What is PVC quality?

Welcome to our guide on PVC quality! In this article, we will explore the ins and outs of PVC and dive into what determines its quality. Whether you are a contractor, homeowner, or simply curious about PVC, understanding its quality is essential for making informed decisions.

Polyvinyl chloride, or PVC, is a versatile material used in various industries, particularly in construction. Its widespread usage is credited to its durability, cost-effectiveness, and resistance to corrosion and weathering. However, not all PVC is created equal, and it’s crucial to differentiate between poor and high-quality options.

When it comes to PVC quality, several factors come into play, such as the grade of raw materials used, manufacturing processes, and adherence to industry standards. Furthermore, reliable PVC suppliers and manufacturers follow rigorous quality control measures to ensure the PVC’s performance and longevity.

Throughout this article, we will delve into these factors in detail and provide insights on how to identify PVC of superior quality. So, whether you are looking for PVC piping, flooring, or any other PVC product, this guide will equip you with the knowledge to make the best choices for your needs. Stay tuned!

Understanding PVC and its properties

- PVC, or polyvinyl chloride, is a synthetic plastic polymer that is widely used in various industries due to its versatility and durability. It is created through the polymerization of vinyl chloride monomers, resulting in a rigid or flexible material, depending on the additives used during the manufacturing process.

- One of the key properties of PVC is its excellent resistance to corrosion, chemicals, and weathering. This makes it an ideal material for applications that require long-term durability, such as pipes, fittings, and electrical insulation. Additionally, PVC is known for its flame retardant properties, making it a safe choice for construction and other industries.

- The versatility of PVC extends to its ability to be manufactured in different forms, including rigid PVC, flexible PVC, and PVC foam. Each form has its specific properties and applications. For example, rigid PVC is commonly used in construction for pipes, windows, and doors, while flexible PVC is used for electrical cables, flooring, and medical devices.

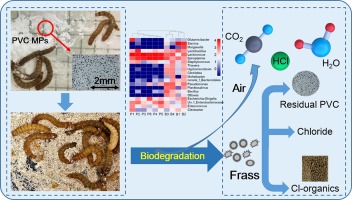

- Despite its many advantages, PVC also has certain limitations. For instance, it can become brittle in cold temperatures and may release toxic gases when burned at high temperatures. However, these limitations can be mitigated by using high-quality PVC and proper installation techniques.

In the next section, we will explore the importance of quality in PVC products and how it can impact their performance and longevity.

Importance of quality in PVC products

- When it comes to PVC products, quality is of utmost importance. High-quality PVC not only ensures the durability and longevity of the product but also guarantees its safe usage. On the other hand, low-quality PVC can lead to a range of issues, including premature failure, increased maintenance costs, and potential health hazards.

- One of the primary factors that determine the quality of PVC products is the grade of raw materials used during the manufacturing process. High-quality PVC is made from virgin PVC resin, which is derived from ethylene or propylene. Virgin PVC resin offers better performance and longevity compared to recycled or lower-grade materials.

- Another critical aspect of PVC quality is the manufacturing process itself. Reputable PVC manufacturers follow strict quality control measures to ensure that the PVC products meet the required standards and specifications. This includes proper blending of additives, precise calibration of equipment, and regular testing of samples to verify their quality.

- In addition to the raw materials and manufacturing process, adherence to industry standards is also crucial for PVC quality. Various organizations, such as ASTM International and the International Organization for Standardization (ISO), have established standards for PVC products to ensure their performance, safety, and environmental sustainability. When choosing PVC products, it is essential to look for certifications and compliance with these standards.

- By investing in high-quality PVC products, you can enjoy several benefits. Firstly, they offer superior durability, reducing the need for frequent replacements and repairs. This not only saves money but also minimizes disruption to your projects or daily life. Secondly, high-quality PVC products are less likely to release harmful chemicals or toxins, ensuring the safety of users and the environment.

In the next section, we will explore the testing and standards for PVC quality, helping you understand how to evaluate the quality of PVC products effectively.

