What are the 3 main types of plastic pipe?

Benefits of using plastic pipes

Plastic pipes have become increasingly popular in the plumbing industry due to their numerous advantages over traditional metal pipes. Here are some key benefits of using plastic pipes:

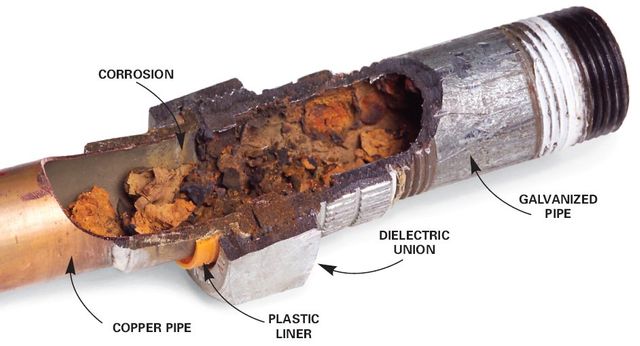

- Durability and longevity: Plastic pipes are highly durable and have a long lifespan, making them a cost-effective choice for plumbing systems. Unlike metal pipes, plastic pipes are resistant to corrosion, rust, and scaling. They can withstand high pressure and are less prone to leaks and cracks, ensuring a reliable and leak-free plumbing system for years to come.

- Lightweight and easy installation: One of the major advantages of plastic pipes is their lightweight nature, which makes them easy to handle and install. Unlike heavy metal pipes, plastic pipes can be easily transported and maneuvered around tight spaces. Additionally, plastic pipes can be joined using various methods such as solvent welding, compression fittings, or push-fit connections, making the installation process quick and hassle-free.

Chemical resistance

Plastic pipes exhibit excellent resistance to chemicals and acids, making them suitable for a wide range of applications. They are not affected by the corrosive properties of certain substances, ensuring the integrity of the plumbing system. This makes plastic pipes an ideal choice for wastewater drainage, industrial applications, and areas with aggressive soil conditions.

- Cost-effective: Compared to metal pipes, plastic pipes are more affordable, making them a cost-effective option for plumbing installations. The lower material and installation costs, combined with the longevity and durability of plastic pipes, make them a wise investment in the long run. Additionally, plastic pipes require minimal maintenance and do not require regular painting or coating like metal pipes.

- Environmentally friendly: Plastic pipes are considered more environmentally friendly compared to metal pipes. They are often made from recycled materials and can be recycled again at the end of their lifespan. Plastic pipes also have a lower carbon footprint during manufacturing and transportation, contributing to a more sustainable plumbing industry.

In summary, the benefits of using plastic pipes in plumbing systems are abundant. Their durability, lightweight nature, chemical resistance, cost-effectiveness, and environmental friendliness make them a preferred choice for various applications. Whether it’s for residential, commercial, or industrial use, plastic pipes offer a reliable and efficient plumbing solution.

Different materials used in plastic pipes

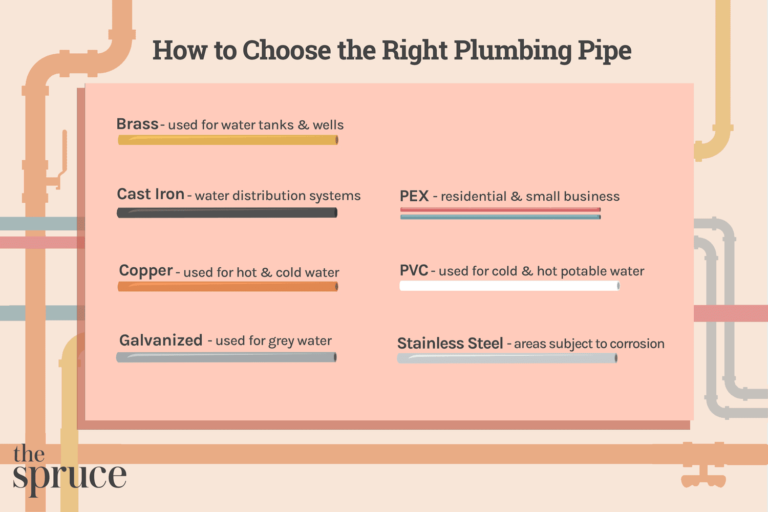

Plastic pipes are made from different materials, each with its own unique properties and characteristics. Understanding the different materials used in plastic pipes can help you choose the most suitable option for your specific plumbing needs. Here are the three main types of plastic pipes commonly used:

- PVC (Polyvinyl Chloride): PVC pipes are the most widely used type of plastic pipes in the plumbing industry. They are made from a combination of vinyl chloride monomer and various additives. PVC pipes are known for their versatility, affordability, and ease of installation. They are commonly used for drainage systems, irrigation, and cold water supply. PVC pipes are available in various sizes and schedules, making them suitable for both residential and commercial applications. They are resistant to acids, alkalis, and corrosion, making them ideal for use in aggressive soil conditions. PVC pipes can withstand high pressure and temperature variations, ensuring a reliable plumbing system.

