What Is PVC Plumbing Called?

PVC plumbing is a type of plumbing system that uses polyvinyl chloride (PVC) pipes and fittings to connect water supply lines, drains, and other parts of the plumbing system. PVC is a strong, rigid, lightweight, and durable material that is ideal for plumbing applications. PVC plumbing is also known as plastic plumbing, polyvinyl chloride plumbing, or simply PVC piping. PVC pipes and fittings are available in a variety of sizes and shapes, allowing for a wide range of applications in both residential and commercial plumbing systems. PVC plumbing is most commonly used for drain, waste, and vent (DWV) systems in homes and businesses.

Overview of PVC Plumbing

PVC (polyvinyl chloride) plumbing is a type of plastic piping used in residential and commercial plumbing applications. PVC pipes are strong, lightweight, and resistant to corrosion and wear, and they are an affordable option for plumbing projects. They are also easy to install and require fewer fittings than other types of pipe. PVC plumbing is often used for drain, waste, and vent (DWV) systems, water supply lines, and irrigation systems.

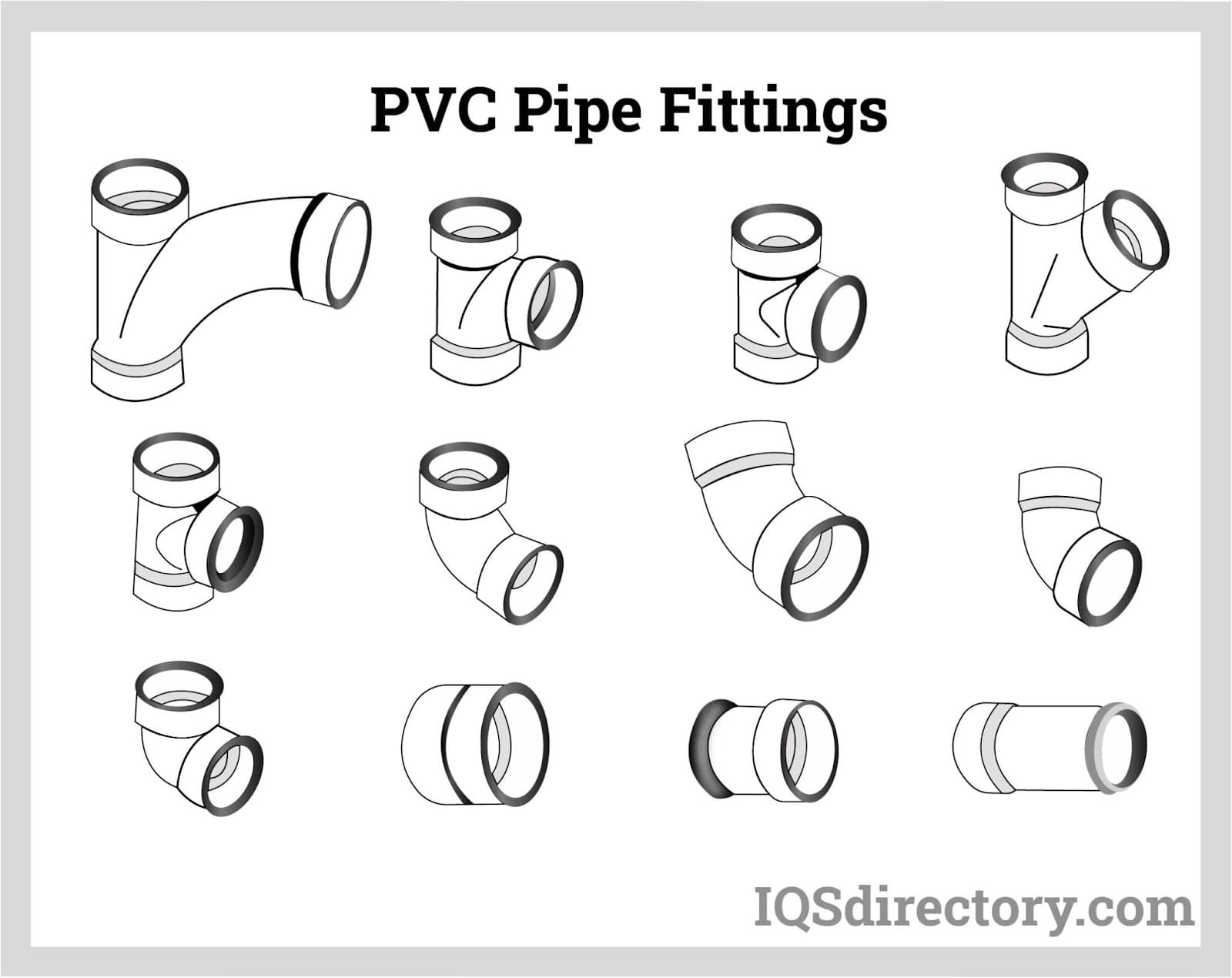

PVC pipes are joined together using a variety of fittings and connectors, such as elbows, couplings, adapters, and unions. These fittings are available in a variety of sizes and shapes, and they can be used to create a secure seal between pipes. PVC pipes can also be connected to other types of piping using transition fittings.

PVC plumbing offers a number of advantages over other types of piping, including its durability, affordability, and ease of installation. It is also resistant to chemical corrosion, temperature changes, and is unaffected by ultraviolet light. It is also non-toxic, making it safe for use in drinking water applications.

Due to its many advantages, PVC plumbing is a popular choice for plumbing projects. It is used in a wide range of residential and commercial applications, including drain, waste, and vent systems, water supply lines, and irrigation systems. It is a reliable and cost-effective option that can provide many years of trouble-free service.

