How Do You Use A Repair Coupling?

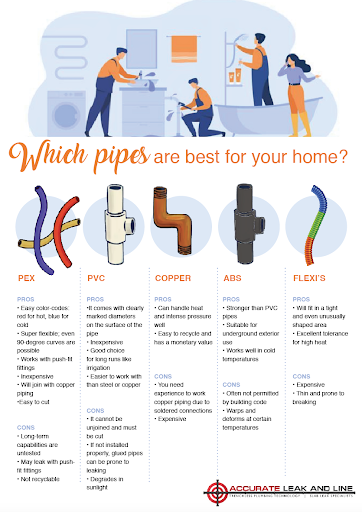

A repair coupling is a plumbing device that is used to connect two pipes together. It is typically used when one pipe needs to be repaired or replaced. It is quick and easy to install, allowing water to be back on and the repair to be completed in a timely manner. Repair couplings come in a variety of materials and sizes to fit any application. They are available in PVC, copper, brass, and stainless steel. Installation requires cutting the pipe, installing the repair coupling, and securing it with the appropriate sealant or adhesive.

What is a Repair Coupling?

A repair coupling is an essential plumbing tool used to join two pipes or tubing sections together, usually made of PVC, metal, or copper. It is a convenient and easy to use alternative to soldering, which can be time-consuming and difficult. Repair couplings are available in a variety of sizes, materials, and configurations, making them suitable for a wide range of plumbing applications.

Using a repair coupling is relatively straightforward. First, you will need to measure the length of the pipe or tubing you are connecting and then select a repair coupling that is the right size. Next, you will need to cut the pipe or tubing to the correct length and then use a saw or file to remove any burrs or sharp edges. Finally, you will need to align the two pieces of pipe or tubing and then slide the repair coupling over them. You may need to use a wrench or pliers to tighten the coupling once it is in place.

In conclusion, repair couplings are an invaluable tool for any plumbing project, allowing for quick and easy connections between pipes and tubing sections. With the right preparation and supplies, you can use a repair coupling to make quick and secure connections in no time.

What Types of Repair Couplings Are Available?

When it comes to repairing damaged or worn-out pipes or plumbing fixtures, repair couplings are often the most efficient and cost-effective solution. Repair couplings come in a variety of sizes, materials, and designs to meet the needs of any repair job, from small scale home plumbing projects to large-scale industrial operations. Depending on the situation, several types of repair couplings are available to choose from.

Compression fittings are the most common type of repair coupling, consisting of a nut and sleeve-type mechanism that is tightened around the pipe to create a secure, watertight seal. Compression couplings are often used to connect copper, brass, or plastic pipes, and can be easily installed without needing additional tools or fittings.

Flexible repair couplings are designed to easily join mismatched pipes without the need for soldering or welding. These couplings are made from a flexible rubber material that stretches out to fit over the ends of two different sized pipes, and then compresses to form a leak-proof connection. This type of coupling is ideal for joining pipes in areas that require frequent maintenance, as it can easily be taken apart and reassembled with minimal effort.

Flange couplings are typically used to connect larger diameter pipes, and are composed of two flanges which are connected with bolts and gaskets. Flanges are available in a range of materials to suit different applications, and can be used to connect pipes of different sizes, materials, and lengths.

For more complicated repairs, specialty couplings such as repair saddles and wrap-around sleeves can be used. These couplings are designed to form a strong watertight seal around the pipe, even when the surrounding environment is extremely corrosive or abrasive.

No matter the type of repair job, there is a repair coupling available to get the job done. By understanding the different types of couplings available, and choosing the right one for the job, it is possible to complete any repair job quickly and efficiently.

How to Install a Repair Coupling

Installing a repair coupling is an important part of any plumbing job. When a damaged pipe needs to be repaired, using a repair coupling can be an effective and efficient solution. Repair couplings are especially useful in areas where access to the pipe is limited, as they can be installed from one side of the joint, without having to cut out or remove any of the existing pipe.

When installing a repair coupling, it is important to ensure that the pipe is clean and free from debris. This will help to ensure that the repair coupling will be able to provide an effective seal. Once the pipe is clean, the repair coupling should be aligned with the pipe and tightened using an appropriate wrench. The coupling should also be checked for any leaks once it has been tightened.

In some cases, a repair coupling may need to be secured to the pipe using clamps. If this is necessary, the clamps should be properly secured and tightened. It is also important to check the clamps after they have been tightened to make sure that the repair coupling is secure.

Finally, it is important to check the repair coupling after it has been installed. This will help to ensure that it is providing a tight seal and that it is not leaking. If any leaks are detected, the repair coupling should be tightened again, or replaced if necessary. Following these steps will help to ensure that the repair coupling is properly installed and providing a secure seal.

Advantages of Using a Repair Coupling

Repair couplings provide a simple, effective solution for repairing broken pipes. Repair couplings are used to mechanically join two pieces of pipe together, forming a continuous and secure connection. Not only are repair couplings easy to install, but they also offer a number of advantages over traditional methods of pipe repair. Here are some of the key benefits of using a repair coupling.

Firstly, repair couplings are incredibly cost-effective. With a repair coupling, it is possible to quickly and inexpensively repair damaged pipes with no need for expensive replacements. Repair couplings also provide a secure connection that is watertight and leak-proof. This ensures that the integrity of the pipe is maintained, and that water pressure is not compromised.

