What Materials Are Used To Stop Leaks?

Leaks can be dangerous and can cause property damage, health issues, and environmental damage. To prevent and stop leaks, a variety of materials can be used. These materials can range from waterproof sealants to fabrics, tapes, and coatings. Sealants are often used to create a waterproof barrier between two substrates, while fabrics, tapes, and coatings can be used to provide a temporary or permanent solution to a leaky pipe. Additionally, a variety of adhesives and epoxies can be used to seal leaks, while clamps, plugs, and gaskets can also be employed to create a tight seal. Materials such as rubber, plastic, metal, and concrete can also be used to stop leaks, and are often used in combination with other materials for maximum effectiveness.

Types of Leaks and Their Causes

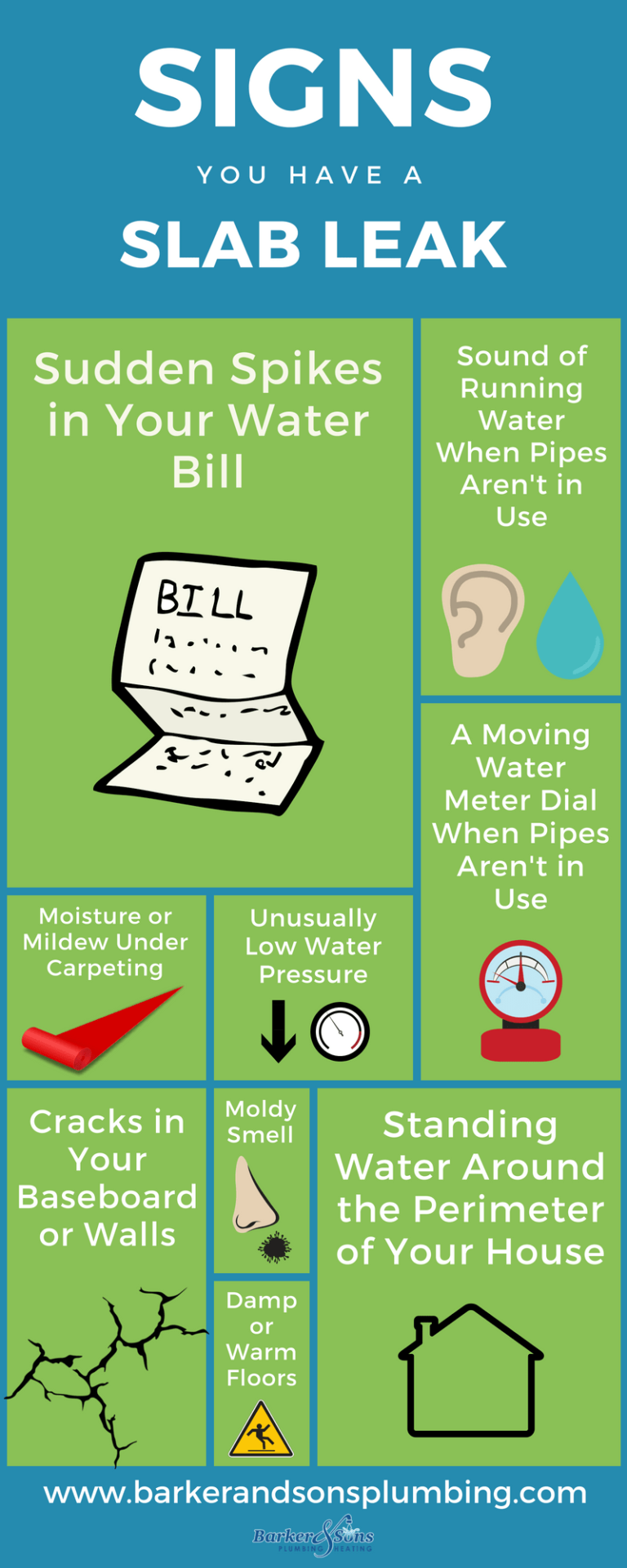

Leaks can occur in many places throughout a home or commercial structure. The most common types of leaks include exterior wall leaks, pipe leaks, window leaks, and roof leaks. Each type of leak has its own unique set of causes and solutions. To understand how to stop leaks, it is important to understand the material used in each type of leak.

Exterior wall leaks are often caused by moisture seeping through small cracks in the wall. To stop water from entering through these cracks, a waterproof sealant is often used to fill them in. This sealant is made of a rubberized material that is designed to be flexible and resistant to water.

