Why Is PVC Used?

PVC (Polyvinyl Chloride) is a widely used plastic material that has a variety of uses. It is a strong, durable, and lightweight material that can be easily molded or shaped into a variety of products. PVC is used in a wide range of applications due to its low cost, chemical resistance, and low maintenance requirements. It can be used for piping, window frames, flooring, wall coverings, insulation, and many other construction applications. PVC is also used in medical, automotive, and other industries due to its versatility.

What Is PVC?

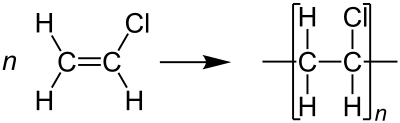

PVC, or polyvinyl chloride, is a widely used plastic material known for its durability and versatile applications in various industries. PVC is a thermoplastic polymer composed of chlorine and carbon, and is produced in both rigid and flexible forms. It is an inexpensive yet strong material, making it suitable for a variety of applications. Its versatility, affordability, and strength make it a common choice for a variety of products such as piping, window frames, flooring, and more. Its ability to resist corrosion, chemical damage, and moisture makes it a popular choice for both commercial and residential applications. Additionally, its non-toxic and recyclable properties make it an environmentally-friendly option. PVC is used across a variety of industries, including construction, automotive, and medical. Its cost-effectiveness and durability make it a favorite among manufacturers and consumers alike.

Properties of PVC

make it an ideal material for a wide range of applications. PVC stands for polyvinyl chloride, a synthetic plastic polymer that is one of the world’s most widely used plastics. PVC has been used in a variety of industries for decades due to its strength, durability, low cost, and versatility.

PVC is renowned for its strength and durability, making it an ideal choice for a variety of applications. It is moisture-resistant, corrosion-resistant, and can withstand extreme temperatures. PVC is also highly flexible, allowing it to be molded into a variety of shapes and sizes. PVC is also known for its low cost and has been used in a variety of low-cost construction projects.

Additionally, PVC is resistant to many chemicals, making it a great choice for chemical processing plants and other industrial applications. PVC can also be easily recycled, making it an environmentally friendly material. It can also be treated with flame retardants to make it more fire-resistant, making it a great option for building materials.

Overall, PVC is an incredibly versatile material that is ideal for a variety of applications. It is strong, durable, flexible, economical, and resistant to many chemicals. PVC is also easy to recycle and can be treated with flame retardants to make it more fire-resistant. With so many benefits, it’s no wonder why PVC has become such a popular material.

Advantages of PVC

PVC, or polyvinyl chloride, is a versatile material used in a wide variety of applications. It is known for its strength and durability, as well as its low cost and easy availability. In addition, PVC has a wide range of advantages that make it an attractive choice for many applications.

PVC is a lightweight material that is also highly resistant to corrosion and chemicals. This makes it ideal for both indoor and outdoor use, as it can withstand a variety of weather conditions. PVC is also impact resistant, which makes it suitable for many products and applications that may be exposed to wear and tear.

In addition to its strength and durability, PVC is also a very cost-effective material. It is relatively inexpensive compared to other materials, making it ideal for projects with limited budgets. PVC is also easy to work with, as it can be cut, shaped, and molded into a variety of shapes and sizes. This can be beneficial for projects that require custom-made components.

Finally, PVC is a non-toxic material that is also recyclable. This makes it a great choice for environmentally conscious projects. It is also flame-resistant, making it ideal for applications in which fire safety is a concern.

Overall, PVC is a cost-effective, durable, and versatile material that is widely used in many applications. Its low cost, easy availability, and wide range of advantages make it an attractive choice for many projects.

Applications of PVC

are widespread due to its versatility and durability. PVC, or polyvinyl chloride, is a type of plastic that is commonly used for a variety of purposes. From construction to medical equipment, PVC is used in many industries due to its durability and affordability. PVC has a wide range of properties that make it an ideal material for many applications. It is flame-retardant, non-corrosive, and resistant to chemicals. It also has excellent electrical insulation properties and is lightweight.