Testing and standards for PVC quality

- To ensure the quality and performance of PVC products, rigorous testing is conducted throughout the manufacturing process. These tests assess various properties of the PVC, such as tensile strength, flexibility, impact resistance, and chemical resistance.

- One of the common tests conducted on PVC products is the tensile strength test. This test measures the amount of force required to stretch the PVC material until it breaks. High-quality PVC should have a high tensile strength, indicating its ability to withstand external forces and stresses.

- Another important test is the flexibility test, which evaluates the PVC’s ability to bend without cracking or breaking. Flexible PVC products, such as electrical cables or hoses, should exhibit good flexibility while maintaining their integrity.

- Chemical resistance is another crucial property to consider, especially for PVC products used in corrosive environments or with exposure to chemicals. The PVC should be tested for its resistance to specific chemicals or substances that it may come into contact with during its intended usage.

- In addition to these physical and chemical tests, PVC products are also assessed for their compliance with industry standards and specifications. These standards cover various aspects, such as dimensions, tolerances, color consistency, and environmental impact.

- When evaluating the quality of PVC products, it is essential to look for certifications or markings indicating compliance with relevant standards. These certifications provide assurance that the PVC products have undergone rigorous testing and meet the required quality criteria.

In the next section, we will discuss common PVC quality issues and how to identify them, enabling you to make informed decisions when purchasing PVC products.

Common PVC quality issues and how to identify them

- Despite the overall reliability and durability of PVC, there can be certain quality issues that may arise in PVC products. Identifying these issues early on can help you avoid potential problems and ensure the longevity of the PVC products you purchase.

- One common quality issue is the presence of impurities or contaminants in the PVC. These impurities can affect the PVC’s performance and may lead to reduced strength, flexibility, or chemical resistance. While it may be challenging to identify impurities visually, choosing PVC products from reputable manufacturers can minimize the risk of such issues.

- Another quality issue to watch out for is poor dimensional stability. PVC products with poor dimensional stability may warp, shrink, or expand when exposed to temperature changes or moisture. This can lead to fitting issues, leakage, or compromised performance. To assess dimensional stability, it is essential to check the manufacturer’s specifications and follow proper installation guidelines.

- Surface defects, such as scratches, dents, or bubbles, can also indicate poor PVC quality. While minor surface defects may not affect the performance of the PVC product significantly, extensive or severe defects can compromise its integrity. Thoroughly inspecting PVC products before installation or use can help identify any visible surface defects.

- Additionally, poor weldability is another quality issue that may occur in PVC products. Weldability refers to the ability of PVC components to be joined together using heat fusion or solvent welding methods. If the PVC does not exhibit good weldability, it can result in weak or unreliable joints. To ensure proper weldability, it is important to follow the manufacturer’s recommendations and use compatible welding techniques.

By being aware of these common PVC quality issues and knowing how to identify them, you can make informed decisions when selecting PVC products for your specific needs. In the next section, we will explore the quality control measures implemented in PVC manufacturing to ensure consistent and reliable PVC products.

Quality control measures in PVC manufacturing

To maintain consistent quality and performance, PVC manufacturers implement various quality control measures throughout the manufacturing process. These measures are designed to identify and rectify any issues that may arise, ensuring that the final PVC products meet the required specifications and standards.

- One of the key quality control measures is the inspection of incoming raw materials. High-quality PVC manufacturers carefully select and test the raw materials they use, ensuring that they meet the required quality criteria. This includes checking the purity of the PVC resin, additives, and any other components used in the manufacturing process.

- During the manufacturing process, regular testing and monitoring are conducted to verify the PVC’s properties and adherence to standards. This includes testing the PVC’s physical properties, such as tensile strength, flexibility, and impact resistance, as well as its chemical resistance to specific substances.

- In addition to testing, manufacturers also implement strict process control measures to ensure consistency and reliability. This includes calibration of equipment, proper blending of additives, and adherence to standardized operating procedures. Regular audits and inspections are carried out to verify compliance with these measures.

