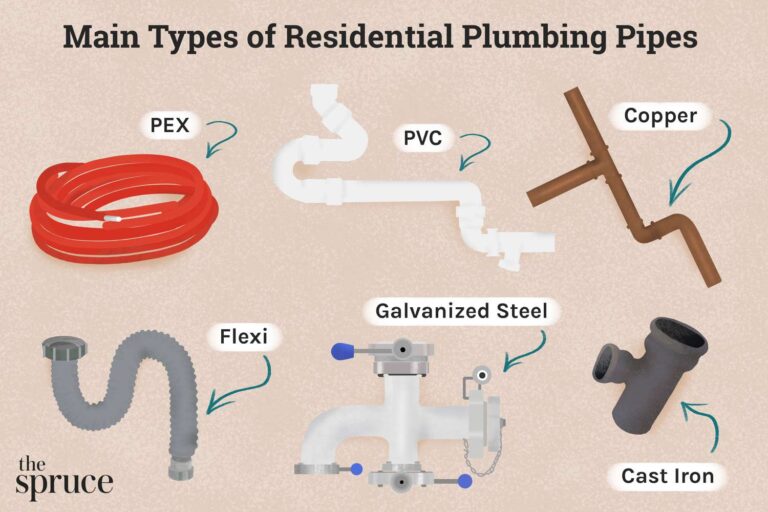

Materials Used in Pipe Fittings

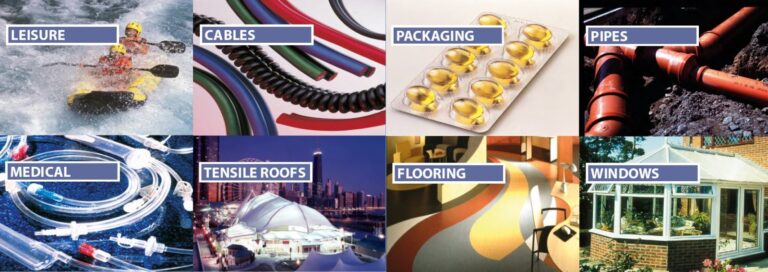

Pipe fittings are essential components used to connect pipes and other plumbing fixtures. They are available in a variety of materials, from metal to plastic, and come in many shapes and sizes to meet a range of needs. Each material has its own unique properties that make it ideal for certain applications, and it is important to select the right materials for the job.

Metals, such as copper, steel, and brass, are the most common materials used in pipe fittings. Copper is known for its high strength and corrosion resistance, making it a popular choice for outdoor applications. Steel is strong and durable, and is often used in industrial applications. Brass is also strong and corrosion-resistant, and is often used for decorative purposes.

Plastics are an increasingly popular choice for pipe fittings due to their low cost, light weight, and resistance to corrosion. PVC, CPVC, and ABS are the most common types of plastic used in pipe fittings. PVC is a common material used for plumbing, and CPVC is often used for hot and cold water lines. ABS is often used for drain lines.

In addition to metal and plastic, there are also other materials used for pipe fittings, such as rubber and ceramic. Rubber is often used for sealing joints, while ceramic is often used for decorative purposes.

No matter the material, it is important to select the right pipe fittings for the job. The material should be able to withstand the temperature and pressure of the application, and should be compatible with the other components of the plumbing system.

Advantages and Disadvantages of Different Types of Pipe Fittings

Pipe fittings are essential components of any plumbing system, allowing for changes in direction, flow, and connection to other piping systems. They come in a range of materials, sizes, and shapes, and each offers unique advantages and disadvantages. For instance, metal fittings are strong and corrosion-resistant, but they may be more expensive than plastic or rubber ones. On the other hand, plastic and rubber fittings offer flexibility and are easy to install, but they may not be as durable or as resistant to temperature changes as metal ones.

No matter what type of pipe fitting you choose, it’s important to understand the advantages and disadvantages of each to make the best decision for your project. For instance, steel pipe fittings can be incredibly strong and durable, but they require extra insulation to protect against temperature fluctuations and corrosion. Copper fittings are resistant to corrosion, but they may not be as strong as stainless steel ones. Plastic and rubber fittings are lightweight and easy to install, but they may not be suited for high-pressure applications.

The right pipe fitting for your project will depend on a variety of factors, including your budget, the type of plumbing system you plan to use, and the type of application you plan to use it for. Knowing the advantages and disadvantages of each type of fitting will help you make the best decision for your project.

How to Select the Correct Pipe Fitting for Your Application

Pipe fittings are essential components of plumbing and piping systems, and they come in a variety of shapes, sizes, and materials. Selecting the right one for your application can be a daunting task. To help make the process easier, it is important to understand the basics of pipe fittings, the different types available, and the factors to consider when choosing the right one.

There are two main categories of pipe fittings: compression and threaded. Compression fittings are used to create a watertight or airtight seal by compressing the pipe against the fitting. Threaded fittings are used to connect two pieces of pipe together by using a thread on the outside of the fitting. For both types of fittings, it is important to ensure that the diameter, material, and threading of the fitting match the pipe.

