What Is The Full Form Of CPVC?

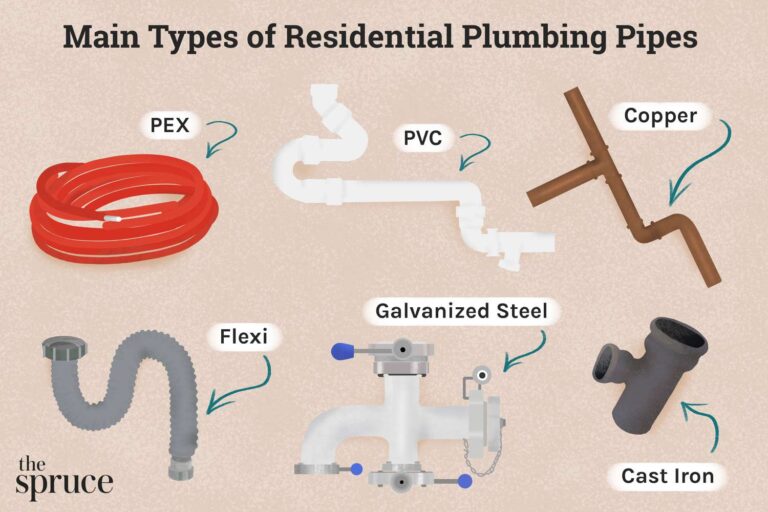

CPVC stands for Chlorinated Polyvinyl Chloride. It is a type of plastic that is produced through the chlorination of polyvinyl chloride (PVC) resin. CPVC is used mostly in hot and cold potable water systems, and it is highly resistant to corrosion and chemical degradation. It is also fire-resistant and has a higher temperature and pressure rating than PVC. CPVC is used in a variety of applications including pipes, fittings, valves, and other plumbing components.

Definition and Origin of CPVC

CPVC, or chlorinated polyvinyl chloride, is a thermoplastic polymer used in construction and engineering applications. It is a type of plastic that is stronger, more durable, and more resistant to damage from fire, chemicals, and high temperatures than its predecessor, PVC. CPVC is used in a variety of applications, from plumbing and piping to windows and doors. It is also becoming increasingly popular in the medical, automotive, and aerospace industries.

The full form of CPVC is chlorinated polyvinyl chloride, which is a type of plastic that has been modified to be more resistant to fire, chemicals, and higher temperatures compared to conventional PVC. It was developed in the early 1960s by British company B.F. Goodrich and has since become a widely used material in the construction, engineering, automotive, and other industries. CPVC is an excellent choice for piping, plumbing, and other applications that require heat resistance, chemical resistance, strength, and durability. CPVC is also highly cost-effective, making it an attractive option for many projects.

Properties of CPVC

make it a great choice for plumbing and water supply systems. CPVC stands for Chlorinated Polyvinyl Chloride, a thermoplastic material that has excellent heat-resistance and chemical resistance properties. CPVC has a higher temperature rating than PVC, making it a great choice for hot water systems and applications that require higher temperatures. In addition to its heat-resistance, CPVC is also resistant to a variety of chemicals, including acids and bases, making it useful in a wide variety of industrial applications. CPVC is also less expensive than other thermoplastic materials and has a long life span, making it a cost-effective choice. As a result, CPVC is widely used in commercial and residential plumbing and water supply systems, as well as in a variety of other industrial applications. The wide range of uses and excellent properties of CPVC make it a great choice for many applications.

Advantages of CPVC

CPVC or Chlorinated Polyvinyl Chloride is a thermoplastic material used for a variety of applications, including piping, plumbing, and construction. It is a highly durable and economical material, and is used in numerous industries. CPVC offers several advantages over traditional materials, such as increased strength, corrosion resistance, and flame resistance. Additionally, CPVC can be used in temperatures up to 200°F (93°C) without any loss in performance. It is also easy to install and is compatible with existing plumbing systems, making it a great choice for both residential and commercial applications. CPVC is also a great choice for high-pressure systems, as it is capable of withstanding up to 600 psi. In terms of cost, CPVC is often less expensive than metal piping or other plastic varieties. With its wide range of benefits, CPVC is sure to provide a reliable and cost-effective solution for any project.

Disadvantages of CPVC

CPVC (chlorinated polyvinyl chloride) is a type of plastic piping used in residential and commercial plumbing systems. It is a good alternative to traditional copper piping because of its durability, corrosion resistance, and affordability. However, there are some disadvantages to using CPVC in plumbing applications that should be considered before opting for it.

