What is CPVC material?

Are you wondering what CPVC material is and why it’s gaining popularity? Look no further! In this article, we’ll explore the ins and outs of CPVC, including its properties, uses, and benefits. CPVC stands for chlorinated polyvinyl chloride, which is a thermoplastic material known for its excellent chemical resistance and high-temperature performance. It is commonly used in plumbing and water distribution systems due to its ability to withstand high pressures and temperatures.

With CPVC, you can enjoy peace of mind knowing that your plumbing system is durable, reliable, and resistant to corrosion. Its high-impact strength and low cost also make it a preferred choice in various industries like manufacturing, automotive, and electrical.

Whether you’re a homeowner, a DIY enthusiast, or a professional in the construction industry, understanding CPVC material can be valuable. So, let’s dive deep into the world of CPVC and unlock its amazing properties and applications. Get ready to explore the versatile world of CPVC and discover why it’s becoming the go-to material for many projects.

Characteristics and properties of CPVC material

CPVC material possesses a unique set of characteristics and properties that make it suitable for a wide range of applications. One of its key properties is its excellent chemical resistance, which allows it to withstand exposure to various acids, alkalis, and other corrosive substances. This makes CPVC an ideal choice for plumbing systems that come into contact with aggressive chemicals.

In addition to its chemical resistance, CPVC also exhibits high-temperature performance. It can withstand temperatures of up to 200°F (93°C), making it suitable for hot water distribution systems and industrial applications that involve high-temperature fluids. Its ability to handle high pressures and temperatures without deforming or cracking makes CPVC a reliable and long-lasting material option.

Furthermore, CPVC material has exceptional fire resistance properties, making it self-extinguishing when exposed to flames. This fire resistance property adds an extra layer of safety to buildings and structures where CPVC is used. Additionally, CPVC is lightweight, easy to handle, and has low thermal conductivity, reducing heat loss in plumbing systems.

Overall, the combination of chemical resistance, high-temperature performance, fire resistance, and ease of handling makes CPVC material a top choice for various applications in construction, plumbing, and other industries.

Applications of CPVC material

- CPVC material finds extensive use in a wide range of applications across different industries. One of its primary applications is in plumbing systems, where it is used for hot and cold water distribution, as well as for the transportation of chemicals. The exceptional chemical resistance of CPVC ensures that the plumbing system remains intact and reliable for an extended period, even when exposed to aggressive fluids.

- Apart from plumbing, CPVC material is also used in industrial applications that require the handling of corrosive chemicals and high-temperature fluids. It is commonly used in chemical processing plants, where it serves as a reliable and cost-effective solution for transporting various chemicals. CPVC pipes and fittings are also used in the automotive industry for coolant and fuel systems, thanks to their ability to withstand high temperatures.

- Furthermore, CPVC material is utilized in the electrical industry for cable insulation, junction boxes, and conduit systems. Its excellent fire resistance properties and high dielectric strength make it a safe and reliable choice for electrical applications. Additionally, CPVC is used in the manufacturing industry for the production of pipes, tubes, and profiles due to its ease of processing and cost-effectiveness.

- The versatility of CPVC material is evident through its applications in different industries, highlighting its reliability, durability, and adaptability to various environments and requirements.

Advantages and disadvantages of CPVC material

Like any material, CPVC has its share of advantages and disadvantages that should be considered before choosing it for a project. Understanding these pros and cons can help you make an informed decision and ensure that CPVC aligns with your specific needs.

Advantages of CPVC material:

- Chemical resistance: CPVC has excellent resistance to a wide range of chemicals, making it suitable for applications that involve exposure to corrosive substances.

- High-temperature performance: CPVC can handle high temperatures of up to 200°F (93°C) without deforming or cracking, making it suitable for hot water distribution systems and industrial applications.

- Fire resistance: CPVC is self-extinguishing, meaning it does not support combustion. This property adds an extra layer of safety to buildings and structures.

- Low thermal conductivity: CPVC has low thermal conductivity, reducing heat loss in plumbing systems and making it energy-efficient.

- Cost-effective: CPVC is a cost-effective material option when compared to other alternatives like copper or stainless steel.