- Furthermore, reputable PVC manufacturers invest in research and development to continuously improve their products and processes. They stay updated with the latest advancements in PVC technology and incorporate innovative solutions to enhance the performance and quality of their PVC products.

- By following these quality control measures, PVC manufacturers can deliver consistent, reliable, and high-quality PVC products to their customers. This ensures that the PVC products perform as expected and meet the required standards and specifications.

In the next section, we will discuss the importance of investing in PVC quality, particularly in the construction and other industries where PVC is commonly used.

Ensuring PVC quality in construction and other industries

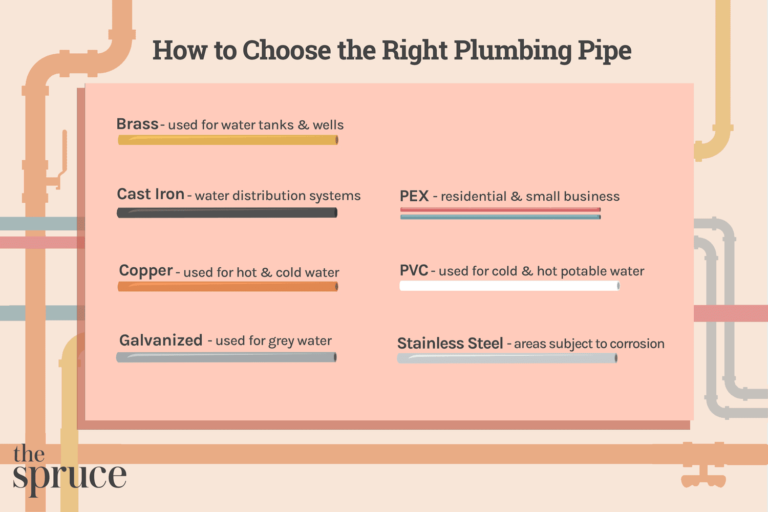

- PVC plays a vital role in various industries, particularly in construction, where it is used for pipes, fittings, roofing, flooring, and many other applications. Ensuring the quality of PVC products in these industries is essential for the success and longevity of projects, as well as the safety of individuals.

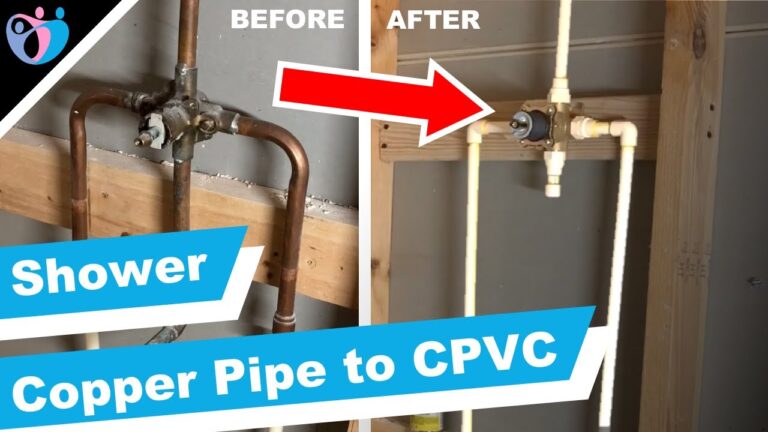

- In construction, PVC pipes are widely used for water supply, drainage, and sewage systems. Poor-quality PVC pipes can lead to leaks, burst pipes, and other plumbing issues. These issues not only result in costly repairs but can also cause water damage and health hazards.

- Similarly, in roofing applications, PVC membranes are commonly used due to their durability and waterproofing properties. Low-quality PVC membranes can lead to leaks, reduced insulation, and premature deterioration, compromising the integrity of the entire roofing system.

- Flooring is another area where PVC quality is crucial. PVC flooring, such as vinyl tiles or luxury vinyl planks, is known for its durability, ease of maintenance, and aesthetic appeal. High-quality PVC flooring products offer excellent wear resistance, impact resistance, and dimensional stability, ensuring long-lasting performance.

