What Material Is PVC?

Polyvinyl chloride (PVC) is a versatile and durable plastic material used in a wide variety of applications. PVC is lightweight, strong, and resistant to corrosion and chemicals. It is also inexpensive, making it a popular choice for many industrial, commercial, and residential projects. PVC can be used to make pipes, fittings, and valves for plumbing systems; windows and doors; roofing materials; packaging materials; and many other products. PVC is also flame-resistant and can be used to make electrical wiring insulation.

Background and History of PVC

PVC, or polyvinyl chloride, is a versatile and cost-effective material used in a variety of applications. But what exactly is PVC and where did it come from? To answer these questions, it’s important to look at the history and development of PVC.

The origins of PVC date back to 1835, when Charles Goodyear stumbled upon vulcanization, a process that transforms rubber into a harder and more durable material. Then, in the late 19th century, German chemists discovered that vinyl chloride could be polymerized to form a plastic material. The first commercial PVC product was produced in the 1920s.

Since then, PVC has become one of the most widely used plastics in the world. It is light-weight, highly durable, and resistant to corrosion, making it the perfect choice for a variety of applications. PVC is commonly used for pipes, wiring, and even medical equipment. Its versatility, affordability, and resistance to weathering make it an ideal building material for both residential and commercial construction.

Today, PVC is used in a variety of products, from medical equipment to furniture and even flooring. As its popularity continues to grow, the possibilities for PVC are endless.

Characteristics of PVC

Polyvinyl Chloride (PVC) is a thermoplastic polymer of vinyl chloride widely used in construction and industrial applications. It is one of the most common plastics in use, with over 40 million tons of PVC produced annually. PVC is incredibly versatile and can be used to create a variety of products, including pipes, window frames, medical supplies, and much more. So, what makes PVC so special? Let’s take a look at the characteristics of PVC that make it such a great material for so many applications.

PVC is incredibly durable and resistant to corrosion, making it great for use in areas that are exposed to harsh weather or chemicals. It is also non-toxic, non-flammable, and non-conductive, making it a safe choice for many products. Additionally, PVC is lightweight, yet has a high strength-to-weight ratio, making it ideal for applications where weight is a concern. PVC is also easy to work with, making it a great choice for custom applications. Lastly, PVC is relatively inexpensive, making it a cost-effective solution for many applications.

In conclusion, PVC is a great material for many applications due to its durability, strength-to-weight ratio, non-toxicity, and affordability. If you’re looking for a versatile material for your next project, PVC is definitely worth considering.

Types of PVC

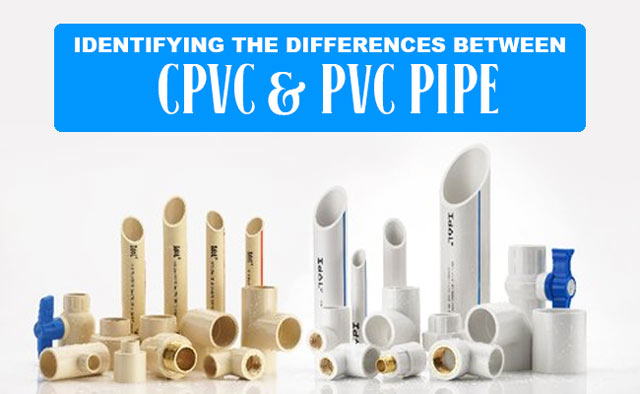

Polyvinyl chloride, commonly known as PVC, is a type of plastic commonly used in construction and manufacturing. PVC is strong, durable, and inexpensive, making it an ideal material for a wide range of applications. But it’s important to understand the different types of PVC and how they can be used.

PVC comes in two main forms: rigid and flexible. Rigid PVC is rigid and hard, making it ideal for window frames, pipes, and other construction material. Flexible PVC is soft and pliable, making it great for electrical cables and outdoor clothing. PVC can also be mixed with other materials to create a composite material; for instance, PVC can be combined with glass fibers to create a strong, lightweight material.

PVC is also available in different grades, based on its intended use. For instance, there are food-grade PVCs, electrical-grade PVCs, and industrial-grade PVCs. Each grade is formulated to meet specific requirements and provide the best performance for its intended use.

No matter the application, PVC is a versatile and cost-effective material for a wide range of projects. By understanding the different types and grades of PVC, you can make sure you get the best material for your project.