Disadvantages of CPVC material:

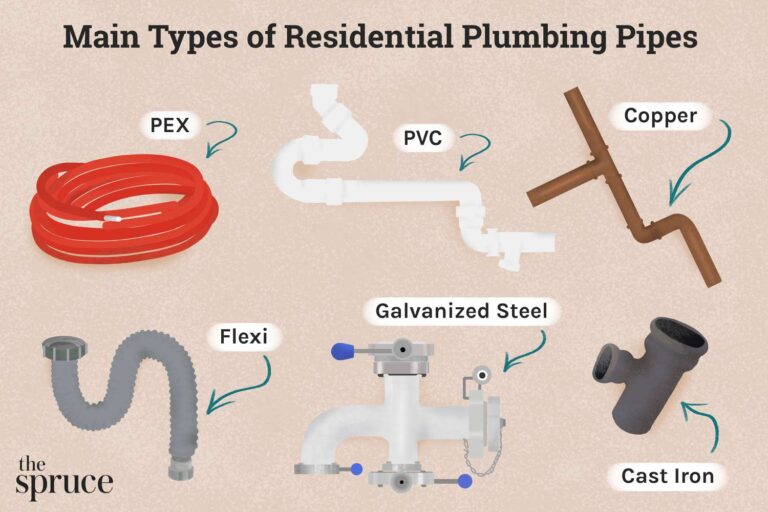

- Limited temperature range: While CPVC can handle high temperatures, it has a lower maximum temperature limit compared to materials like metal or PEX.

- Not suitable for some solvents: Certain solvents or chemicals may cause degradation or swelling of CPVC, limiting its use in specific applications.

- Requires special solvent cement: Joining CPVC pipes and fittings requires the use of a specific solvent cement, which may require additional care and equipment.

- Susceptible to UV degradation: CPVC is not suitable for outdoor applications or prolonged exposure to sunlight, as UV rays can degrade the material over time.

Understanding the advantages and disadvantages of CPVC material allows you to evaluate whether it is the right choice for your specific project or application.

CPVC vs. PVC: What’s the difference?

CPVC and PVC are often mentioned together, but they are not the same material. While both are forms of polyvinyl chloride, there are distinct differences between them, specifically in terms of their chemical composition and properties.

- The main difference between CPVC and PVC lies in the level of chlorination. CPVC is created by adding chlorine to PVC, which results in a more robust and heat-resistant material. The addition of chlorine atoms makes CPVC more resistant to chemical corrosion, higher temperatures, and pressure.

- Another significant difference is the maximum temperature that each material can handle. PVC has a lower maximum temperature limit of around 140°F (60°C), while CPVC can withstand temperatures of up to 200°F (93°C). This higher temperature resistance makes CPVC suitable for hot water distribution systems and industrial applications that involve high-temperature fluids.

- Additionally, CPVC has a higher impact strength than PVC, making it less prone to cracking or breaking when exposed to physical stress or impact. This characteristic makes CPVC a more durable and reliable choice for applications where strength and longevity are crucial.

- It’s important to note that while CPVC and PVC can have similar appearances, they are not interchangeable. CPVC should be used in applications that require its specific properties, such as high-temperature resistance and chemical resistance, while PVC is suitable for applications that do not involve high temperatures or aggressive chemicals.

Manufacturing process of CPVC material

The manufacturing process of CPVC material involves several steps to transform PVC into a more robust and heat-resistant material. Let’s take a closer look at the key stages involved in the production of CPVC.

- Chlorination: The first step in the manufacturing process is chlorination. PVC resin is mixed with chlorine gas, which reacts with the polymer chains to replace some of the hydrogen atoms with chlorine atoms. This chlorination process results in the formation of CPVC.

- Cooling and grinding: After chlorination, the CPVC compound is cooled and then ground into a fine powder. This powder form allows for easier handling and processing during the subsequent stages.

- Extrusion: The CPVC powder is then fed into an extruder, where it is heated and melted. The molten CPVC is then forced through a die, which shapes it into the desired form, such as pipes, fittings, or sheets.

- Cooling and sizing: Once the CPVC has been extruded into its desired shape, it goes through a cooling process to solidify and stabilize its structure. The cooled CPVC products are then cut or sized according to the required dimensions.

- Quality control: Throughout the manufacturing process, quality control measures are implemented to ensure that the CPVC material meets the required specifications. This includes testing for chemical resistance, temperature resistance, and impact strength, among other properties.

The manufacturing process of CPVC material requires precision and adherence to strict quality control standards to produce a reliable and high-performance material.

Common uses of CPVC material in construction and plumbing

CPVC material finds widespread use in the construction and plumbing industries due to its exceptional properties and performance. Let’s explore some of the common applications of CPVC in these fields.

- Plumbing systems: CPVC is widely used in plumbing systems for both residential and commercial buildings. It is used for hot and cold water distribution, as well as for transporting chemicals. CPVC pipes and fittings provide a durable and reliable solution that can withstand high pressures, temperatures, and corrosive substances.

- Fire sprinkler systems: CPVC is commonly used in fire sprinkler systems due to its fire resistance properties. It can handle high temperatures without deforming or melting, ensuring that the sprinkler system remains functional in the event of a fire.

- Industrial piping: CPVC is utilized in various industrial applications that involve the handling of corrosive chemicals and high-temperature fluids. It is commonly used in chemical processing plants, oil refineries, and manufacturing facilities.

- Cooling systems: CPVC pipes and fittings are used in cooling systems, including air conditioning and refrigeration. The high-temperature resistance of CPVC allows it to handle the demands of cooling fluids and maintain system efficiency.