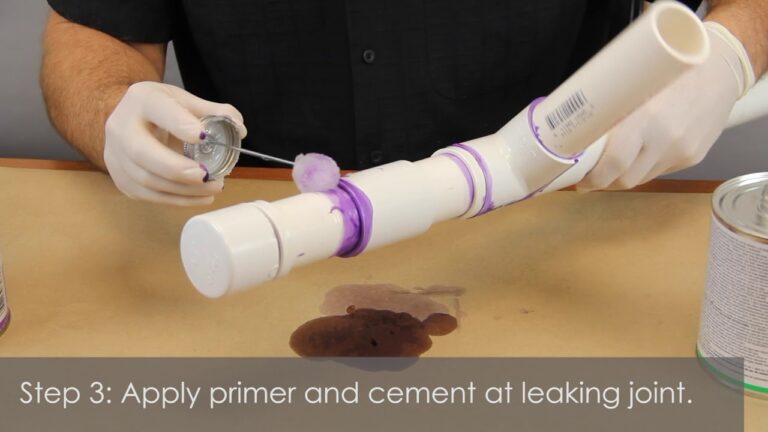

Pipe leaks are usually caused by a broken pipe or a loose connection between two pipes. To prevent water from leaking through these areas, a pipe sealant is often used. This sealant is made of silicone and is designed to be resistant to water and high temperatures.

Window leaks are caused by water seeping through cracks in window frames. To prevent this from happening, a window sealant is often used. This sealant is made of a rubberized material that is designed to be flexible and resistant to water.

Finally, roof leaks are often caused by water seeping through cracked shingles or tiles. To prevent this from happening, a roof coating is often applied. This coating is made of a waterproof material that is designed to be strong and resistant to water.

By understanding the materials used to stop leaks, one can better understand how to effectively prevent and fix them. Each type of leak requires a different material, so it is important to know which one to use to provide the best results.

Different Materials Used to Stop Leaks

Leaks can be a nuisance and can cause a lot of damage to your home or business if not addressed quickly. Fortunately, there are a variety of materials that can be used to stop a leak and prevent further damage. Depending on the type of leak and the location, the material used can vary. Here’s a look at some of the most common materials used to stop leaks:

Caulk: Caulk is a great choice for sealing small cracks and gaps around windows and doors. It’s easy to apply and comes in a variety of colors to match your trim.

Putty: Putty is a great choice for filling small holes in pipes. It’s easy to apply and can be used to seal up small leaks.

Tape: Tape is one of the most common materials used to stop leaks. It’s easy to apply and can be used in a variety of situations.

Epoxy: Epoxy is a great choice for sealing larger cracks and gaps around pipes and fittings. It’s strong and can be used on a variety of surfaces.

Foam: Foam is a great choice for filling larger openings around pipes and fittings. It’s easy to apply and will expand to fill any gaps or cracks.

No matter what type of leak you’re dealing with, there’s a material that can be used to stop it. By using the right material, you can save time and money, and prevent further damage to your home or business.

Advantages and Disadvantages of Different Materials

Leaks can be a major problem in homes and businesses, leading to water damage and requiring expensive repairs. To prevent or stop leaks, different types of materials can be used to seal off pipes and help keep water from entering the surrounding area. Some of the most commonly used materials for stopping leaks include PVC, copper, steel, and galvanized iron. Each type of material has its advantages and disadvantages, and it is important to consider all of these factors before selecting a material for your leak-stopping needs.

PVC is the most popular material for sealing off leaks, as it is relatively inexpensive and easy to install. It is also resistant to corrosion and is available in a variety of sizes and colors. However, PVC can become brittle over time and is not suitable for use in areas with extreme temperatures.

Copper is another option for leak-stopping materials, and is a durable, long-lasting material. It is also resistant to corrosion and is available in a wide range of sizes and colors. However, copper can be expensive, and it is difficult to install.

Steel is an effective material for stopping leaks, and is strong and durable. It is resistant to corrosion and can be used in a variety of applications. However, steel can be difficult to bend and may require welding.

Galvanized iron is also a popular choice for leak-stopping materials. It is durable, corrosion-resistant, and relatively inexpensive. However, galvanized iron can be difficult to cut or shape, and may require welding.

When selecting a material for stopping leaks, it is important to consider each material’s advantages and disadvantages. It is also important to select a material that is suitable for the environment and the application. Taking all of these factors into consideration will help ensure that you choose the best material for your needs.