- HDPE (High-Density Polyethylene): HDPE pipes are made from high-density polyethylene, a thermoplastic material known for its strength and durability. HDPE pipes are commonly used for water supply systems, including potable water, irrigation, and industrial applications. They are resistant to chemicals, UV rays, and environmental stress cracking, making them suitable for both aboveground and underground installations. HDPE pipes are lightweight and flexible, allowing for easy transportation and installation. They have excellent resistance to impact and can withstand harsh weather conditions, making them an ideal choice for outdoor plumbing installations. HDPE pipes have a smooth inner surface, minimizing friction and ensuring efficient water flow.

- PEX (Cross-linked Polyethylene): PEX pipes are made from cross-linked polyethylene, a flexible and durable material. PEX pipes are commonly used for hot and cold water supply systems, including residential and commercial applications. They are highly resistant to scale buildup, freezing, and bursting, making them suitable for both interior and exterior plumbing installations. PEX pipes can be bent and curved without the need for extra fittings, allowing for easy installation in tight spaces. They have a smooth inner surface, reducing friction and pressure loss. PEX pipes also have excellent resistance to chemicals, making them suitable for aggressive water conditions.

In summary, the different materials used in plastic pipes offer a range of properties and characteristics. PVC pipes are versatile and affordable, HDPE pipes are strong and durable, and PEX pipes are flexible and easy to install. Consider the specific requirements of your plumbing system when choosing the most suitable type of plastic pipe.

PVC pipes – characteristics, uses, and advantages

PVC (Polyvinyl Chloride) pipes are widely used in the plumbing industry for their versatility, affordability, and durability. PVC pipes are made from a combination of vinyl chloride monomer and various additives, resulting in a strong and resilient material.

Here are the characteristics, uses, and advantages of PVC pipes:

Characteristics of PVC pipes

- Versatility: PVC pipes are available in various sizes and schedules, making them suitable for a wide range of applications. They can be easily cut, joined, and connected using different methods such as solvent welding, compression fittings, or push-fit connections.

- Resistance: PVC pipes are resistant to acids, alkalis, and corrosion, making them suitable for use in aggressive soil conditions. They can withstand high pressure and temperature variations without compromising their integrity.

- Smooth inner surface: PVC pipes have a smooth inner surface, minimizing friction and pressure loss. This ensures efficient water flow and reduces the risk of clogs and blockages.

- Lightweight: PVC pipes are lightweight, making them easy to handle and install. They can be easily transported and maneuvered around tight spaces, reducing the overall installation time and effort.

PVC pipes have a wide range of uses in plumbing systems, including:

- Drainage systems: PVC pipes are commonly used for wastewater drainage due to their resistance to chemicals and corrosion. They are available in various sizes and configurations, allowing for efficient removal of wastewater.

- Irrigation: PVC pipes are widely used for agricultural and landscape irrigation systems. They can withstand high-pressure water flow and provide excellent resistance to UV rays, ensuring the longevity of the irrigation system.

- Cold water supply: PVC pipes are suitable for cold water supply systems in both residential and commercial buildings. They can handle a wide range of temperatures and are resistant to scaling and corrosion.

Advantages of PVC pipes

- Affordability: PVC pipes are more affordable compared to other types of plastic pipes, making them a cost-effective choice for plumbing installations.

- Durability: PVC pipes have a long lifespan and are resistant to corrosion, rust, and scaling. They require minimal maintenance and offer a reliable plumbing solution.

- Easy installation: PVC pipes are lightweight and easy to handle, allowing for quick and hassle-free installation. They can be cut, joined, and connected using various methods, reducing the overall installation time and effort.

- Chemical resistance: PVC pipes are resistant to acids, alkalis, and other chemicals, making them suitable for a wide range of applications. They can withstand aggressive soil conditions and ensure the integrity of the plumbing system.

FAQS for What are the 3 main types of plastic pipe?

1. What is PVC pipe?

PVC stands for Polyvinyl Chloride. It is a widely used plastic pipe material known for its durability and affordability. PVC pipes are often used for water supply lines, drainage systems, and in some cases, electrical conduit.

2. What is CPVC pipe?

CPVC stands for Chlorinated Polyvinyl Chloride. It is a variation of PVC that is specifically designed for hot water applications. CPVC pipes are used for transporting hot water and can withstand higher temperatures compared to standard PVC pipes.

3. What is PEX pipe?

PEX stands for Cross-linked Polyethylene. PEX pipes are flexible plastic pipes known for their ease of installation. They are commonly used for both hot and cold water supply lines, as well as for radiant floor heating systems.

Conclusion

PVC pipes are a versatile, affordable, and durable option for plumbing systems. Their resistance to chemicals, corrosion, and scaling, combined with their ease of installation, make them a preferred choice for drainage systems, irrigation, and cold water supply. Consider the specific requirements of your plumbing system when choosing PVC pipes for optimal performance and longevity.