Advantages of Using PVC for Plumbing

PVC, or polyvinyl chloride, is an increasingly popular material used in home plumbing systems. It has a number of advantages over traditional materials, such as copper and galvanized steel, which make it a great choice for those looking to save money and time on plumbing repairs. PVC is lightweight, corrosion-resistant, and can be easily installed. It’s also non-toxic, which makes it safe for drinking water. In addition, PVC plumbing is much more affordable than other types of plumbing, and it requires less maintenance. PVC plumbing is also much more durable than other materials, making it an ideal choice for those who want to ensure their plumbing lasts a long time. PVC is also easier to clean and is more resistant to damage from the elements. Finally, it’s less prone to leaking and bursting, making it a more reliable option for plumbing systems. All these advantages make PVC an ideal choice for those looking to make their plumbing system more efficient and reliable.

Disadvantages of Using PVC for Plumbing

PVC (Polyvinyl Chloride) is a popular choice for plumbing pipes, but it’s not without its flaws. Although PVC is durable, lightweight, and inexpensive, it has several drawbacks that should be considered before using it. PVC is not as flexible as other materials, making it difficult to install in tight spaces. It is also prone to cracking under pressure and is not fire-resistant. Additionally, the plasticizers used to soften PVC pipes can leach into the water, creating a health hazard. PVC is also difficult to repair and is not easily recyclable in most areas. While PVC is an affordable and reliable material for plumbing, it is important to weigh its drawbacks against its advantages to make an informed decision.

Common Applications of PVC Plumbing

PVC plumbing is a versatile material that is used in many industries. Its most common applications are in the construction, plumbing, and heating industries. PVC is a lightweight, durable, and cost-effective material that is easy to work with and install. It is often used to make a wide variety of plumbing supplies, including pipes, fittings, valves, and adaptors. It is also used to make drain pipes, water supply lines, and other plumbing components. PVC plumbing is also used in certain industrial applications such as food processing, chemical processing, and wastewater treatment.

Because of its durability and low cost, PVC is often the preferred plumbing material for many residential and commercial applications. It is resistant to corrosion, does not require special maintenance, and is easy to install. PVC pipes are also available in various sizes, making it a good choice for a variety of plumbing projects. PVC fittings are also available in various shapes and sizes, making them ideal for connecting different types of pipe and creating complex plumbing systems.

Overall, PVC plumbing is an excellent choice for a variety of applications. It is a cost-effective, durable, and easy to install material that can be used in a variety of residential and commercial plumbing projects. It is also resistant to corrosion, making it a good choice for applications that require a long-lasting and reliable plumbing system.

Installation Process for PVC Plumbing

PVC plumbing is a great solution for modern plumbing needs. It is a cost-effective and durable material for your home’s plumbing system. To ensure that your plumbing system functions properly and lasts for many years, it is important to understand the installation process for PVC plumbing.

The installation process for PVC plumbing starts with the selection of the correct pipe size and type. The pipe size and type should be based on the application and the local building codes. If the pipes are too small, they can be easily clogged and the water pressure can be inadequate. If the pipes are too large, the water pressure can be too strong and the flow rate can be too high.

After selecting the correct pipe size and type, the next step is to cut and prepare the pipes. PVC pipes can be cut with a handsaw or power saw, and they must be cut to the exact length and diameter required. All ends of the pipes must be cut at a 45-degree angle, or the pipe will not fit properly.

The next step is to join the pipes together with fittings. The most common type of fittings for PVC plumbing are elbows, tees, and couplings. They must be carefully selected and connected to ensure a leak-free connection.

Finally, the installation process requires that the pipes be tested for leaks. Pipe testing can be done using a variety of methods including pressure testing, dye testing, and infrared testing.

The installation process for PVC plumbing is relatively straightforward and can be completed in just a few steps. With proper selection of pipe size and type, careful cutting and preparation of the pipes, and the correct fittings, your PVC plumbing system should last for many years.

Alternatives to PVC Plumbing

PVC (polyvinyl chloride) plumbing is a popular choice for many home and business owners due to its affordability and durability. But it’s not the only option available. There are a variety of other materials used for plumbing, each with its own advantages and disadvantages. From copper and cast iron to brass and lead, the list of alternatives is extensive.

Copper is a popular choice and is often seen as a more expensive but more reliable material. It is also resistant to corrosion and is easy to work with. Cast iron is a heavy-duty option that’s both strong and long-lasting. Brass is also a great option, known for its resistance to corrosion and ability to stand up to high temperatures. Lead plumbing is another option, but is becoming less popular due to concerns about contamination.

The best material for a plumbing project depends on the particular needs of the project. Factors such as cost, durability, and installation requirements should all be taken into consideration when making a decision. In the end, it’s important to choose the material that will best suit your particular needs.

FAQs About the What Is PVC Plumbing Called?

1. What types of plumbing are typically made out of PVC?

A. PVC is most commonly used for drain, waste, and vent (DWV) piping applications. It is also used for water supply lines, irrigation systems, and pool and spa systems.

2. What are the benefits of using PVC piping?

A. PVC piping is lightweight, strong, and cost-effective. It is also corrosion-resistant and easy to install. Additionally, it does not require soldering or glue, making it simple to work with.

3. How do I know if I have PVC piping in my home?

A. You can usually identify PVC piping by its characteristic white or light gray color. It will also have a distinct plastic smell when cut into. Additionally, you can look for a marking on the pipe that reads “PVC” or “PVC DWV”.

Conclusion

PVC plumbing is a type of plastic pipe used in residential and commercial construction. It is strong, durable, and easy to install, making it an attractive choice for many plumbing applications. PVC plumbing is also cost-effective, which makes it a popular option for those looking to save money while still getting quality plumbing. PVC plumbing is also known as polyvinyl chloride plumbing, or PVC piping.