Firstly, CPVC is not as flexible as copper or other types of plastic piping, making it difficult to install in tight spaces. In addition, CPVC is more prone to leaks than copper and other alternatives because of its rigid nature. It also requires more fittings to connect, which can add to the cost and time of the installation.

Another disadvantage of CPVC is that it is not as resilient to high temperatures as copper. It can become brittle or even melt under extreme temperatures, resulting in leaks or even catastrophic failures. For this reason, CPVC is not recommended for applications that involve hot water or other high-temperature liquids.

Finally, CPVC is not as resistant to the chemicals found in some cleaning products as copper piping. This can lead to corrosion and eventual failure of the pipe over time.

Despite these drawbacks, CPVC still remains a popular choice for many plumbing applications. It is important to weigh all the pros and cons before deciding on whether or not to use CPVC in a particular situation.

Applications of CPVC

Are numerous and versatile. It is a thermoplastic material that is strong and lightweight, making it a popular choice for plumbing, construction, and industrial applications. CPVC stands for chlorinated polyvinyl chloride, and is a type of plastic polymer that is chemically altered to make it resistant to heat and corrosion. It can withstand temperatures of up to 200°F, making it ideal for hot water applications, such as potable water lines or radiant heating systems. Additionally, CPVC is highly durable and is resistant to the growth of bacteria, fungi, and other microorganisms, making it a popular choice for medical and laboratory settings. CPVC is also a cost-effective alternative to traditional metal and copper piping, as it is easier to install and less expensive to maintain. CPVC is available in a variety of shapes and sizes, making it suitable for a variety of applications. With its strength, durability, and resistance to heat and corrosion, CPVC is a great choice for many types of projects and applications.