Application of Different Materials to Different Types of Leaks

Leaks, particularly in industrial and commercial buildings, can cause significant damage to the structure of the building and any equipment inside. This makes it essential to find the right materials to stop the leak. The materials used to stop leaks vary depending on the type of leak and the area it is found in, as each type of material has different properties and capabilities. Some materials used to stop leaks are concrete, metals, rubber, plastic, and more.

Concrete is a popular material for stopping leaks in foundations, walls, and floors. It is a material that is strong, durable, and resistant to water. Metals, such as aluminum, copper, and stainless steel, are also used to stop leaks. These materials are resistant to corrosion and can be easily molded into shapes needed to fit the structure of the building. Rubber is also used to stop leaks in pipes and hoses due to its flexibility and water-resistant properties. Plastic is another material that can be used to stop leaks, as it is lightweight and flexible.

No matter the type of leak, it is important to select the right material to stop it. Different materials have different properties that make them suitable for different types of leaks. Knowing the type of leak and the area it is in can help determine the best material for the job. By using the right material, it is possible to stop the leak and prevent further damage to the building.

Considerations for Selecting the Appropriate Material

Leaks are a common problem in many residential and commercial buildings, and it is essential to use the right material to stop them. Selecting the right material for the job requires an understanding of the different types of materials available and how they can be used to stop leaks. This article will cover the different materials used to stop leaks, their advantages and disadvantages, and considerations for selecting the best material for the job.

When selecting a material for a leak repair, it is important to consider the type of leak, the size of the leak, and the environment in which the repair will take place. For instance, materials that are best suited for wet environments may not be suitable for dry ones. Additionally, materials such as rubber, plastic, or metal may be better suited for small leaks, while larger ones may require more durable materials such as concrete or asphalt.

Moreover, it is also important to consider the cost of the material about the size and scope of the repair. While some materials, such as rubber, may be cheaper, they may not be as durable as other materials. Additionally, some materials may require special tools or equipment for the repair, which can also add to the cost.

Finally, it is important to consider the aesthetic and environmental impact of the material. For instance, some materials such as PVC or metal may be more visually appealing than concrete, but they may also have a negative environmental impact.

In conclusion, selecting the right material for a leak repair requires an understanding of the different materials available, their advantages and disadvantages, and the scope and size of the repair. Additionally, it is important to consider the cost, environment, and aesthetic impact of the material when making a decision. With this information, it is possible to select the best material for the job and ensure a successful repair.

Maintenance and Quality Control of Leak Stoppers

From time to time, it is important to check the quality and maintenance of materials used to stop leaks. Ensuring that the seals are in good condition can prevent further damage to a building or structure. It is necessary to check the condition of the sealants, gaskets, and other materials used to stop leaks regularly to ensure they are performing their job correctly. Sealing materials come in a variety of materials, including rubber, plastic, metal, and composite materials. Each material has its characteristics and should be checked for quality and durability.

Inspecting the material used to stop leaks is important for many reasons. It can help determine if the material is suitable for the job and if it is deteriorating or losing its effectiveness. Additionally, it can help determine if the material is prone to environmental damage, such as corrosion, UV damage, or extreme temperature variations. It is also important to assess the material for physical damage, such as cracks or tears.

The most important part of the leak-stopping process is finding and fixing the source of the leak. However, it is also important to use quality materials and maintain them regularly. Doing so can help ensure that the leak is stopped quickly and efficiently and that the structure is protected from further damage.

FAQs About the What Materials Are Used To Stop Leaks?

1. What types of products are best for sealing a leak?

A variety of products can be used to seal a leak, including caulk, sealants, epoxy, and tape. Depending on the type of material and size of the leak, some products may be more suitable than others.

2. How do I know if the material I am using will stop the leak?

It is important to ensure that the material you are using is appropriate for the job. If you are using a sealant, it should be designed for the type of material you are working with. Additionally, you should ensure that the product has been approved by the manufacturer for use in the application.

3. What should I do if the leak persists after I have used a material to seal it?

If the leak persists after attempting to seal it, you may need to investigate further. You should check to see if the material was properly applied and if there is another underlying cause for the leak. In some cases, it may be necessary to replace the material or take other action to fix the problem.

Conclusion

The materials used to stop leaks depend on the type of leak, the location, and the severity. Common materials used to stop leaks include caulking, sealants, epoxy, and tape. In some cases, more extreme measures such as welding or soldering may be necessary. Ultimately, the right material to stop a leak will depend on the specific situation.