What Is Leakage Pressure?

Leak pressure is a term used to describe the pressure that results from a fluid (such as air, water, or steam) passing through a small hole or crack in a pipe, container, or other structure. Leak pressure is important because it can be used to detect and measure the amount of leakage from a pipe or other structure. It can also be used to identify potential weak points in the pipe or structure that may need to be repaired or replaced. Leak pressure is a critical factor in ensuring the safety and reliability of any system that relies on pressurized fluids.

Definition of Leak Pressure

Leak pressure is a measure of the amount of pressure applied to a seal or pipe. It is the amount of pressure required to cause a leak in a system, such as a pipe or seal. By understanding leak pressure, engineers and technicians can identify and fix problems with seals or pipes before they cause significant damage.

Leak pressure is the pressure at which a seal or pipe leaks. It is usually measured in the same units as the system pressure and is usually expressed in bar or psi. Leak pressure is usually higher than the system pressure, as some of the pressure is lost due to friction and other factors. It is important to understand the leak pressure of a system so that it can be monitored and maintained at an acceptable level.

Leak pressure testing is a method used to measure the pressure of a system to determine its leak pressure. This can be done by measuring the pressure drop in a system over time. Leak pressure testing can also be used to identify weak points in a system and identify potential leak sources.

Leak pressure is an important factor in the design and maintenance of systems. Understanding the leak pressure of a system can help to ensure that it is functioning properly and can help to identify potential problems before they become serious. By monitoring and maintaining leak pressure, engineers and technicians can ensure that systems are safe and reliable.

Causes of Leak Pressure

Leaks in a system can be caused by a variety of factors, from worn seals to corroded components. When a system experiences a leak, the pressure within the system drops and air starts to enter the system. This is known as leak pressure. Leak pressure can occur in any system, from gas lines to plumbing fixtures. It is important to identify and repair any leaks as soon as possible to prevent further damage and safety risks.

Leaks can be caused by a variety of problems, including worn seals, damaged components, corrosion, defective parts, and improper installation. Seals, such as O-rings, are designed to prevent air and liquids from escaping the system and can become worn over time, leading to a leak. Corrosion can weaken components and cause them to break, resulting in a leak. Defective parts can also cause a leak and should be replaced immediately. Incorrect installation of components can also lead to a leak, as components must be properly placed for the system to function correctly.

Leak pressure is a serious issue that can cause damage to a system and can be a safety hazard. It is important to identify and repair any leaks as soon as possible to prevent further damage and safety risks. Regular maintenance and inspections can help detect potential leaks before they become a problem.

Signs of Leak Pressure

Leaks can be a major issue when it comes to plumbing, and leak pressure is something that can cause significant damage to a building. Leak pressure is the pressure that is present in a pipe when the water that is flowing through it is greater than the pressure that is in the pipe itself. This can cause the pipe to burst, leading to costly repairs. Knowing the signs of leak pressure can help you identify the issue before it becomes too severe.

One of the most common signs of leak pressure is a decrease in water pressure. If you notice that the water pressure in your home or business is lower than it usually is, it could be a sign that there is water leaking from a pipe somewhere. The longer the leak goes undetected, the more damage it can do.

You may also notice a damp spot or pool of water somewhere in the building. This could be a sign of a leak. You may also notice an increase in your water bill, as the excess water that is leaking will not be accurately accounted for in your bill.

Furthermore, if you can hear a hissing sound coming from the walls, it could be an indication of a gas leak. If this is the case, it is important to contact a professional plumber immediately, as gas leaks can be very dangerous.

By keeping an eye out for these signs, you can ensure that any leak pressure is identified quickly and dealt with appropriately. Leak pressure can cause significant damage, so it is important to address any issues as early as possible.

Measuring Leak Pressure

Leak pressure is a crucial factor in the proper functioning of a variety of systems, from plumbing systems to industrial machinery. It is the pressure at which water, air, or other liquids are allowed to escape from a system. Measuring the leak pressure in a system can help identify potential problems or weaknesses in the system, and it can be used to develop a strategy to prevent further damage or loss. It is important to measure the leak pressure on time to ensure the safety and reliability of the system.