- Besides construction, PVC is used in various other industries, such as electrical, automotive, healthcare, and agriculture. For example, PVC electrical cables must meet stringent quality requirements to ensure safe and reliable electrical connections. In healthcare, PVC is used in medical devices, where high-quality materials are essential for patient safety and infection control.

- Investing in PVC quality not only minimizes the risk of issues and failures but also contributes to sustainable and environmentally friendly practices. High-quality PVC products have a longer lifespan, reducing the need for replacements and minimizing waste generation. Furthermore, PVC products that comply with environmental standards ensure minimal impact on the environment throughout their lifecycle.

In the next section, we will provide some tips on choosing a reliable PVC supplier to ensure you get the best quality products for your specific needs.

Choosing a reliable PVC supplier

Selecting a reliable PVC supplier is crucial to ensure you receive high-quality PVC products that meet your requirements. Whether you are a contractor, homeowner, or business owner, following these tips can help you make an informed decision when choosing a PVC supplier:

- Research and reputation: Conduct thorough research and gather information about potential PVC suppliers. Look for suppliers with a solid reputation and positive customer reviews. Check if they have experience in supplying PVC products for your specific industry or application.

- Quality certifications: Look for suppliers that have certifications or accreditations indicating their commitment to quality and compliance with industry standards. These certifications provide assurance that their PVC products have undergone rigorous testing and meet the required quality criteria.

- Product range and customization: Consider the supplier’s product range and whether they offer customization options. A supplier with a wide range of PVC products can cater to diverse needs and applications. Additionally, the ability to customize PVC products allows you to tailor them to your specific requirements.

- Technical support and expertise: Evaluate the supplier’s level of technical support and expertise. A reliable supplier should be able to provide guidance and assistance in selecting the right PVC products for your needs. They should also have knowledgeable staff who can answer any questions or concerns you may have.

- Logistics and delivery: Consider the supplier’s logistics capabilities and delivery options. Ensure that they can deliver the PVC products to your location in a timely and efficient manner. Prompt delivery is essential, especially for time-sensitive projects.

- Price and value: While price is an important factor, it should not be the sole determinant when choosing a PVC supplier. Consider the overall value you get from the supplier, including the quality of their products, customer service, and reliability. It is better to invest in high-quality PVC products that offer long-term durability and performance, even if they come at a slightly higher price.

By following these tips, you can choose a reliable PVC supplier that meets your specific needs and ensures the quality of the PVC products you purchase.

FAQS for What is PVC quality?

Q1: What is PVC quality?

A1: PVC quality refers to the standards and characteristics that determine the overall performance, durability, and safety of polyvinyl chloride (PVC) materials. PVC is a synthetic plastic polymer used in a wide range of applications, and its quality is essential to ensure it meets the desired specifications and functions effectively.

Q2: What are the key characteristics of PVC quality?

A2: The key characteristics of PVC quality include its chemical composition, physical properties, mechanical strength, thermal stability, resistance to environmental factors, and compliance with industry standards. It should also be free from impurities and defects.

Q3: What are the common applications of PVC materials?

A3: PVC materials are commonly used in applications such as piping and plumbing, cable insulation, electrical wiring, vinyl flooring, inflatable structures, medical devices, automotive components, and more.

Conclusion

The importance of investing in PVC quality is a critical factor to consider when purchasing PVC products, whether for construction, electrical, automotive, healthcare, or other industries. High-quality PVC offers superior durability, performance, and safety, ensuring long-term satisfaction and minimizing issues or failures.

Understanding the various factors that contribute to PVC quality, such as the grade of raw materials, manufacturing processes, adherence to standards, and quality control measures, empowers you to make informed decisions and choose the best PVC products for your needs.

By investing in PVC quality, you can enjoy the benefits of durability, reliability, and environmental sustainability. Whether you need PVC pipes, fittings, flooring, or any other PVC product, selecting a reliable PVC supplier and ensuring compliance with industry standards are crucial steps in obtaining high-quality PVC products.

We hope this guide has provided valuable insights into PVC quality and equipped you with the knowledge to make informed decisions in your PVC purchases. Remember, when it comes to PVC, quality matters!