Another key advantage of repair couplings is their versatility. Repair couplings are suitable for use with a wide range of pipe materials, including steel, copper, and plastic, and can even be used to join pipes of different sizes. Repair couplings are also available in a variety of sizes and styles, allowing you to easily find the right coupling for your needs.

Finally, using a repair coupling is also quick and easy. Repair couplings can be installed in minutes, and require no special tools or skills, making them an ideal solution for emergency situations. With a repair coupling, you can quickly and easily repair damaged pipes and get your water supply back up and running.

In conclusion, repair couplings offer a simple, cost-effective, and secure solution for repairing broken pipes. With their versatility, ease of use, and quick installation, it is easy to see why repair couplings are a popular choice for pipe repair.

Maintenance Tips for Repair Couplings

Repair couplings are integral components of any piping system, and when correctly installed, they can provide a secure and reliable connection between two pipes. They are used for a variety of purposes, including repairs and modifications of existing piping systems. When it comes to maintenance, it is important to keep repair couplings in prime condition to ensure that they function properly and keep your pipes and system safe. Here are some tips for proper maintenance of repair couplings:

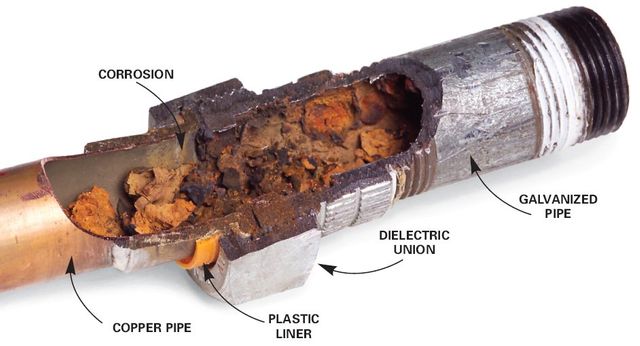

1. Inspect your repair couplings regularly. Make sure to check for signs of damage or corrosion, and replace or repair any faulty parts immediately.

2. Clean the coupling before connecting it to a pipe. This will remove any debris, dirt, or other contaminants that could prevent a proper connection.

3. Make sure the coupling is properly secured. Use the correct tools and techniques to ensure that the coupling is securely fastened and will not come loose.

4. Use the correct lubricant when installing a repair coupling. Many repair couplings require specific lubricants to ensure a proper connection.

5. When replacing or repairing a repair coupling, make sure to use the same type of coupling as before. This will ensure that the connection is secure and reliable.

By following these tips, you can ensure that your repair couplings are in top condition and ready to provide a secure connection between your pipes. Regular maintenance and inspections are essential for keeping your repair couplings functioning properly and your pipes safe.

Troubleshooting Common Issues with Repair Couplings

Repair couplings are an essential part of any plumbing system, providing an easy way to access pipes and repair them when needed. But if you’re new to repair couplings, you may not know how to use them properly or how to troubleshoot common issues. This article will provide an in-depth look at repair couplings and how to use them, as well as how to identify and fix the most common issues.

First, let’s look at the anatomy of a repair coupling. A repair coupling is a fitting that connects two pipes together, allowing for access to the pipe and the ability to repair it without having to replace the entire pipe. Repair couplings come in a variety of sizes and shapes to fit any pipe configuration. Additionally, repair couplings can be made from plastic, brass, or steel, depending on the application.

When it comes to installation, it’s important to make sure the repair coupling is correctly seated and secured. When properly installed, repair couplings should provide a watertight seal. If there are any leaks, it’s likely due to a faulty installation. Additionally, make sure to use the appropriate tools and follow the manufacturer’s instructions for installation.

It’s also important to check for signs of damage or corrosion, as these can weaken the repair coupling and cause leaks. If you see any signs of damage, it’s best to replace the repair coupling. Additionally, it’s important to check for proper orientation of the repair coupling, as this can affect how well it seals.

Finally, it’s important to check the pipes for any obstructions or clogs that could prevent the repair coupling from making a secure connection. If any obstructions are found, they should be removed before installing the repair coupling.

Using repair couplings can be a great way to access and repair pipes without having to replace the entire pipe. However, it’s important to understand how to properly install and use them in order to ensure a secure connection and a watertight seal. Additionally, be sure to check for signs of damage, proper orientation, and any obstructions before installing the repair coupling. Following these simple steps can help ensure your repair couplings are secure and working properly.

FAQs About the How Do You Use A Repair Coupling?

1. What kind of pipe can a repair coupling be used on?

A repair coupling can be used on many different types of pipe, including PVC, ABS, and cast iron.

2. Are repair couplings easy to install?

Yes, repair couplings are very easy to install and can be done in a matter of minutes.

3. Are repair couplings permanent?

Yes, repair couplings are a permanent solution and can be used to repair or join broken pipes.

Conclusion

A repair coupling is a great tool to have on hand for quick fixes to pipes. It can be used to repair a pipe that has been broken, cracked, or worn out. It is easy to install, and its use does not require any special tools or skills. It is also relatively inexpensive and can provide a quick fix to many plumbing problems. With regular maintenance and inspection of pipes, a repair coupling can help to extend the life of the piping system.