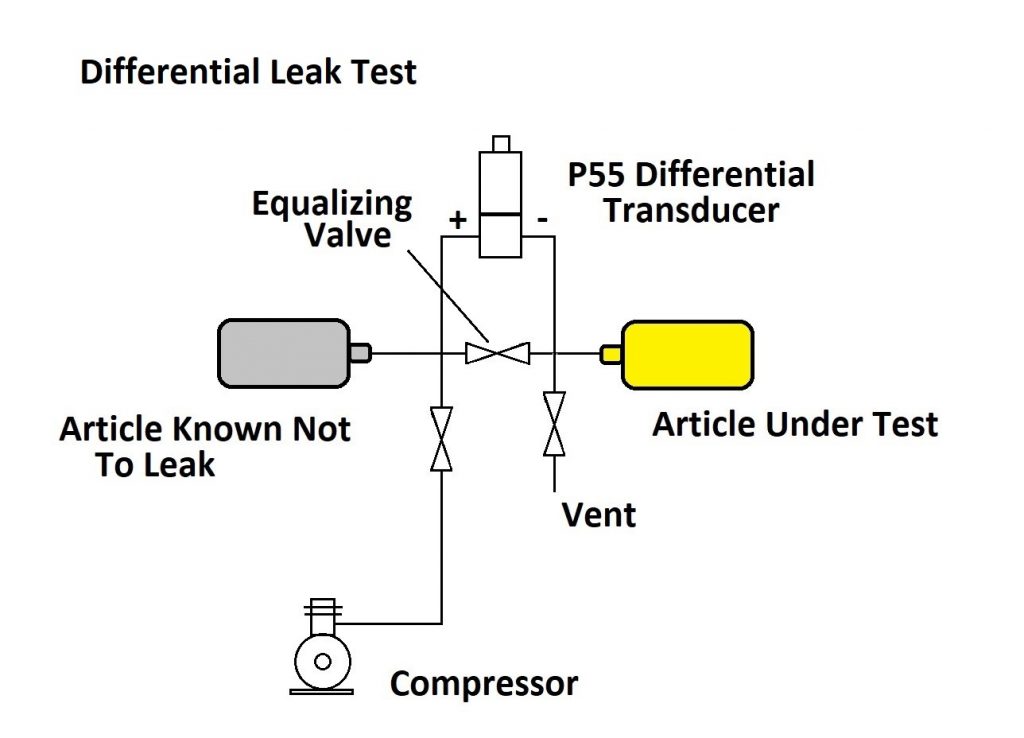

Measuring leak pressure involves the use of specialized equipment, such as pressure gauges, pressure transducers, and pressure sensors. These devices are used to measure the amount of pressure present in the system, and they can also indicate any changes in the pressure over time. Additionally, they can be used to detect any leaks in the system, and they can help identify the source of any leaks.

When measuring leak pressure, it is important to take into account any environmental factors that could affect the results. For example, if the system is located in an area with high humidity, the readings may be inaccurate. Additionally, the pressure gauges used should be calibrated regularly to ensure accuracy. Finally, it is important to properly maintain all of the equipment used to measure leak pressure to ensure accurate readings.

By measuring and monitoring leak pressure, it is possible to identify potential problems in a system and take steps to prevent further damage or loss. It is important to use the right equipment and take into account any environmental factors to ensure accurate readings. By properly monitoring leak pressure, it is possible to protect the system and ensure its proper functioning.

Preventing Leak Pressure

Leak pressure is an important concept to understand when it comes to maintaining the integrity of a system. It is the pressure that exists in a system due to a leak or a crack in the system itself. Leak pressure can cause serious damage to a system and can be costly to repair. Fortunately, there are ways to prevent leak pressure from occurring.

The most effective way to prevent leak pressure is to regularly check and inspect the system for any flaws or cracks. This can be done with regular inspections as well as with the use of pressure testing equipment. Pressure testing equipment is designed to detect any leaks in the system and alert the operator to any potential problems.

Another way to prevent leak pressure is to use the right sealing materials when installing the system. Sealing materials are designed to create a tight seal around the system that prevents any leaks from occurring. It is important to choose the right type of sealing material for the specific application to ensure the best protection against leaks.

Finally, it is important to use the right lubricants when installing a system. Lubricants are designed to provide an additional layer of protection against leaks, as they are designed to fill in any gaps and keep the system sealed. The right lubricant also helps to increase the system’s life span and maintain its integrity.

By implementing these preventive measures, leak pressure can be avoided and the integrity of the system can be maintained. Regular inspections and pressure tests are essential for any system, and using the right sealing materials and lubricants can help ensure that any leaks are avoided.

Fixing Leak Pressure Issues

Leaks in pipes and other plumbing systems can cause serious problems to your home or business. Leaks can cause damage to property, waste water and energy, and create other safety hazards. Leak pressure is the amount of force that is applied to a pipe or plumbing system from the water or other liquid inside it. This pressure can be measured in pounds per square inch (psi), and it is important to understand how to identify and fix any potential problems with leak pressure.

There are a few different methods of testing and fixing leak pressure issues. The most common method is to use a pressure gauge. These gauges measure the amount of force that is being applied to the pipe or plumbing system. If the pressure is too high, then the pipe or plumbing system may need to be repaired or replaced. Other methods of testing and fixing leak pressure issues include using a specialized camera to find any potential cracks or breaks in the pipe or plumbing system, as well as using a specialized sealant to stop any existing leaks.

In addition to testing and fixing leak pressure issues, it is also important to take preventative measures to help avoid them in the future. This includes regularly inspecting pipes and plumbing systems, fixing any identified issues, and ensuring that the pipes and plumbing systems are properly maintained. Taking these steps can help to ensure that any potential leak pressure issues are identified and fixed quickly before they become a major problem.

FAQs About the What Is Leak Pressure?

Q: What is Leak Pressure?

A: Leak pressure is the pressure at which a fluid or gas escapes from a container, pipe, valve, or other system. It is usually measured in pounds per square inch (PSI).

Q: How is Leak Pressure Measured?

A: Leak pressure is measured with a pressure gauge or a differential pressure gauge. The pressure gauge measures the amount of pressure at which the fluid or gas is escaping from the system.

Q: What is the Difference between Leak Pressure and Operating Pressure?

A: The difference between leak pressure and operating pressure is that operating pressure is the pressure under which the system is designed to operate, while leak pressure is the pressure at which the fluid or gas escapes from the system.

Conclusion

Leak pressure is the pressure that is required to keep a fluid or gas contained within a system. It is the difference between the pressure inside and outside the system. Leak pressure is important to ensure that a system can function properly without any leakages. If the leak pressure is too low, then it can lead to leaks and other issues. On the other hand, if the leak pressure is too high, then it can cause damage to the system and its components. Therefore, it is important to set the leak pressure to the right level for the system to work as intended.