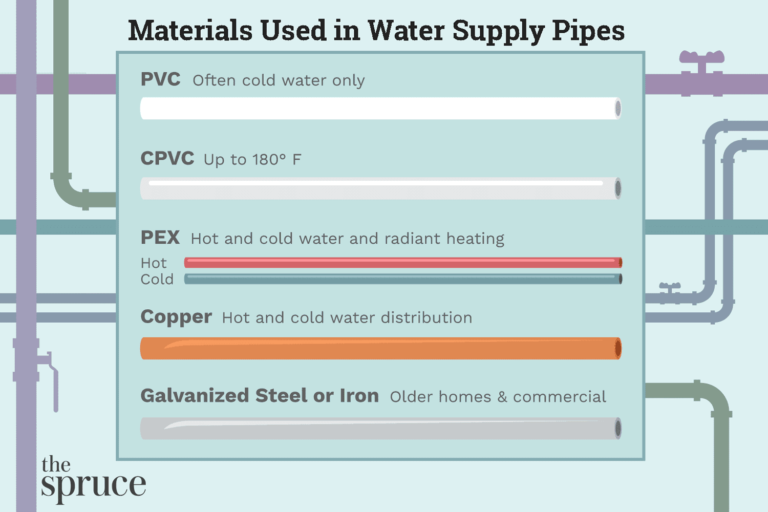

In the construction industry, PVC is often used to make electrical wiring, plumbing pipes, and siding. PVC pipes are used extensively in plumbing and drainage systems due to their low cost, resistance to corrosion, and ability to withstand high temperatures. PVC siding is used to provide insulation and protection from the elements and is often used on commercial and residential buildings.

In the medical field, PVC is used to make a variety of medical equipment such as IV bags, tubing, and catheters. PVC can also be used to make protective suits, gloves, and goggles for medical professionals. PVC is also used to make medical implants and prosthetics due to its biocompatibility and strength.

Lastly, PVC can be used in the automotive industry for a variety of purposes. PVC is often used to make car parts, such as engine parts, gaskets, and fuel lines. It is also used to make car seats and seat covers due to its durability and ability to resist tears and fading.

Overall, PVC is an essential material that is used in many industries due to its versatility and affordability. Its durability, strength, and resistance to corrosion make it an ideal material for a variety of applications.

Production of PVC

(polyvinyl chloride) has seen a massive growth in recent years due to its versatility and abundance of applications. PVC is a thermoplastic polymer that is light, durable, and economical, making it an ideal choice for a variety of uses in industries ranging from construction to healthcare. Its properties make it a great choice for a variety of projects, from window frames to piping.

PVC is made up of chlorine and carbon, which make it resistant to water, acids, heat, and electricity. This makes it ideal for use in outdoor applications, as it can withstand extreme weather conditions and still maintain its strength and integrity. Moreover, PVC has a low flammability rating, making it a suitable choice for areas that require fire-safe materials.

PVC is also recyclable, making it a more sustainable choice than other materials such as wood or aluminum. This helps reduce the environmental impact of large-scale projects, as the material can be reused or even re-purposed. Additionally, PVC is easy to install and requires little maintenance, making it a cost-effective choice for many applications.

The many benefits of using PVC make it the perfect choice for a variety of projects. From its low cost to its durability and recyclability, PVC is a great choice for a variety of projects. With its diverse uses and long-term performance, it is no wonder why PVC is becoming increasingly popular.

Environmental Impact of PVC

PVC (polyvinyl chloride) is a versatile, cost-effective, and popular material choice for a variety of applications. But the environmental impact of PVC is often overlooked. PVC production is a chemical process that uses toxic chemicals, such as ethylene dichloride (EDC) and chlorine gas, to create the material. These chemicals can be released into the environment, contaminating soil and water supplies and posing a risk to human health. Manufacturing PVC also requires large amounts of energy, which can lead to significant greenhouse gas emissions.

Once in use, PVC products can also have a negative impact on the environment. The material is not biodegradable and can take hundreds of years to break down. As a result, it can accumulate in landfills, and the chemicals used to make it can leach out into the environment. PVC also carries an added risk of fire hazards due to its combustible nature. It can produce toxic fumes if burned, which can cause further environmental damage.

Despite the environmental drawbacks of PVC, there are ways to reduce its impact on the environment. Recycling is one option, as PVC can be melted down and reconstituted for reuse in new products. Increasingly, manufacturers are also switching to more sustainable alternatives, such as bioplastics and polyethylene, which are much less harmful to the environment. Ultimately, understanding the environmental impact of PVC is essential in making informed decisions about its use.

FAQs About the Why Is PVC Used?

Q1: What advantages does PVC offer?

A1: PVC offers several advantages, including durability, resistance to corrosion, ease of installation, low cost, and a wide range of colors and textures.

Q2: Is PVC environmentally friendly?

A2: Yes, PVC is an environmentally friendly material that is recyclable and made with limited resources.

Q3: Where is PVC most commonly used?

A3: PVC is most commonly used in construction for pipes, window frames, and flooring, but it is also used in furniture, clothing, electrical insulation, and medical supplies.

Conclusion

PVC is an incredibly versatile and cost-effective material that is used in a wide variety of applications. PVC is used for its durability, strength, and resistance to corrosion, as well as for its cost-effectiveness and versatility. PVC is also environmentally friendly, as it does not contain chlorine or other toxins associated with other plastic materials. As such, PVC is an ideal choice for many different types of projects, from plumbing to construction and more.