What Is The Full Form Of ASTM Pipe?

The full form of ASTM Pipe is American Society for Testing and Materials Pipe. ASTM Pipe is a type of pipe that is manufactured to meet certain standards set by the American Society for Testing and Materials (ASTM). ASTM Pipe is used in a variety of industrial applications, including oil and gas, petrochemical, and chemical processing. ASTM Pipes are manufactured to meet a variety of specifications and standards, including wall thickness, material type, strength, and chemical composition.

Understanding ASTM Pipe

ASTM pipe is an abbreviation of American Society for Testing and Materials, and is a common form of steel pipe used in a variety of industries. ASTM pipe has been used for years in the construction, automotive, and oil & gas industries and is made from quality raw materials, such as carbon steel and stainless steel. It is a versatile material that can be used for a wide range of applications, including plumbing, piping, and fuel lines. ASTM pipe is also known for its durability, strength, and corrosion resistance.

When it comes to ASTM pipe, there are several different types that are used in various industries, each with its own distinct benefits. For example, ASTM A106 is a type of carbon steel pipe that is commonly used in industrial applications such as boilers, tanks, and heat exchangers. It is also used in the automotive industry for fuel lines and exhaust systems. ASTM A53 is a type of galvanized steel pipe that is commonly used for plumbing and water piping, and is also used in the oil & gas industry for fuel lines.

No matter what type of ASTM pipe you need, it is important to make sure that you purchase quality materials that are strong and corrosion-resistant. ASTM pipe is a great choice for a variety of applications, and with the right pipe, you can be sure that your project will be completed with the utmost precision and quality.

History of ASTM Pipe

ASTM is an abbreviation for American Society for Testing and Materials, which is an international non-profit organization that develops and publishes standards for materials, products, systems, and services. ASTM pipes are the most common type of pipe used in the construction industry and are widely used in residential and commercial applications. These pipes are made from a variety of materials, including steel, copper, plastic, and concrete.

The ASTM standard for pipes was first developed in the late 19th century. The original purpose of the ASTM standard was to provide a uniform system for testing the properties of materials that are used in construction projects. Over the years, the ASTM standard has been revised and expanded to include new standards for testing the strength, durability, and quality of pipes. Today, ASTM pipes are used in a wide variety of applications, including gas and water lines, sewage systems, irrigation systems, and more.

The ASTM standard for pipes is designed to ensure the quality and safety of all pipes, regardless of the type of material used. The testing process for ASTM pipes involves several tests to determine the strength, durability, and quality of the pipes. The tests evaluate the material’s ability to withstand pressure, its resistance to corrosion, and its ability to resist cracking or breaking. ASTM pipes are also tested for their ability to withstand temperature changes, chemical exposure, and other environmental conditions.

ASTM pipes are one of the most reliable and cost-effective materials used in the construction industry. The ASTM standard for pipes ensures that they are safe and reliable for use in residential and commercial applications.