- Water treatment plants: CPVC material is used in water treatment plants for the transportation of chemicals and treated water. Its chemical resistance ensures that the pipes and fittings remain intact and reliable, even when exposed to aggressive substances.

The versatility and reliability of CPVC make it a preferred choice in construction and plumbing applications where durability, chemical resistance, and high-temperature performance are essential.

Maintenance and care of CPVC material

- While CPVC material is known for its durability and long-lasting performance, proper maintenance and care can further extend its lifespan and ensure optimal performance. Here are some maintenance tips for CPVC:

- Regular inspections: Periodically inspect your CPVC plumbing system or other CPVC applications for any signs of leaks, cracks, or damage. Early detection can prevent further issues and ensure timely repairs.

- Avoid harsh chemicals: While CPVC is resistant to many chemicals, it is still advisable to avoid using harsh solvents or chemicals that may cause degradation or swelling of the material. Stick to recommended cleaning agents and avoid abrasive tools that may scratch the surface of CPVC.

- Prevent freezing: In areas where freezing temperatures occur, take precautions to prevent CPVC pipes from freezing. Insulate exposed pipes and ensure proper insulation in areas where freezing is a concern.

- Proper installation: Ensure that CPVC pipes and fittings are installed correctly, following the manufacturer’s guidelines and using the appropriate solvent cement. Improper installation can lead to leaks or failures in the plumbing system.

- Regular cleaning: Clean CPVC surfaces regularly to remove any dirt, debris, or mineral deposits that may accumulate over time. Use a mild detergent or cleaner and a soft cloth or sponge to avoid scratching the surface.

By following these maintenance tips, you can ensure that your CPVC material remains in optimal condition and continues to deliver reliable performance for years to come.

Safety considerations when working with CPVC material

When working with CPVC material, it is important to prioritize safety to avoid any potential hazards. Here are some safety considerations to keep in mind:

- Proper ventilation: Ensure that the work area is well-ventilated to prevent the buildup of fumes or vapors that may be released during the installation or fabrication process. Use fans or open windows to improve air circulation.

- Protective equipment: Wear appropriate personal protective equipment (PPE) when working with CPVC, including gloves, safety glasses or goggles, and respiratory protection if necessary. PPE can help prevent direct contact with the material and protect against potential hazards.

- Follow manufacturer guidelines: Always follow the manufacturer’s guidelines and instructions when handling, cutting, or joining CPVC material. This includes using the recommended solvent cement and following proper installation techniques.

- Avoid open flames: CPVC is self-extinguishing, but it is still advisable to avoid open flames or sources of ignition when working with the material. Keep flammable materials away from the work area and use caution when using heat sources.

- Disposal: Dispose of CPVC waste properly according to local regulations and guidelines. Do not burn or incinerate CPVC material, as it can release harmful gases.

By adhering to these safety considerations, you can minimize the risks associated with working with CPVC material and ensure a safe working environment.

FAQS for What is CPVC material?

1. What is CPVC, and how does it differ from PVC?

CPVC stands for Chlorinated Polyvinyl Chloride. It is a thermoplastic material and a variation of PVC (Polyvinyl Chloride). The primary difference is that CPVC contains chlorine atoms, which make it suitable for handling hot water and higher temperatures.

2. What are the key advantages of CPVC over PVC?

CPVC offers superior heat resistance, making it suitable for hot water applications. It is also more chemically resistant than PVC and has a smoother interior surface, reducing the likelihood of scale buildup. Additionally, CPVC is less likely to corrode or degrade when exposed to certain chemicals.

3. What are common applications for CPVC pipes and fittings?

CPVC is commonly used in residential and commercial plumbing systems for hot and cold water supply lines. It is also utilized in industrial applications, including chemical processing, as well as in the fire sprinkler industry.

Conclusion and final thoughts on CPVC material

CPVC material is a versatile and reliable thermoplastic that offers excellent chemical resistance, high-temperature performance, and fire resistance. Its use in various industries, including construction, plumbing, manufacturing, automotive, and electrical, highlights its wide range of applications and benefits.

Understanding the characteristics, properties, and applications of CPVC material allows homeowners, DIY enthusiasts, and professionals in the construction industry to make informed decisions when it comes to selecting the right material for their projects. By choosing CPVC, you can enjoy the peace of mind that comes with a durable, reliable, and corrosion-resistant material.

Whether you’re looking to upgrade your plumbing system, embark on a DIY project, or explore new material options for your industry, CPVC material is worth considering. Its outstanding performance, cost-effectiveness, and ease of use make it a go-to choice for many applications.

So, embrace the versatility of CPVC material and unlock its incredible potential in your next project. With CPVC, you can build with confidence, knowing that you have chosen a material that combines functionality, durability, and reliability.