How Dangerous Is Lead Solder In Plumbing?

Lead solder is a component used in plumbing systems to help join pipes and fittings together. While lead solder is a reliable and cost-effective choice for plumbing jobs, it can be dangerous if it is not handled correctly. Lead solder can emit lead-containing dust, which can be hazardous if inhaled or ingested. This dust can also settle on food and other surfaces, leading to potential lead exposure. Therefore, it is important to take the proper precautions when using lead solder in plumbing. These precautions include wearing protective gear, using adequate ventilation, and disposing of scrap lead solder in a responsible manner.

What is Lead Solder?

Lead solder is a type of alloy material made up of a combination of tin and lead. It is commonly used in the electronics and plumbing industries because it has superior properties that make it suitable for soldering and welding. Lead solder is malleable and has a low melting point, which makes it excellent for forming tight seals and connections. It is also non-corrosive and able to withstand high temperatures. The lead in lead solder adds strength and durability to the bond, making it a great choice for plumbing, electronic and electrical applications. Lead solder is widely used in industry and is an essential tool for any professional or hobbyist working with plumbing or electronics.

Potential Health Risks of Lead Solder

The use of lead solder has long been a go-to for joining metals and other materials, but the potential health risks associated with prolonged exposure to lead solder should not be overlooked. Lead solder is made of a mixture of tin and lead, and when heated, the lead fumes can be inhaled or absorbed into the skin. Prolonged exposure to lead solder can lead to a variety of ailments, including damage to the nervous system, reproductive organs, kidneys, and GI tract. It can also cause long-term cognitive and behavioral problems, including coma, seizures, and even death. To minimize the risks of exposure, it is important to use lead-free solder when possible, and to take all necessary safety precautions when working with lead solder.

Regulations and Standards of Lead Solder

Lead solder is an essential material in many industries, as it is used to create strong and lasting bonds between metals. However, in order to ensure that these bonds are of the highest quality and that they are safe for people and the environment, there are specific regulations and standards that must be followed when using lead solder. These regulations and standards ensure that lead solder is being used in a safe and effective manner, and that the bonds created are as strong as possible. Furthermore, these regulations and standards ensure that the lead solder used is of high quality and that it meets the specific requirements of the industry in which it is being used. By following regulations and standards for lead solder, businesses can rest assured that their products are safe and reliable.

Alternatives to Lead Solder

When it comes to electrical connection, lead solder is not the only option. There are a variety of alternatives to lead solder that can be used for various tasks. From flux-free solder that eliminates the need for additional cleaning to low temperature solders that reduce the risk of damaging components, there are a wide range of options that can be used in place of lead-based solder. Other alternatives include conductive silver epoxy, non-solder electrical connectors, and heat shrink tubing. Each of these options provides a safe and reliable solution for many electrical connection needs, and can be a great alternative to lead solder.

Tips for Identifying Lead Solder

Lead solder has been used in the electronics industry for decades, but it is now being phased out due to health and environmental concerns. Identifying lead solder can be a challenge and requires a few tips.

First, look for a soft texture on the surface of the solder. Lead solder is much softer than other types of solders and can be easily manipulated by hand. If it is hard and brittle, it is likely not lead solder.

Second, check the color of the solder. Lead solder is usually dull gray to white in color, while other types of solders may be bright silver.

Third, look for any markings on the solder. Lead solder is usually marked with the letters “PB” or “Pb” somewhere on the surface.

Finally, you can use a lead test kit to definitively determine if the solder contains lead. Lead test kits can be purchased at most hardware stores.

Knowing how to identify lead solder is important for anyone working with electronics. By following these tips, you can quickly and easily determine whether lead solder is present.

FAQs About the How Dangerous Is Lead Solder In Plumbing?

1. Is lead solder safe to use in plumbing?

Answer: Lead solder is not safe for use in plumbing, and it is illegal to use lead solder in many countries. In the United States, the Safe Drinking Water Act of 1974 prohibits the use of lead solder in plumbing that comes in contact with drinking water.

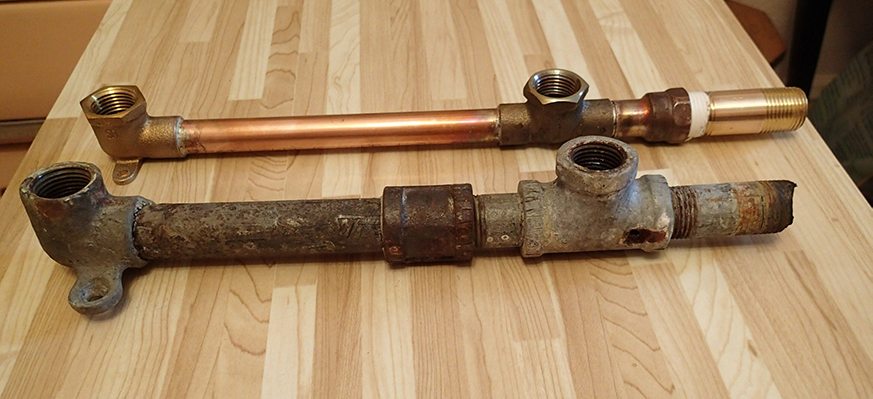

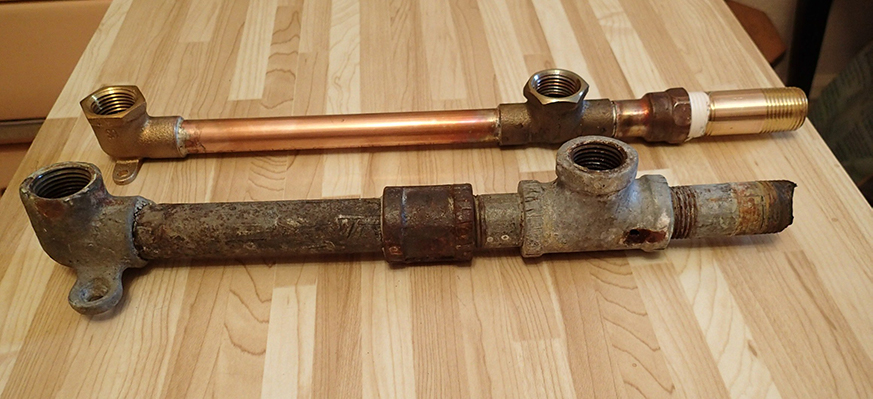

2. How can I tell if my plumbing contains lead solder?

Answer: Lead solder is usually silver in color and can be identified by its distinct, dull look. You can also test the solder by using a lead test kit.

3. What are the health risks of lead solder in plumbing?

Answer: The health risks of lead solder in plumbing include lead poisoning, which can cause a range of health problems, including brain damage, kidney damage, and behavioral problems. Long-term exposure to lead can also lead to an increased risk of cancer.

Conclusion

Lead solder is a hazardous material that can cause serious health problems if not handled properly. It is important to be aware of the potential dangers of lead solder when performing plumbing work and to take the necessary precautions to protect oneself and others from the toxic effects of lead. Some of the most common ways to protect against lead exposure include using lead-free solder, wearing protective equipment, and properly disposing of scraps. Although lead solder can be dangerous, it can be safely used by taking the necessary precautions to ensure the safety of everyone involved.