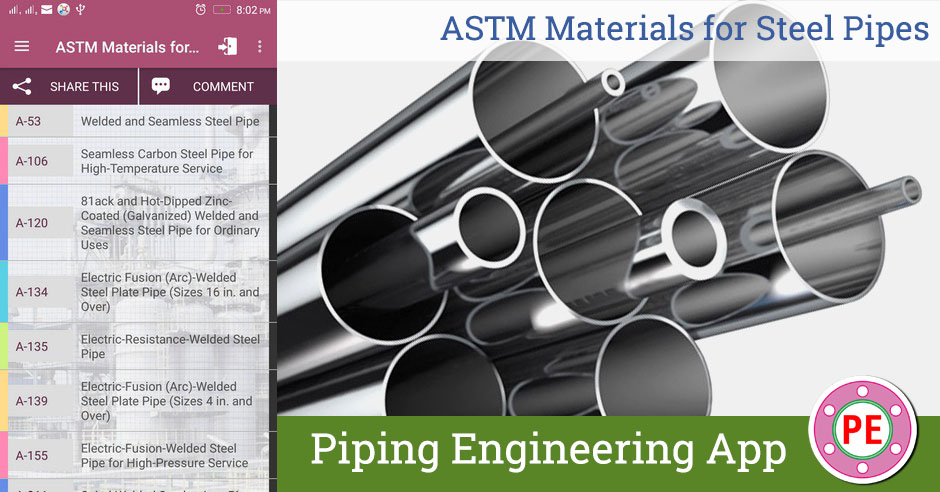

Types of ASTM Pipe

ASTM A106 is another type, specifically designed for high-temperature service, making it suitable for applications in power plants and petrochemical facilities. ASTM A312, on the other hand, focuses on seamless and welded stainless steel pipes, making it ideal for applications where corrosion resistance is essential, such as in the food and chemical industries. Each type of ASTM pipe has its own set of properties and characteristics that make it suitable for different applications. ASTM A53 is the most common type of ASTM pipe, which is suitable for water and structural applications. Other ASTM pipe types include ASTM A252 for piling, ASTM A106 for high-temperature service, ASTM A333 for low-temperature service, and ASTM A500 for cold-formed welded and seamless carbon steel structural tubing. Depending on the application, the ASTM pipe will need to be selected based on its properties and characteristics.

ASTM pipes are widely used in various industries due to their superior mechanical properties, corrosion resistance, and highly efficient production process. ASTM, or American Society for Testing and Materials, is an organization that sets standards for the production of metals and pipes. ASTM pipes are known for their consistency in dimensions, materials, and other important characteristics. This ensures that the pipes produced are of the highest quality and provide the best performance possible.

The advantages of ASTM pipe over other types of pipes include higher strength, increased durability, and corrosion resistance. ASTM pipes are also known for being easy to install, lightweight, and able to withstand extreme temperatures. ASTM pipes are also made from a variety of metals, including stainless steel, aluminum, and titanium, making them suitable for a wide range of applications. Furthermore, ASTM pipes are cost-effective and available in various sizes and grades, making them a great option for any project.

Overall, ASTM pipes are an excellent choice for many industries, as they provide superior performance and durability. Their cost-effectiveness and availability in various sizes make them a great option for any project. The high quality of the materials and manufacturing process ensures that the pipes produced are of the highest quality and provide the best performance possible.

Disadvantages of ASTM Pipe

ASTM pipes are widely used in many industries, ranging from construction and engineering to automotive and furniture. However, ASTM pipes also come with some potential drawbacks. While the advantages of using ASTM pipes may be worth the potential risks, it is important to consider the negative aspects of using these pipes before making a decision.

One of the main disadvantages of using ASTM pipes is their susceptibility to corrosion. Since these pipes are made from metals, they can be damaged by water and other corrosive substances. Without proper maintenance, these pipes can easily develop rust and other issues. This can reduce the overall life of the pipes and cause them to fail prematurely.

Another concern with ASTM pipes is their cost. These pipes can be expensive compared to other types of pipes, making them unaffordable for some people. This is especially true when the pipes need to be imported or custom-made. Additionally, the cost of labor to install the pipes can be high, as the installation process is often complex and time-consuming.

Finally, ASTM pipes can be difficult to repair if they are damaged. It is often necessary to replace entire sections of the pipes, rather than just patching up the damaged area. This can add to the overall cost of the repair and can lead to further problems if the installation is not done correctly.

By understanding the potential disadvantages of using ASTM pipes, consumers and businesses can make informed decisions about which type of pipes to use for their projects. While the pipes may offer many advantages, it is important to take the potential risks into consideration.

FAQs About the What Is The Full Form Of ASTM Pipe?

Q1. What is the full form of ASTM pipe?

A1. The full form of ASTM pipe is American Society for Testing and Materials.

Q2. What is the purpose of ASTM pipe?

A2. ASTM pipe is typically used in the construction industry for a variety of applications such as plumbing and piping. It is used to provide structural integrity and pressure resistance.

Q3. How is ASTM pipe made?

A3. ASTM pipe is made from a variety of materials such as steel, stainless steel, copper, and aluminum. The material is formed into pipes using a variety of methods, such as welding, rolling, and pressing.

Conclusion

The full form of ASTM Pipe is American Society for Testing and Materials Pipe. ASTM Pipe is a type of pipe used for transporting fluids and gasses. It is made from a variety of materials, including steel, stainless steel, copper, brass, and plastic. ASTM Pipe is available in a range of sizes and is used in a variety of applications, including plumbing, heating, and industrial purposes. ASTM Pipe is a reliable and safe choice for many applications.