The type of pipe fitting you choose will depend on the application. For example, if you are installing a water line, you will want to use a fitting that is water-resistant, such as brass or copper. For an air line, you would want to use a plastic pipe fitting. It is also important to consider the pressure rating of the fitting and the local codes and regulations.

When selecting the right pipe fitting for your application, it is important to consider the material, size, and type of fitting. Additionally, make sure to check the local codes and regulations to ensure that your installation is up to code. With the right pipe fitting, you can be sure that your plumbing or piping system will be safe and secure.

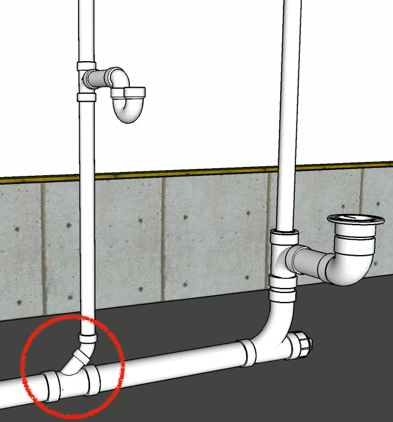

Installation of Pipe Fittings

Pipe fittings are components used to join two or more pipes together. They come in a variety of shapes and sizes, and are used to connect pipes of different sizes and materials. Pipe fittings come in a variety of materials, including brass, copper, PVC, and stainless steel. Installing pipe fittings correctly is a critical part of any plumbing job. It is important to ensure that the fittings are properly installed and that they are of the correct size and material for the pipes they are connecting. If the fittings are incorrectly installed, leaks can occur, leading to costly repairs.

When installing pipe fittings, it is important to consider the type of pipe they are connecting, the amount of pressure they are subjected to, and the temperature the pipes are exposed to. Different fittings will be required for different types of pipes and for different applications. For example, if the pipes are exposed to high temperatures, then fittings made from brass, copper, or stainless steel will be required. It is also important to ensure that the fittings are properly sealed to prevent leaks.

When installing pipe fittings, it is important to follow the manufacturer’s instructions. It is also important to make sure that the fittings are securely attached and that they are compatible with the pipe size and material. If the fittings are not securely attached, then leaks can occur, leading to costly repairs.

Installing pipe fittings correctly is essential to the success of any plumbing job. It is important to ensure that the fittings are of the correct size and material for the pipes they are connecting and that they are properly sealed to prevent leaks. Following the manufacturer’s instructions and ensuring that the fittings are securely attached are critical elements of a successful pipe fitting installation.

Maintenance of Pipe Fittings

Pipe fittings are an integral part of any plumbing system and require regular maintenance to ensure their longevity and proper operation. Poorly maintained fittings can lead to leaks, clogs, and other issues that can cause costly damage and disruption. Fortunately, maintaining pipe fittings is relatively straightforward, and doesn’t require any specialized tools or expertise.

The first step in maintaining pipe fittings is to inspect them for signs of deterioration or damage, such as corrosion, cracking, discoloration, or excessive wear. If any of these signs are present, it’s important to replace the fitting as soon as possible to prevent further damage.

In addition to inspecting for damage, it’s also important to regularly check for leaks. Leaks can occur due to faulty pipe fittings, and can cause significant water damage if left unaddressed. To check for leaks, turn off the water to the fitting and look for water leaking out of the connection points. If a leak is present, either repair or replace the fitting as soon as possible.

Finally, it’s important to clean pipe fittings regularly to prevent clogs and other issues. A simple solution of water and baking soda can be used to clean the fittings, and a soft brush can be used to scrub away any dirt or debris. After cleaning, be sure to rinse the fittings with water to ensure they are completely clean.

By regularly inspecting, checking for leaks, and cleaning pipe fittings, you can ensure that they are in good working condition. This will help you avoid costly repairs and water damage, and ensure that your plumbing system is running as efficiently as possible.

FAQs About the What Is The Name Of Pipe Fittings?

Q1: What types of pipe fittings are available?

A1: There are many different types of pipe fittings available, including elbow fittings, couplings, flanges, reducers, unions, tees, and more.

Q2: How do I choose the right pipe fitting for my project?

A2: When choosing pipe fittings, it is important to consider the material, size, and shape of the fitting. Make sure the fitting is compatible with the material and size of the pipe you are using, and that it is the right shape for your project.

Q3: What is the difference between a pipe fitting and a pipe joint?

A3: A pipe fitting is a component used to connect two pipes, while a pipe joint is a connection between two pieces of pipe. Pipe fittings are available in many different shapes and materials and are used to join pipes together.

Conclusion

Pipe fittings are an essential part of any plumbing system. They provide a secure connection between pipes and other components, allowing water and other liquids to flow freely throughout a plumbing system. The name of pipe fittings can vary depending on the type of fitting being used, such as elbows, tees, couplings, and reducers. Choosing the correct pipe fitting for a particular application is essential for a successful plumbing system.