Why CPVC Pipes Are Used?

CPVC (Chlorinated Polyvinyl Chloride) pipes are widely used in the construction and plumbing industries due to their durability, affordability, and flexibility. CPVC pipes have a wide range of applications, from residential plumbing projects to industrial applications. They are also often used in chemical processing systems, thanks to their resistance to corrosion. CPVC pipes are easy to install, which makes them an ideal choice for both homeowners and professional plumbers. Additionally, CPVC pipes are resistant to temperature variations, making them a good choice for hot and cold water systems. They stand up well to wear and tear, and their flexibility makes them easy to work with. All these advantages make CPVC pipes a great choice for a variety of applications.

Overview of CPVC Pipes

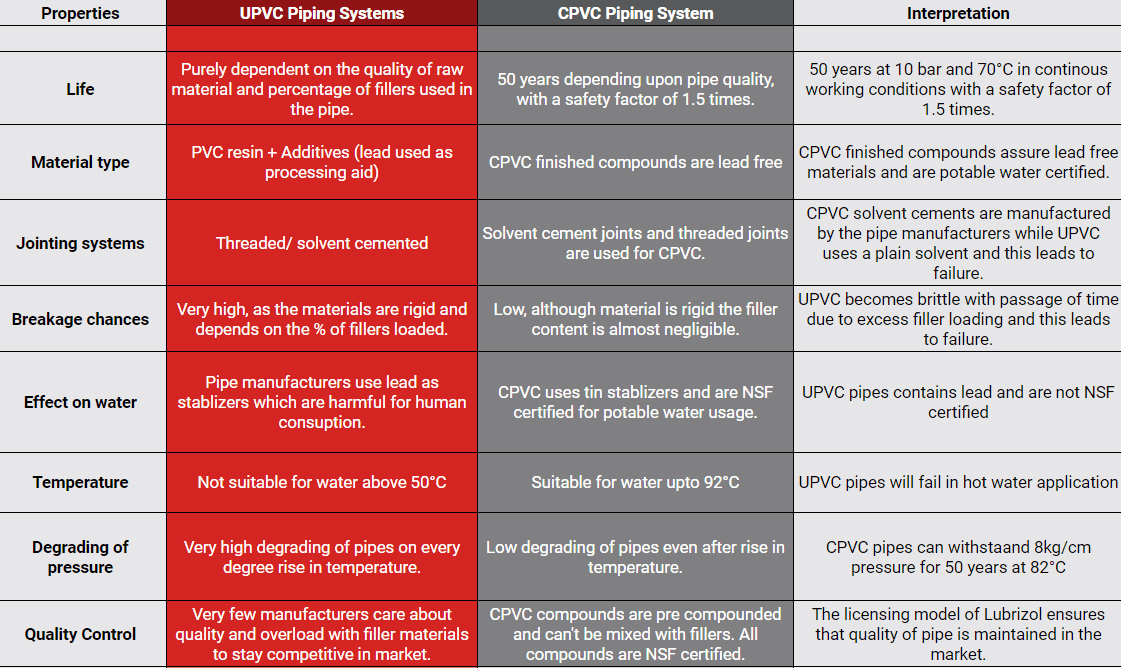

CPVC (chlorinated polyvinyl chloride) pipes are a specialized type of plastic piping used for hot and cold water plumbing systems. CPVC pipes are durable, cost-effective, and easy to install, making them a popular choice in residential and commercial plumbing systems. While CPVC pipes are strong and resistant to corrosion and chemicals, they are also more flexible than metal or PVC piping, allowing for easier installation in tight spaces.

CPVC pipes are composed of a thermoplastic material that is highly resistant to high temperatures, making them a great choice for hot water applications. The internal diameter of CPVC pipes is larger than that of PVC pipes, allowing for greater water flow. Additionally, CPVC pipes are resistant to scaling, a common problem with metal pipes.

A major benefit of CPVC pipes is that they are less expensive than traditional metal piping, making them a great choice for budget-conscious homeowners and businesses. CPVC pipes are also easy to install, which is one of the main reasons why they are so popular among DIYers. In addition, CPVC pipes require minimal maintenance and are resistant to corrosion, making them a great long-term investment.

Overall, CPVC pipes are an excellent choice for hot or cold plumbing systems. They are strong, durable, and cost-effective, and they are easy to install in tight spaces. CPVC pipes are corrosion-resistant and require minimal maintenance, making them a great long-term investment.

Advantages of Using CPVC Pipes

CPVC (Chlorinated Polyvinyl Chloride) pipes are becoming increasingly popular for a variety of applications due to their unique properties. CPVC pipes have a high resistance to corrosion and are more durable than traditional metal pipes. They are also lightweight, flexible, and can be easily cut to size. These pipes are also very cost-effective, making them ideal for a variety of applications.

CPVC pipes are known for their superior chemical resistance and are often used in applications where corrosive materials are present. They also have excellent fire resistance and can withstand temperatures up to 140°C without suffering any damage. CPVC pipes are also non-toxic, making them safe for use in applications where human contact is possible.

CPVC pipes are easy to install and require minimal maintenance. They are also resistant to cracking and splitting, making them more reliable than traditional metal pipes. CPVC pipes are also resistant to UV radiation, making them ideal for outdoor applications.

CPVC pipes offer a wide range of advantages, making them an ideal choice for a variety of applications. They are cost-effective, durable, lightweight, and resistant to corrosion, fire, and UV radiation. They are also easy to install and require minimal maintenance. With these advantages, it is easy to see why CPVC pipes are becoming increasingly popular.