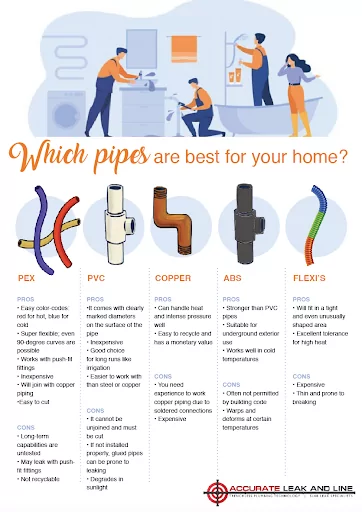

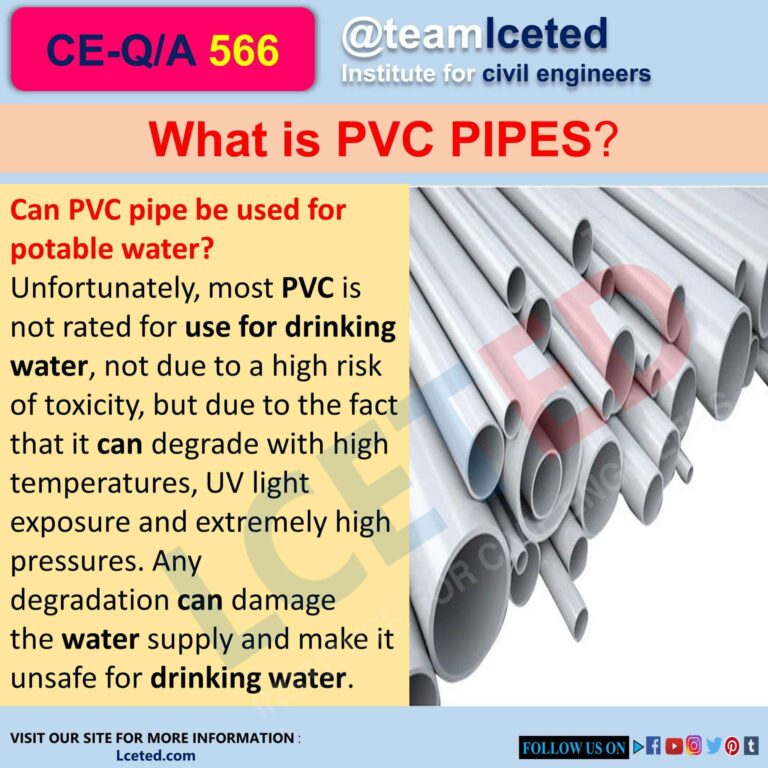

Uses of PVC

PVC, or polyvinyl chloride, is a versatile and popular material used in a variety of applications. It is a strong, durable, and flexible plastic that is highly resistant to corrosion and weathering. PVC is also lightweight and easy to install, making it a popular choice for many projects. It is used for a variety of applications, including plumbing systems, window and door frames, electrical wiring, furniture, and more. PVC is also used to create products such as pipes, fittings, sheets, and films. Its ability to withstand extreme temperatures, chemicals, and moisture make it an ideal choice for many projects. It is also an affordable option compared to other materials, making it a popular choice for businesses and homeowners alike. In addition, its recyclability makes it an environmentally friendly choice. PVC is a versatile material that is used in many different applications, making it a popular choice for many projects.

Pros and Cons of PVC

PVC (polyvinyl chloride) is one of the most popular materials used in the construction industry due to its affordability, durability and versatility. PVC is most often used to make piping, window frames, roofing tiles and cladding. However, there are both advantages and disadvantages to using this material.

The primary advantage of PVC is that it is highly resistant to corrosion and weathering, making it an ideal choice for outdoor applications. PVC is also relatively inexpensive and easy to install, making it a popular choice for DIY projects. Additionally, PVC is highly fire resistant, making it a safer alternative to other materials.

On the other hand, PVC can be difficult to work with, as it requires specialized tools and techniques. Additionally, it is not as strong as some other materials, and it is prone to cracking under high temperatures or exposure to certain solvents. Finally, PVC is not biodegradable, which can have a negative environmental impact.

In conclusion, PVC is a popular choice in the construction industry due to its affordability, durability and versatility. However, it is important to consider the pros and cons of using this material before making a decision. Careful consideration should be given to the specific application and environment in which the material will be used.

PVC Alternatives

PVC (polyvinyl chloride) is a widely used material for construction and DIY projects. But what if you want a more environmentally friendly alternative? There are a few materials that can be used as an alternative to PVC in some applications.

Recycled plastic is one of the best substitutes for PVC. It is usually made from recycled plastic bottles and other containers and is available in a wide variety of colors and textures. Recycled plastic is durable, weather-resistant, and non-toxic, making it an ideal material for outdoor applications.

Another option is hemp-based composite, which is derived from the hemp plant. Unlike PVC, hemp-based composite is renewable, non-toxic, and recyclable. It is also highly durable and resistant to UV rays, making it ideal for outdoor applications.

Finally, bamboo-based composite is a great alternative to PVC. Bamboo is a renewable resource and is extremely strong and durable. Bamboo-based composite can be used in applications such as furniture, flooring, and siding. It is also non-toxic and environmentally friendly.

PVC is a great material for many projects, but there are alternatives available that can help reduce the environmental impact of your project. Recycled plastic, hemp-based composite, and bamboo-based composite are all viable options that are non-toxic, durable, and renewable. Consider these alternatives when deciding on a material for your next project.

FAQs About the What Material Is PVC?

1.Q: Is PVC an environmentally friendly material?

A: PVC can be a sustainable material when it is recycled. It can be recycled into new products such as pipes, flooring, siding, and more.

2.Q: What types of products can be made with PVC?

A: PVC is a versatile material that can be used to create a variety of products, including pipes, window frames, siding, flooring, and more.

3.Q: Is PVC a durable material?

A: Yes, PVC is a strong and durable material that is resistant to corrosion, chemicals, and water damage. It is also more affordable than other building materials.

Conclusion

PVC, or polyvinyl chloride, is a type of plastic that is strong and durable. It has many uses, such as plumbing, electrical insulation, flooring, and more. PVC is versatile and easy to work with, making it a popular choice for many applications. It is also moisture and chemical-resistant, and is often used in water pipes and medical equipment. PVC is an economical and sustainable material, making it a great choice for a variety of projects.