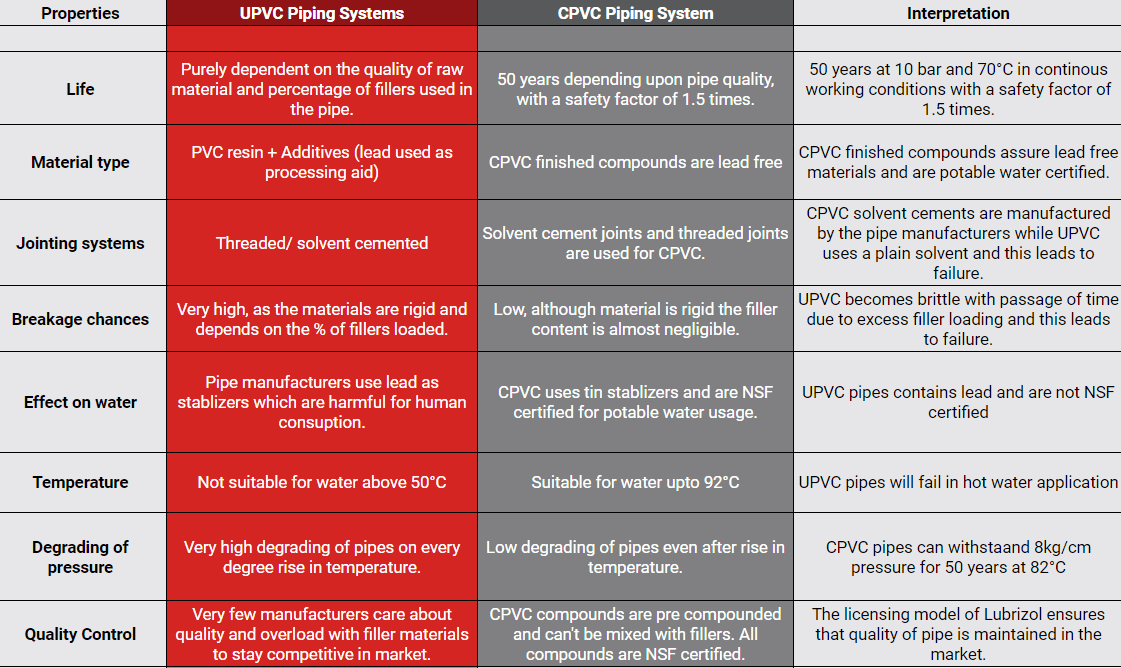

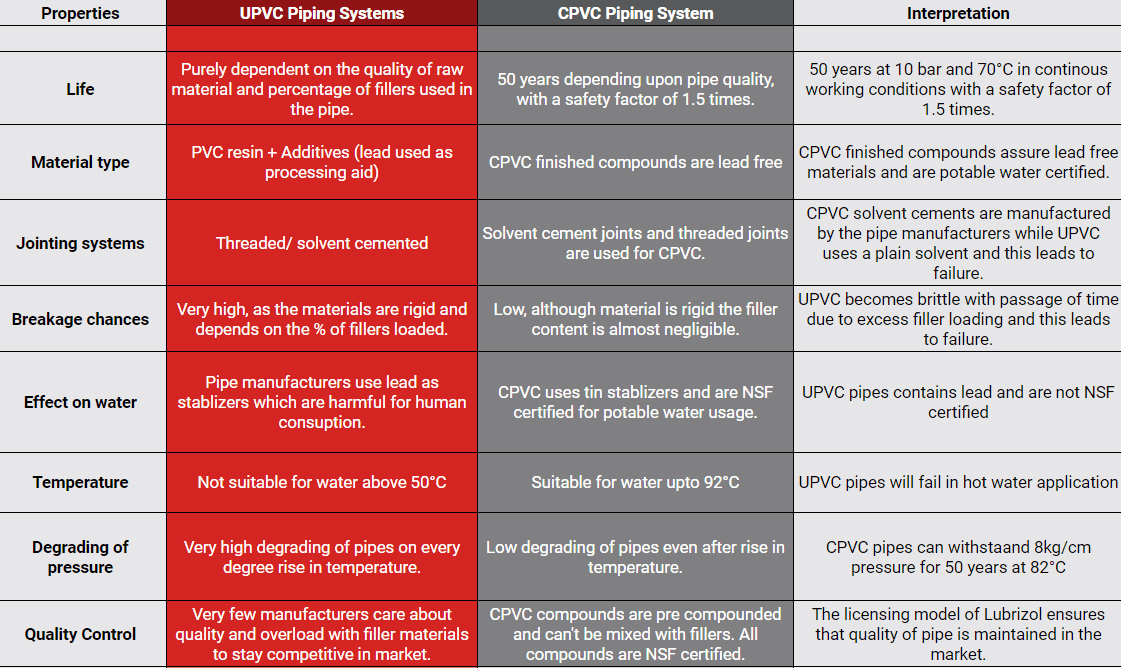

Comparison of CPVC to Other Materials

CPVC (Chlorinated Polyvinyl Chloride) is an engineered thermoplastic material that has become increasingly popular in construction and industrial applications, due to its superior mechanical and chemical properties. When compared to other materials, CPVC stands out for its durability, cost-effectiveness, and versatility.

CPVC is more durable than many other materials, such as polypropylene and PVC, and it has excellent resistance to most chemicals, including acids and alkalis. It is also resistant to corrosion and abrasion, which makes it ideal for applications that require long-term performance and durability. Additionally, CPVC is more cost-effective than metal, and it is easier to install than metal piping systems.

CPVC is also a versatile material that can be used in a variety of applications. It is suitable for plumbing, HVAC systems, and chemical processing, as well as for underground piping systems. It is also well-suited for hot and cold water distribution, as well as for food processing applications. Furthermore, CPVC can be used in both interior and exterior applications, making it a suitable choice for a wide range of applications.

CPVC is an engineered thermoplastic material that has many advantages over other materials. It is durable, cost-effective, and versatile, making it a great choice for a variety of applications. Additionally, it is easy to install and maintain, making it an ideal choice for both residential and commercial applications.

FAQs About the What Is The Full Form Of CPVC?

Q1. What is the full form of CPVC?

A1. CPVC stands for Chlorinated Polyvinyl Chloride.

Q2. How is CPVC different from other types of plastic pipes?

A2. CPVC is more durable than PVC and is resistant to corrosion and chemicals. It is also more flexible and has a higher temperature tolerance, making it suitable for hot water lines.

Q3. What are the benefits of using CPVC piping?

A3. CPVC piping provides a long-lasting and cost-effective solution for a variety of plumbing applications. It is easy to install, lightweight, and resistant to corrosion and chemicals. It also has excellent temperature tolerance and is approved for potable water applications.

Conclusion

The full form of CPVC is Chlorinated Polyvinyl Chloride. CPVC is a strong, durable thermoplastic material that is highly resistant to corrosion and chemical attack. It is often used in piping systems to carry liquids and gases, and is also used in electrical insulation and medical equipment. CPVC has been used extensively in the construction industry due to its excellent properties such as chemical resistance, flame retardancy, and low costs.