Disadvantages of Using CPVC Pipes

CPVC (Chlorinated Polyvinyl Chloride) is a type of plastic piping used for a variety of purposes, from plumbing to drainage. It is a popular choice for many applications due to its low cost and its durability. However, like any material, CPVC has both advantages and disadvantages. This article will discuss the potential drawbacks of using CPVC pipes.

One disadvantage of CPVC pipes is that they are more prone to cracking and splitting than other types of plastic piping, especially in colder climates. Additionally, CPVC pipes are not as strong as some other types of piping, such as ABS (Acrylonitrile Butadiene Styrene) plastic pipes. This means that CPVC pipes may not be the best choice for applications that require a great deal of strength or durability.

Another potential downside of CPVC is that it is not as resistant to heat as some other types of plastic. In fact, CPVC pipes can begin to soften and deform when exposed to temperatures over 180°F (82°C). This means that CPVC pipes may not be suitable for applications that require a great deal of heat resistance.

Finally, CPVC pipes may be more prone to leaks than other types of plastic piping. This is due to the fact that CPVC is softer and more flexible than other types of piping, which can make it easier for water to seep through.

Overall, CPVC is a popular choice for many applications due to its low cost and durability. However, it is important to be aware of the potential drawbacks of using CPVC pipes, such as their tendency to crack and split, their lower strength, their lack of heat resistance, and their potential for leaking.

Applications of CPVC Pipes

CPVC (Chlorinated Polyvinyl Chloride) pipes are a type of plastic piping used for both residential and commercial applications. CPVC pipes are most commonly used in plumbing and water supply systems, but they can also be used in other applications, such as industrial and medical. CPVC pipes are highly resistant to corrosion and can be used in a variety of conditions, including hot and cold temperatures. Additionally, CPVC pipes are lightweight and easy to install.

CPVC pipes are ideal for residential and commercial applications due to their low cost, durability, and ease of installation. They can be used for a wide variety of applications, including: water supply systems, irrigation systems, wastewater systems, gas lines, and HVAC systems. Additionally, CPVC pipes can be used for industrial applications, such as chemical processing and food processing. They are also used in medical applications, such as for oxygen delivery.

CPVC pipes are a cost-effective and durable solution for many applications. They are resistant to corrosion and can withstand extreme temperatures. Additionally, they are lightweight and easy to install, making them an ideal choice for both residential and commercial applications.

Cost Considerations of CPVC Pipes

CPVC pipes, or chlorinated polyvinyl chloride pipes, are a type of piping commonly used in plumbing. CPVC pipes are known for their strength, durability, and affordability. But, when considering CPVC pipes for a project, it’s important to take cost into account. CPVC can be more expensive than other piping options, and some projects may require more complex installation, which can further increase costs. In addition, CPVC pipes require more maintenance than other types of piping, which can add to the overall cost of the project.

When looking at cost considerations for CPVC pipes, it’s important to consider the long-term benefits of the material. CPVC can last up to 50 years with proper maintenance, making it an excellent investment for many home and commercial projects. CPVC is also resistant to corrosion, making it a great choice for applications where corrosive chemicals or liquids are present. Furthermore, CPVC pipes are fire-resistant, making them a safe option for many types of construction.

Overall, CPVC pipes can be a great choice for many projects. However, it’s important to weigh the cost considerations before deciding if CPVC is the right choice. When the long-term benefits are taken into account, CPVC can often be the best option for many home and commercial projects.

Installation Requirements for CPVC Pipes

CPVC, or chlorinated polyvinyl chloride, is a type of piping used in a variety of plumbing and industrial applications. It is an inexpensive and durable material that is capable of withstanding harsh chemicals and temperatures. But in order for CPVC pipes to perform as intended, they must be installed correctly.

In order to ensure proper installation of CPVC pipes, a few steps must be followed. First, CPVC must be cut to size using a saw with a fine-tooth blade, as this ensures a smooth and even cut. It is also important to make sure the ends of the pipes are clean and free of debris. Next, CPVC cement must be applied to the ends of the pipes before they are joined together. The pipes should then be joined together, making sure to hold them in place for a few minutes until the cement has dried.

Finally, CPVC pipes should be tested for leaks before use. This can be done by filling the pipes with a solution of soapy water and then checking for bubbles. If the connections are secure, no bubbles will form.

These steps are important to ensure that CPVC pipes are properly installed and will perform optimally. When installing CPVC pipes, it is important to follow the manufacturer’s instructions carefully and to use the correct tools and materials. Doing so will help ensure that the pipes last for many years.

FAQs About the Why CPVC Pipes Are Used?

Q1. What are CPVC pipes made of?

A1. CPVC pipes are made of a type of plastic called chlorinated polyvinyl chloride (CPVC). This type of plastic is highly resistant to corrosion and has excellent fire-retardant properties.

Q2. What are the advantages of using CPVC pipes?

A2. CPVC pipes offer several advantages over traditional metal pipes, such as lower installation costs, fewer joints, faster installation, and better resistance to corrosion and temperature changes. Additionally, CPVC pipes are less likely to develop leaks over time.

Q3. What types of applications are CPVC pipes used for?

A3. CPVC pipes are commonly used for residential hot and cold water applications, as well as irrigation systems and industrial process lines. Additionally, CPVC pipes are often used in chemical and industrial applications where high temperatures or corrosive chemicals are present.

Conclusion

CPVC pipes are used in many applications due to their durability, high temperature resistance, and cost-effectiveness. CPVC pipes have excellent chemical resistance, making them suitable for a wide range of applications, including hot and cold water pipes, industrial chemical plants, and general plumbing systems. CPVC pipes are also resistant to fire and corrosion, making them an ideal choice for many applications. In addition, CPVC pipes are easy to install, require little maintenance, and are relatively inexpensive. Overall, CPVC pipes are a great choice for many applications and can provide a cost-effective solution for many plumbing projects.